China Wholesale Auger Filler Packing Machine Suppliers – Automatic Vertical Packing Machine – Shanghai Tops Detail:

Application for pouch packing machine

Fully automatic pouch packing machine can do bag forming, filling and sealing automatically. Automatic pouch packing machine can work with auger filler for powder material, such as, washing powder, milk powder etc. small pouch packing machine also can work with linear weigher or multihead weigher for Irregularly granulated material including puffed food, Candy sugar, etc.

Features for liquid pouch packing machine

■ Computerized touch screen, easy to adjust and operate, and easy to change products, with exception appearance system, easily and rapidly to repair;

■ The movement of horizontal seal frame is controlled by the transducer, the moving speed of the horizontal seal frame can be adjusted on the touch screen voluntary;

■ The encoder controls the working time of vertical seal, horizontal seal, cutter ect moving elements accurately, and it can be adjusted on the touch screen;

■ Could be automatically to finish making bags, sealing, printing, and optional functions: connected bags system, European style hole punching, nitrogen system, etc;

■ Design with alarming for clipping material, door unclosed, rolled film on wrong position, no print tape, no rolled film etc.; can be adjusted on the touch screen for the film running deviation;

■ The advanced design ensures that it is very convenient for adjustment, operation and maintenance when different profession use;

■ Can be assorted with all kinds of automatic metering equipment home and abroad.

Technical parameters for spice pouch packing machine

| Model | TP-V302 | TP-V320 | TP-V430 | TP-V530 |

| Package Size | Triangular bag: L=20-250 mm W=20-75 mm; Pillow bag: L=20-250 mm W=20-160 mm |

L=50-220mm W=30-150 mm | L=80-300mm W=60-200mm | L=70-330mm W=70-250mm |

| Packing speed | 35-120 bags/min | 35-120 bags/minute | 35-90 bags/min | 35-90 bags/minute |

| Pulling Belt Type | Horizontal sealing device | Horizontal sealing device | By belt | By belt |

| Electrical and power supply | AC220V,50-60Hz,3KW | AC220V, 50-60Hz,3KW | AC220V,50-60Hz,3KW | AC220V,50-60Hz,3KW |

| Compressed air consumption | 0.6MPA 250NL/min | 0.6MPA 250NL/min | 0.6MPA 250NL/min | 0.6MPA 250NL/min |

| Total weight | 390kg | 380kg | 380kg | 600kg |

| Dimension | L1620×W1160×H1320 | L960×W1160×H1250 | L1020×W1330×H1390 | L1300×W1150×H1500 |

Optional configuration for pouch packing machine price

1) Printer

2) gusseting device

3) Inflator equipment

4) Pothook/ holes-punching functions (round or Euro slot/hole and others)

5) Pre-clamping device of horizontal sealing

6) Product-clip device of horizontal sealing

7) Automatic sales promotion card-sending device

8) Automatic sales promotion film strip device outside of the bag

Detailed Photos for pouch packing machine manufacturer

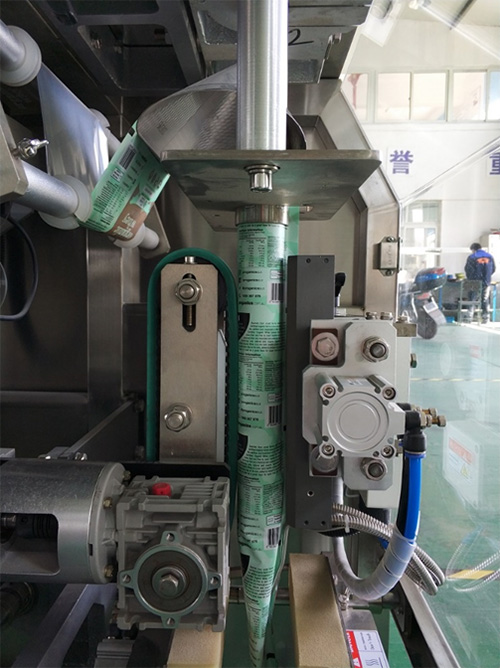

1. Collar type bag former

The bag is more beautiful and tidy, with higher accuracy

2. Film pulling system

Servo drive for film feed system and vacuum allows for accurate positioning and easy to adjust

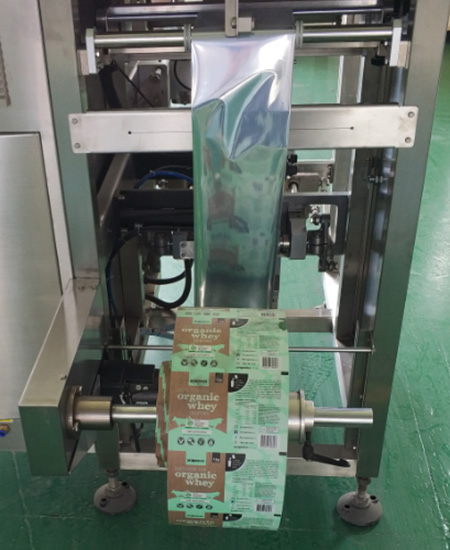

3. Film System

A mandrel allows quick & easy film changes

4. Code printer

5. Sealing and cutting part

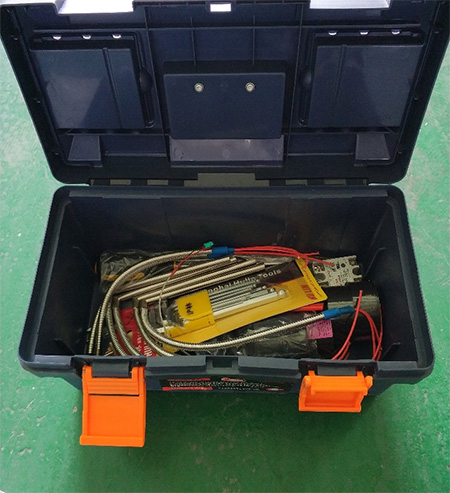

6. Tool kit

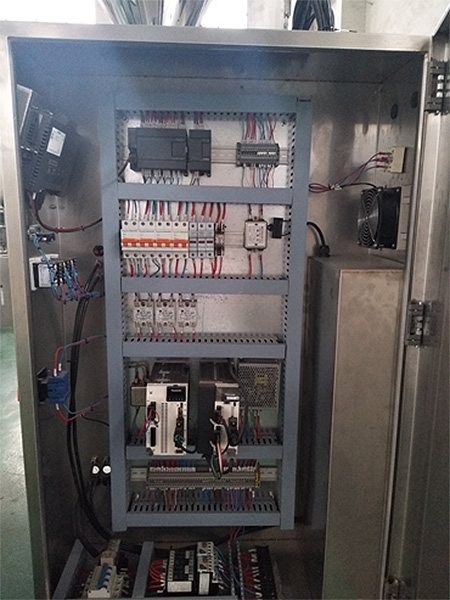

Electric cabinet: Siemens touch screen, Panasonic driver and PLC.

Computerized touch screen, easy to adjust and operate, and easy to change products, with exception appearance system, easily and rapidly to repair

Works with auger filler for

packing powder products

Works with linear weihger or multihead weigher for packing granular products

Machine maintenance

The shaft and bearing should be lubricated regularly.

Product detail pictures:

Related Product Guide:

In an effort to finest meet up with client's requirements, all of our operations are strictly performed in line with our motto "High High quality, Competitive Rate, Fast Service" for China Wholesale Auger Filler Packing Machine Suppliers – Automatic Vertical Packing Machine – Shanghai Tops, The product will supply to all over the world, such as: Bhutan, Japan, Latvia, Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.

-

China Wholesale Chilli Powder Packing Machine M...

-

Best High Quality Injectable Powder Filling Mac...

-

China Wholesale Small Auger Filling Machine Fac...

-

Best High Quality Powder Blender Manufacturers ...

-

Best High Quality Powder Pouch Filling Machine ...

-

China Wholesale Automatic Rotary Pouch Packing ...