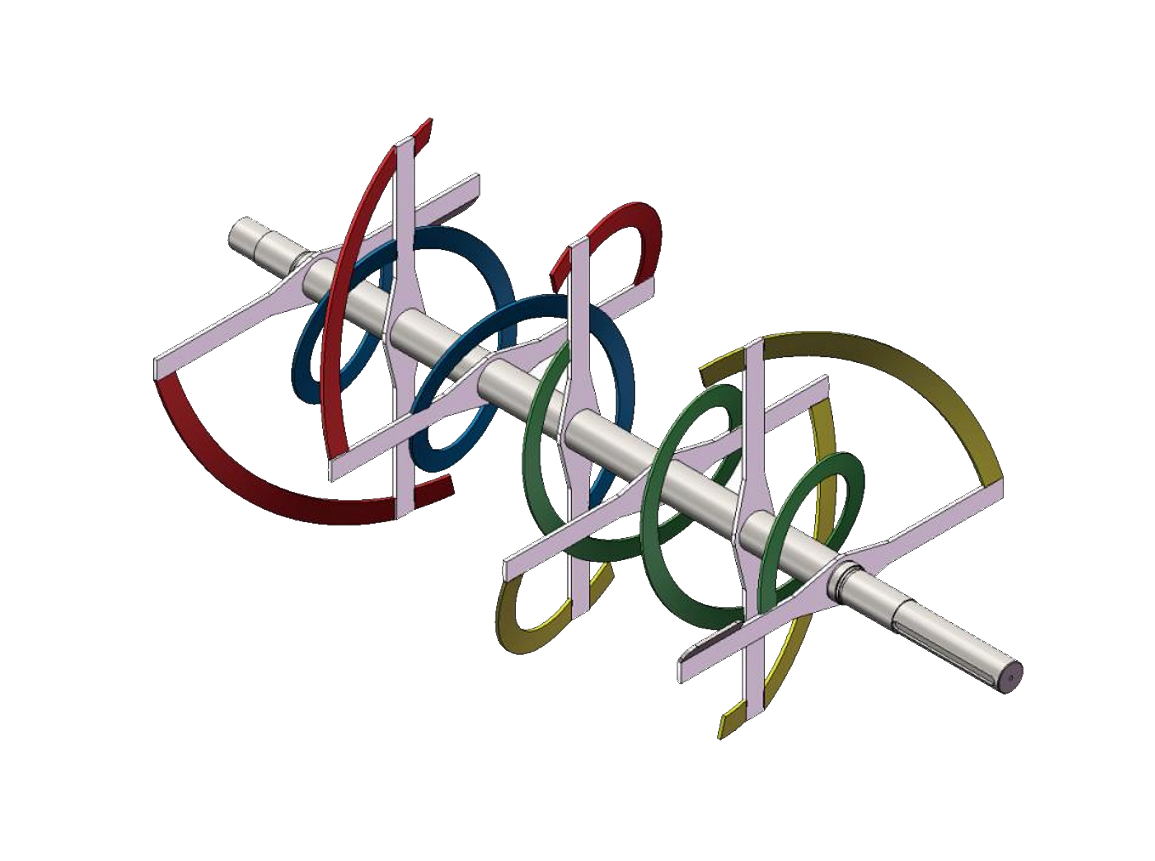

The Ribbon Blender operates on the following fundamental principles: products are filled into the mixing tank, the machine is powered to move the rotating shaft and double ribbon agitator, and the mixed materials are discharged.

Adding materials to the mixing tank and blending them:

The mixing tank is filled with materials. While the machine is operating, the product is pushed from the sides for convective mixing by the inner ribbon, which moves the material from the sides to the middle of the tank.

Release of the Powder:

The blended materials are released from the machine by opening the discharge valve at the bottom once the products have been well mixed.

Fill Volumes:

The ribbon blender relationship of machines functions by fill volume instead of the mixing tank's maximum weight capacity. This is due to the fact that a powder mix's bulk density may affect how much it weighs.

Only a fraction of the whole tank volume is represented by the maximum fill volume of the mixing tank in the ribbon mixing. The bulk density of the powder product being applied is the basis for determining this maximum fill volume.

Post time: Nov-03-2023