Video

Operating principle

How does screw capping machine work?

6 sets single motor drive 3sets rotary wheels to screw the caps which fixed on the bottles/ jars correctly. And it's continuously running, greatly increasing its capping speed.

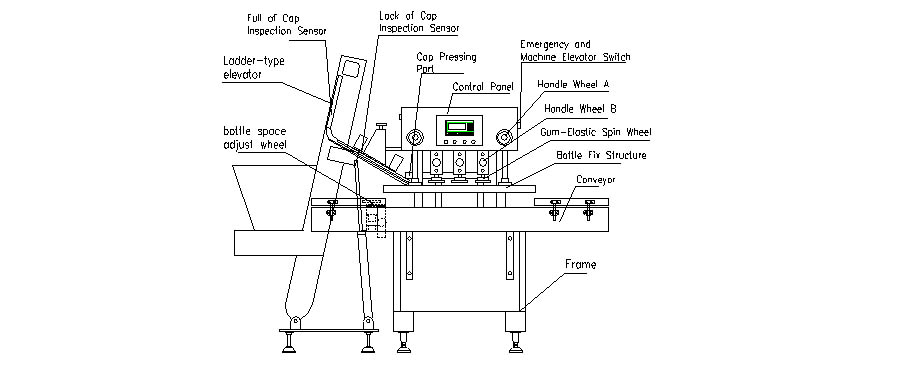

Screw Capping machine constituent Part

Consist of

1. Cap elevator

2. Auto conveyor

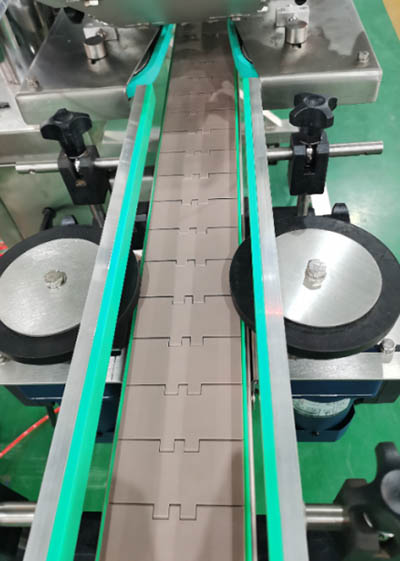

3. Screw wheels

4. Touch screen

5. Adjusting hand-wheels

6. Foot cups and Casters

Key features

■ Whole machine with full SS304 material.

■ Capping speed up to 40-100 CPM.

■ One button to adjust the screw wheels height by electricity.

■ Wide applicability and easy adjust for various caps and bottles.

■ Auto stop and alarm when lack of cap.

■ 3 sets of tightening discs.

■ No-tool adjustment.

■ Choice of various types of cap feeders.

Description

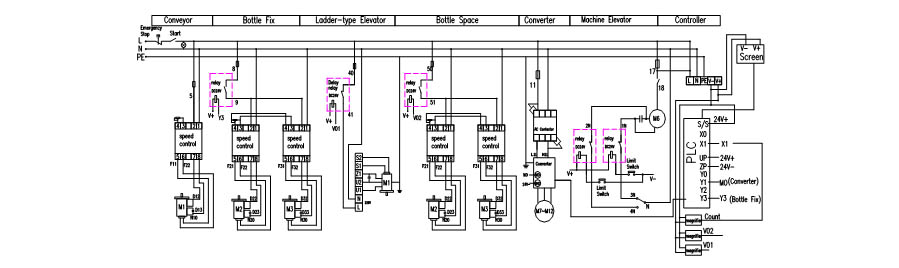

This model auto screw capping machine is economical, and easy to operate. equipped with microcomputer, the control system adopts SLSI system, and display working information by digital numbers, which is easy to read and input. It can connect with other packaging line or work individually.

It can handles a wide range of containers at speeds up to 100 bpm and offers a quick and easy changeover that maximizes production flexibility. The tightening discs are gentle which will not damage caps but with an excellent capping performance. Compared with traditional intermittent working capper, it works faster and the capping performance is better. The innovation design such as automatic cap elevator feeding system, straightway bottle feeding and continual capping also raise the production capacity.

Details

1. Automatic Cap elevator, can easy change the channel width and height by hand-wheel to apply for various sizes caps.

2. Hand-wheels with dial to adjust the rotary wheels space, it is to adjust the torque.

3. Reverse switch and emergency stop button, reverse switch is to change the first sets wheels reverse rotary, it will for specific cap to correct setting on the bottle/jar's mouth.

4. The space adjusting wheel can adjust tandem space of the bottle when it is passing by. The speed of bottle space adjusting wheel can be controlled by knob on the control panel.

5. Foot cups and Casters, it will be easy to move the machine to anywhere, or very stably fixed to work on the ground.

6. Knobs to adjust speed of the conveyor, bottle fix, cap arrange, bottle space.

7. Electrical control cabinet use famous brand electrical accessories to ensure stability of machine performance.

8. This is cap pressing part, it will bring pressure to bear on the cap when the cap was rotated by the spin wheel.

9. Delta brand touch screen, Chinese and English interface.

Main parameter

| Capping Speed | 50-200 bottles/minutes |

| Bottle diameter | 22-120mm ( customized according to requirement ) |

| Bottle height | 60-280mm (customized according to requirement ) |

| Cap diameter | 30-60mm (customized according to requirement ) |

| Power source and consumption | 1300W, 220v, 50-60HZ, single phase |

| Dimensions | 2100mm×900mm×1800 mm ( Length × Width × Height ) |

| Weight | 450 kg |

| Compressed air | 0.6MPa |

| Feeding direction | left to right |

| Working temperature | 5~35℃ |

| Working humidity | ≤85%, No clotted dew |

Front view

Operation procedure

1. Put some bottle on the conveyor.

2. Install the cap arranging (Elevator) and dropping system.

3. Adjust the size of chute based on the specification of cap.

4. Adjust the position of railing and bottle space adjusting wheel according to the diameter of bottle.

5. Adjust the height of bottle fixed belt based on the height of bottle.

6. Adjust the space between two sides of bottle fixed belt in order to fix the bottle tightly.

7. Adjust the height of gum-elastic spin wheel to match the position of cap.

8. Adjust the space between two sides of spin wheel according to the diameter of cap.

9. Press the power switch to start running machine.

Accessories brand

|

Model |

Specification |

Brand |

Manufactory |

|

Capping Machine TP-CSM- 103 |

Converter |

DELTA |

DELTA Electronic |

|

Sensor |

AUTONICS |

AUTONICS Company |

|

|

LCD |

TouchWin |

SouthAisa Electronic |

|

|

CPU |

ATMEL |

Made in USA |

|

|

Connection Chip |

MEX |

Made in USA |

|

|

Elastic gum for spin wheel |

|

Rubber research institute (ShangHai) |

|

|

Series motor |

TALIKE |

ZHONGDA Motor |

|

|

Stainless steel |

304 |

Made in Korea |

|

|

Steel frame |

Bao steel in Shanghai |

||

|

Aluminium & alloy parts |

LY12 |

Parts list

|

No. |

Specification |

Quantity |

Unit |

Remark |

|

2 |

Power wire |

1 |

Piece |

Including a set of hex wrenches (﹟10, ﹟8,﹟6,﹟5,﹟4), two pieces of screwdriver, a piece of adjustable spanner(4″) |

|

3 |

Fuse 3A |

5 |

Piece |

|

|

4 |

Spin wheel |

3 |

Pair |

|

|

5 |

Bottle fix belt |

2 |

Piece |

|

|

6 |

Speed controller |

1 |

piece |

Diagram of electrical principle

Optional

Unscrambling turning table

This bottle unscrambling turning table is a dynamic worktable with frequency control. Its procedure: put bottles onto round turntable, then turntable rotate to poke bottles onto conveying belt, capping is began when bottles are sent into capping machine.

If your bottle/jars diameter is large, you can choose large diameter unscrambling turning table, such as 1000mm diameter , 1200mm diameter, 1500mm diameter. If your bottle/jars diameter is small, you can choose small diameter unscrambling turning table, such as 600mm diameter, 800mm diameter.

Other type cap feeding device

If your cap can not use cap elevator for unscrambling and feeding, vibrating plate feeder is available.

Production line

Auto screw capping machine can works with bottles/jars filling machine (A), and labeling machine(B) to form production lines to pack powder or granules product into bottles/jars.

Automatic Filling machine

Consist of

1. Servo motor

2. Stirring motor

3. Hopper

4. Controlling height hand-wheel

5. Touch screen

6. Workbench

7. Electric Cabinet

8. Foot pedal

General introduction

This type semi automatic auger filler can do dosing and filling work. Due to the special professional design, so it is suitable for the fluidity or low-fluidity materials, like coffee powder, wheat flour, condiment, solid drink, veterinary drugs, dextrose, pharmaceuticals, talcum powder, agriculture pesticide, dyestuff, and so on.

Main features

■ Lathing auger screw to guarantee filling accuracy.

■ PLC control and touch screen display.

■ Servo motor drives screw to guarantee stable performance.

■ Split hopper could be washed easily and change auger conveniently to apply different products range of from fine powder to granule and different weight can be packed.

■ Weight feedback and proportion track to materials, which overcomes difficulties of filling weight changes due to materials' density change.

■ Save 20 sets of formula inside the machine for later use.

■ Chinese/English language interface.

Specification

|

Model |

TP-PF-A10 |

TP-PF-A21 |

TP-PF-A22 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

11L |

25L |

50L |

|

Packing Weight |

1-50g |

1 - 500g |

10 - 5000g |

|

Weight dosing |

By auger |

By auger |

By auger |

|

Packing Accuracy |

≤ 100g, ≤±2% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

|

Filling Speed |

40–120 times per min |

40–120 times per min |

40–120 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

0.84 KW |

1.2 KW |

1.6 KW |

|

Total Weight |

90kg |

160kg |

300kg |

|

Overall Dimensions |

590×560×1070mm |

1500×760×1850mm |

2000×970×2300mm |

Automatic labeling machine

Descriptive abstract

TP-DLTB-A model labeling machine is economical, independent and easy to operate. It is equipped with automatic teaching and programming touch screen. The built-in microchip stores different job Settings, and the conversion is quick and convenient.

■ Labeling self-adhesive sticker on top, flat or big radians surface of product.

■ Products Applicable: square or flat bottle, bottle cap, electrical components etc.

■ Labels Applicable: adhesive stickers in roll.

Key features

■ Labeling speed up to 200 CPM

■ Touch Screen Control System with Job Memory

■ Simple Straight Forward Operator Controls

■ Full-set protecting device keep operation steady and reliable

■ On-Screen trouble shooting & Help Menu

■ Stainless steel Frame

■ Open Frame design, easy to adjust and change the label

■ Variable Speed with stepless motor

■ Label Count Down (for precise run of set number of labels) to Auto Shut Off

■ Automatic Labeling, work independently or connected to a production line

■ Stamping Coding Device is optional

Specifications

| Working direction | Left → Right (or Right → Left) |

| Bottle diameter | 30~100 mm |

| Label width(max) | 130 mm |

| Label length(max) | 240 mm |

| Labeling Speed | 30-200 bottles/minute |

| Conveyor speed(max) | 25m/min |

| Power source & consumption |

0.3 KW, 220v, 1 Ph, 50-60HZ(Optional) |

| Dimensions |

1600mm×1400mm×860 mm ( L × W × H ) |

| Weight | 250kg |

Application

■ Cosmetic /personal care

■ Household chemical

■ Food & beverage

■ Nutraceuticals

■ Pharmaceutial

Factory showroom

Shanghai Tops Group Co., Ltd. (www.topspacking.com) is professional manufacturer of capping machine for more than ten years in Shanghai. We specialize in the fields of designing, manufacturing, supporting and servicing a complete production line of machinery for different kinds of powder and granular products, our main target of working is to offer the products which are related to the food industry, agriculture industry, chemical industry, and pharmacy field and more. We value our customers and are dedicated to maintaining relationships to ensure continued satisfaction and create win-win relationship.

FAQ

How to find a Packing machine suitable for my product?

Tell us about your product details and packing requirements.

1. What kind of product you would like to pack?

2. The bag/sachet/pouch size of you need for the product packing ( the length, width).

3. The weigh of each pack you need.

4. You requirement for the machines and the bag style.

Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you.

In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

How can we make sure about the machine quality after placking the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality.

And also you can arrange for quality checking by yourself or by your contacts in China.

We are afraid you won't send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use Alibaba trade assurance service, guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Can you explain me the whole transaction process?

1. Sign the Contact or Proforma invoice

2. Arrange 30% deposit to our factory

3. Factory arrange production

4. Testing & detecting the machine before shipping

5. Inspected by customer or third agency through online or site test.

6. Arrange the balance payment before shipment.

Will you provides the delivery service?

Yes. Please inform us of your final destination, we will check with our shipping department to quote the shipping cost for your reference before delivery. We have our own freight forwarding company, so the freight is also more advantageous. In the UK and the United States set up our own branches, and the UK and the United States customs direct cooperation, master the first-hand resources, eliminate the information difference at home and abroad, the whole process of goods progress can realize real-time tracking. Foreign companies have their own customs brokers and trailer companies to help the consignee to quickly clear customs and deliver goods, and make sure the goods arrive safely and on time. For the goods exported to Britain and the United States, consignors can consult us if they have any questions or don't understand. We will have professional staff to give a full response.

How long does the auto capping machine lead time?

For standard model screw capping machine, the lead time is 20 days after receiving your down payment. As to customized capping machine, the lead time is about 30 days upon receiving your deposit. Such as customize motor, customize additional function, etc.

What about your company service?

We Tops Group focus on service in order to provide a optimal solution to customers including before-sales service and after-sales service. We have stock machine in showroom for making test to help customer make final decision. And we also have agent in Europe, you can make a testing in our agent site. If you place order from our Europe agent, you also can get after-sale service in your local. We always care about your capping machine running and after-sales service is always at your side to ensure everything runs perfectly with guaranteed quality and performance.

Regarding after-sales service, if you place order from Shanghai Tops Group, within one year’s warranty, if the capping machine have any problem, we will free send the parts for replacement, including express fee. After warranty, if you need any spare parts, we will give you the parts with cost price. In case of your capping machine fault happening, we will help you to deal with it in first time, to send picture/video for guidance, or live online video with our engineer for instruction.

Do you have the ability of design and propose solution?

Of course, we have professional design team and experienced engineer. For example, if your bottle/jar diameter range is large, we will design adjustable width conveyor to equip with the capping machine.

What shape bottle/jar can capping machine handle?

It is best suitable for Round and square, other irregular shapes of Glass, Plastic, PET, LDPE, HDPE Bottles, need confirm with our engineer. The bottles/jars hardness must can be clamped, or it can not screw tight.

Food industry: all kinds of food, spices bottle/jars, drink bottles.

Pharmaceuticals industry: all kinds of medical and health care products bottles/jars.

Chemical industry: all kinds of skin care and cosmetics bottles/jars.

How can i get the price?

We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.