Let's begin by talking about the design of ribbon blender in today's blog.

If you're wondering what the major uses of a ribbon blender are, they're widely used in a variety of industries, including construction, food processing, chemicals, and pharmaceuticals. It is used to blend powder with liquid, powder with granules, and powder with other powder. The twin ribbon agitator, which is powered by a motor, speeds up the convective mixing of ingredients.

Normally, a ribbon blender's design includes the following parts:

U-form Design:

The blender's main structure is designed like a U. Complete welding is used to connect every component. Easy to clean up after mixing, and no powder leftovers. The whole machine is made of stainless steel 304 or 316 materials, depending on the demand for clients, as well as the ribbon and shaft, as well as the inside of the mixing tank, which is fully mirror polished.

Ribbon Agitator:

An inner and an outer helical agitator compose the ribbon agitator. The material is moved by the inner ribbon from the center to the outside, and the outer ribbon rotates as it moves the material from the two sides to the center. Ribbon blenders combine ingredients quickly without sacrificing quality.

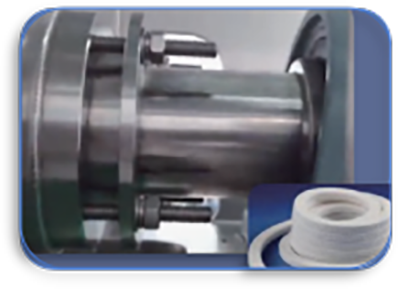

The ribbon blender's shaft and bearings:

It helps to ensure consistent performance during the mixing process, as well as reliability and rotational ease. A leak-free operation is ensured by our proprietary shaft sealing design, which incorporates the German Burgan packing gland.

Motor Drive:

It is an important part because it gives them the power and control, they need to mix effectively.

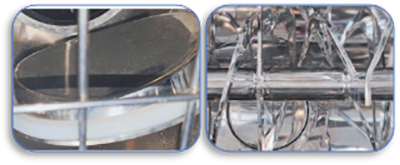

Discharge Valve:

During mixing, a slightly concave flap at the bottom center of the tank guarantees good sealing and removes any dead angles. When the mixing is done, it is poured out of the blender.

Safety Features:

1. The slow-rising design guards against cover falls that could endanger operators and guarantees the longevity of the hydraulic stay bar.

2. The manual loading procedure is made easier, and the operator is kept safe from the revolving ribbons by the safety grid.

3. During ribbon rotation, worker safety is guaranteed by an interlock device. When the cover is opened, the mixer stops working automatically.

Post time: Feb-22-2024