Brief introduction

Bagged products are ubiquitous in our daily lives. Are you familiar with the process of packing these items into the bags? Apart from manual and semi-automatic filling machines, the majority of bagging operations utilize fully automatic packaging machines for efficient and automated packaging. These fully automatic bag packaging machines are capable of performing functions such as bag opening, zipper opening, filling, and heat sealing. They find extensive application in various industries including food, chemicals, pharmaceuticals, agriculture, and cosmetics.

Applicable product

The automatic bag packaging machine can pack powder products, granules products, liquid products. As long as we equip suitable filling head with the automatic bag packaging machine, it can pack various kinds of products.

Applicable bag types

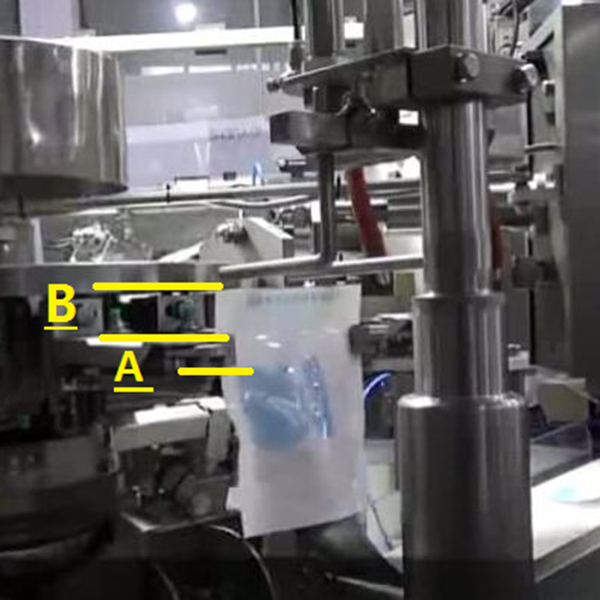

A: 3 side seal bags;

B: stand up bags;

C: zipper bags;

D: side gusset bags;

E: box bags;

F: spout bags;

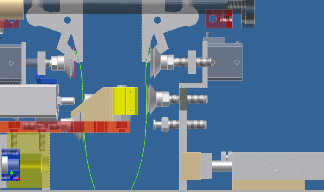

Automatic bag packing machine types

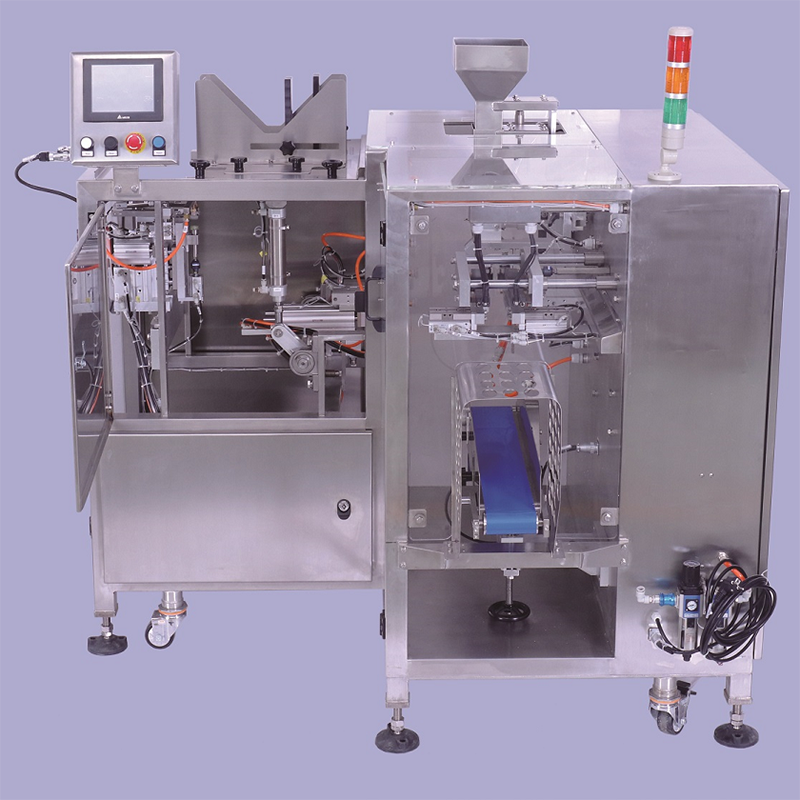

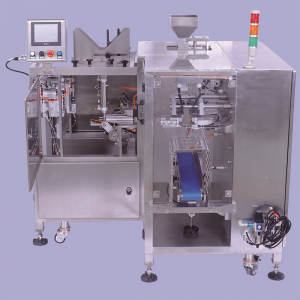

A: Single station automatic bag packaging machine

This single station packaging machine has a small footprint and it also can be called a mini packaging machine. It mainly used for small capacity user. Its packing speed is about 10 bags per minute based on 1kg packing weight.

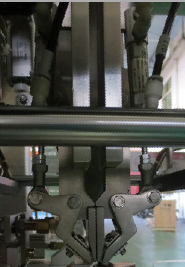

Key Feature

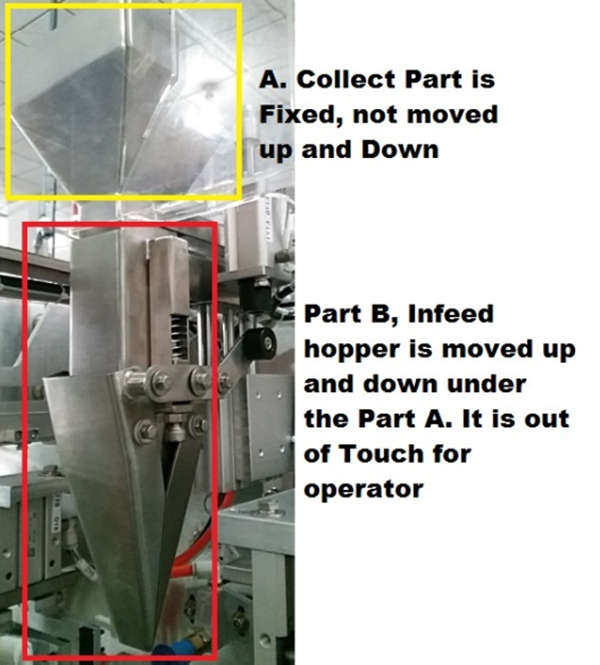

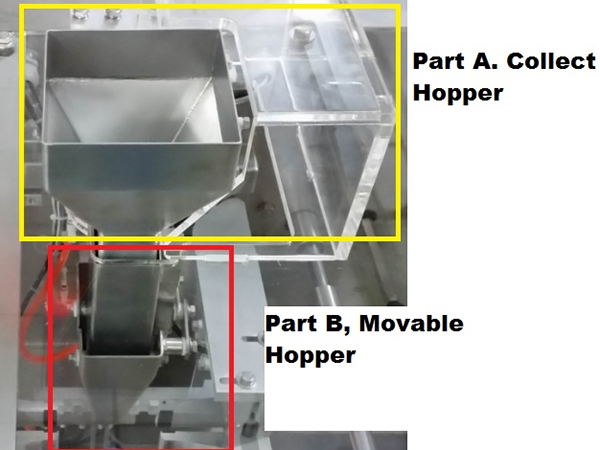

- The machine runs straight flow design makes accessibility of parts.

- It allows the operator to see the entire filling process from the front of the machine during the running. Meantime, It is easy to clean and simply open the front clear transparent doors of the machine and access all bag filling areas.

- It takes a few minutes to do the clean with only one person, it is very simple and convenient.

- Another feature is all the mechanics are located the back of the machine and the bag filling assembly is in the front. So Product will be never touched heavy duty, mechanics as they are separated. The most important is the safety protection for the operator.

- The machine are full protector which is kept the operator being out of the moving component during the machine running.

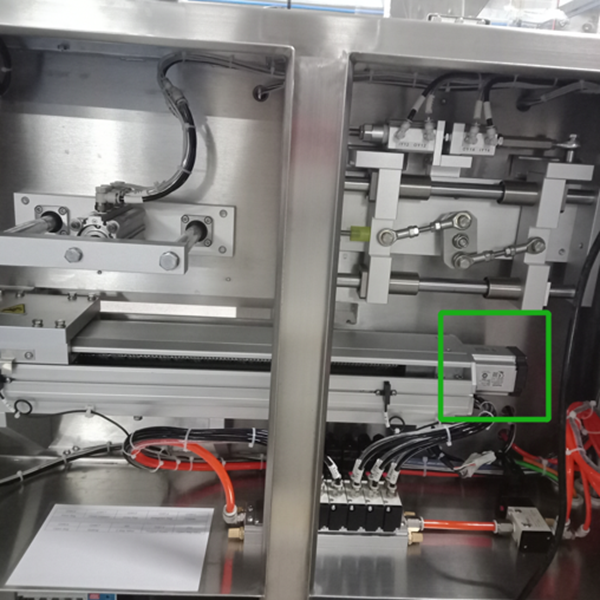

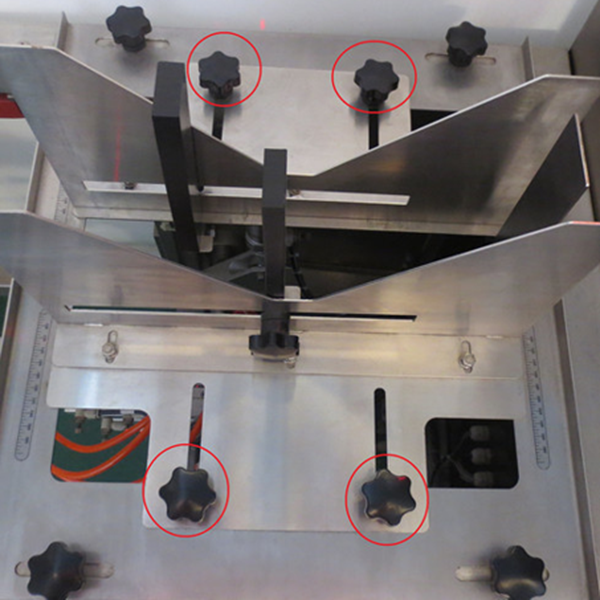

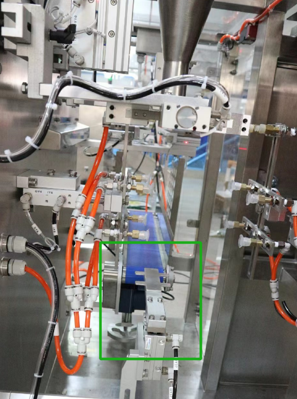

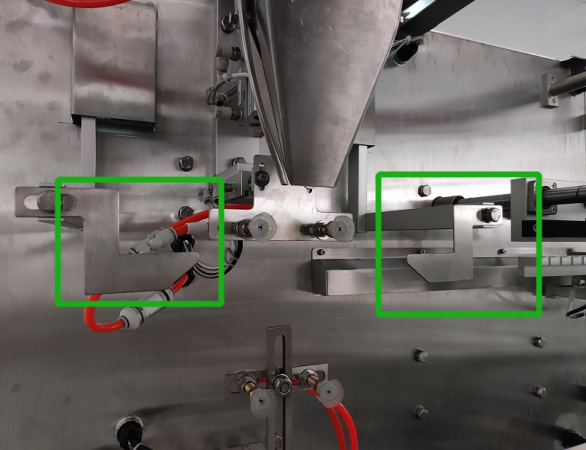

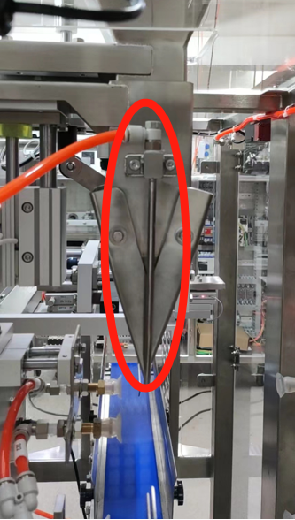

Detailed photos

Specification

| Model No. | MNP-260 |

| Bag Width | 120-260mm (can be customized) |

| Bag Length | 130-300mm (can be customized) |

| Bag Type | Stand-up bag, pillow bag,3 side seal,zipper bag, etc |

| Power Supply | 220V/50HZ Single Phase 5 Amps |

| Air Consumption | 7.0 CFM@80 PSI |

| Weight |

500kgs |

Metering mode for your choice

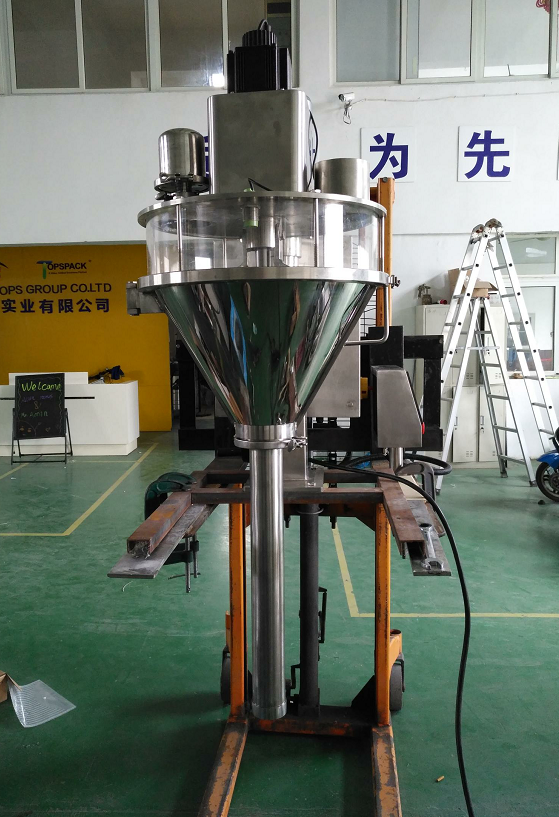

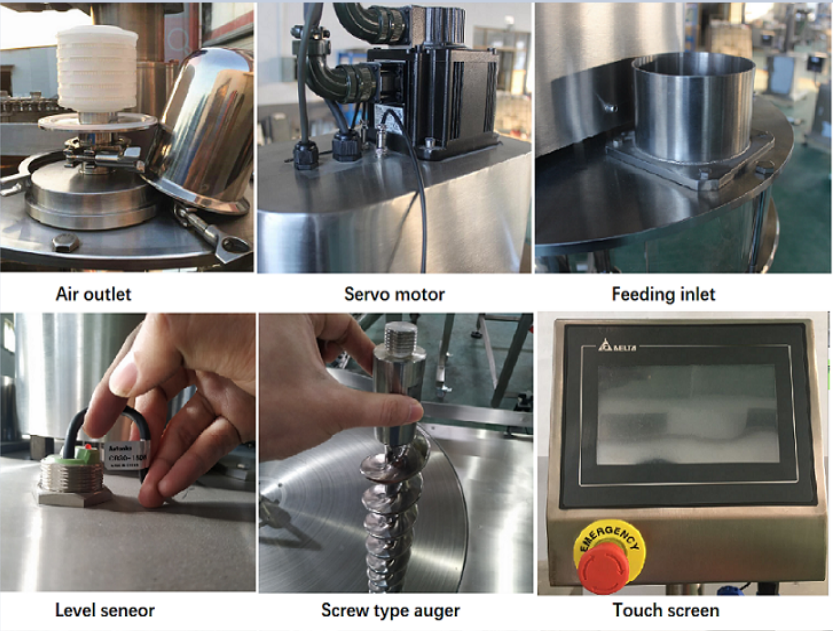

A: Auger filling head

General Description

Auger filling head can do dosing and filling work. Due to the special professional design, so it is suitable for the fluidity or low-fluidity powder materials, like coffee powder, wheat flour, condiment, solid drink, veterinary drugs, dextrose, pharmaceuticals, talcum powder, agriculture pesticide, dyestuff, and so on.

General Description

- Lathing auger screw to guarantee filling accuracy;

- Servo motor drives screw to guarantee stable performance;

- Split hopper could be washed easily and change auger conveniently to apply different products range of from fine powder to granule and different weight can be packed;

- Weight feedback and proportion track to materials, which overcomes difficulties of filling weight changes due to materials’ density change.

Specification

| Model | TP-PF-A10 | TP-PF-A11 | TP-PF-A14 |

| Control system | PLC& touch screen | ||

| Hopper | 11L | 25L | 50L |

| Packing weight | 1-50g | 1 - 500g | 10 - 5000g |

| Weight dosing | By auger | ||

| Packing accuracy | ≤ 100g, ≤±2% | ≤ 100g, ≤±2%; 100 – 500g, ≤±1% | ≤ 100g, ≤±2%; 100 – 500g,

≤±1%; ≥500g,≤±0.5% |

| Power Supply | 3P AC208-415V 50/60Hz | ||

| Total Power | 0.84 KW | 0.93 KW | 1.4 KW |

| Total Weight | 50kg | 80kg | 120kg |

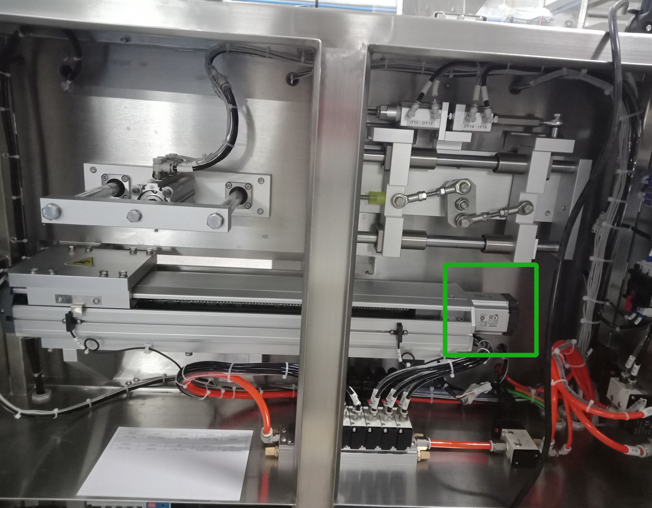

Detailed photos

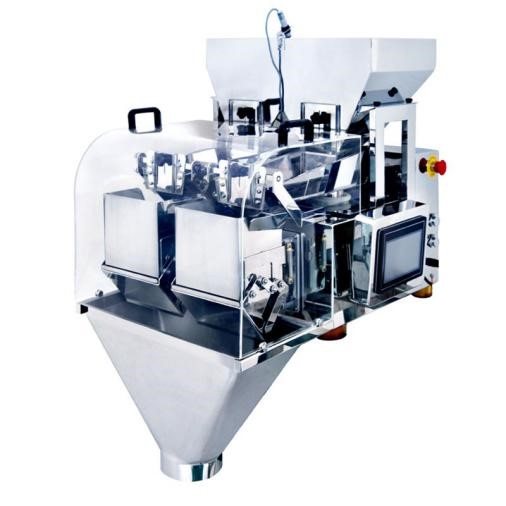

B: Linear weighing filling head

Model No. TP-AX1

Model No. TP- AX2

Model No.TP- AXM2

Model No.TP- AXM2

Model No.TP- AXM2

General Description

TP-A series Vibrating linear weigher is mainly to fill various kinds of granules product, its advantage is with high speed,high accuracy,long-term stable performance, favourable price and excellent after-sale service. It is suitable for weighing slice ,roll or ragular shape products such as sugar ,salt ,seed ,rice , seasame , glutamate ,coffeebean and season powder etc.

Main features

Sanitation with 304S/S construction ;

Rigid design for vibrator and feed pan make feeding strictly correct ;

Quick release design for all the contact parts

Grand new modular control system .

Adopt stepless vibrating feeding system to make products flow more fluently .

Make mix different products weighing at one discharge .

Parameter can be freely adjusted according to production .

Specifications

| Model | TP-AX1 | TP-AX2 | TP-AXM2 | TP-AX4 | TP-AXS4 |

|

Weighing Range |

20-1000g |

50-3000g |

1000-12000g |

50-2000g |

5-300g |

|

Accuracy |

X(1) |

X(1) |

X(1) |

X(1) |

X(1) |

|

Max Speed |

10-15P/M |

30P/M |

25P/M |

55P/M |

70P/M |

|

Hopper Volume |

4.5L |

4.5L |

15L |

3L |

0.5L |

|

Parameters Press No. |

20 |

20 |

20 |

20 |

20 |

|

Max Mixing Products |

1 |

2 |

2 |

4 |

4 |

|

Power |

700W |

1200W |

1200W |

1200W |

1200W |

|

Power Requirement |

220V/50/60Hz/5A |

220V/50/60Hz/6A |

220V/50/60Hz/6A |

220V/50/60Hz/6A |

220V/50/60Hz/6A |

|

Packing Dimension(mm) |

860(L)*570(W)*920(H) |

920(L)*800(W)*890(H) |

1215(L)*1160(W)*1020(H) |

1080(L)*1030(W)*820(H) |

820(L)*800(W)*700(H) |

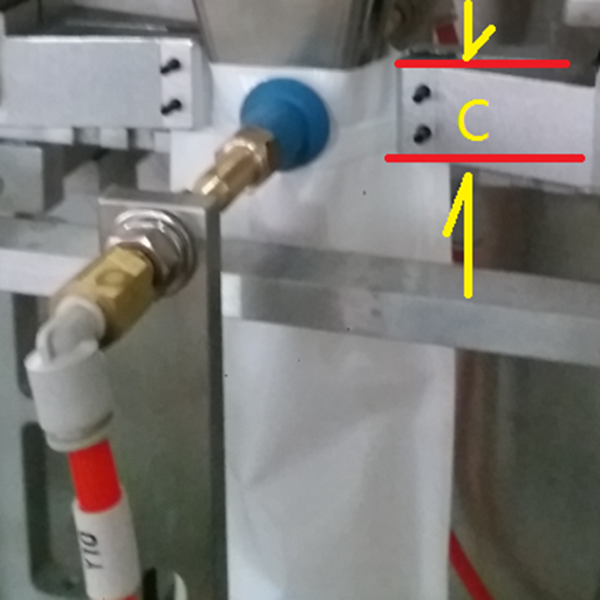

C: Piston pump filling head

General Description

Piston pump filling head has a simpler and more reasonable structure, high precision and easier operation. It is suitable for liquid product’s filling and dosing. It apply to medicine, daily chemical, food, pesticide and special industries. It is an ideal equipment for filling high viscosity fluids and flowing liquids. The design is reasonable, the model is small, and the operation is convenient. The pneumatic parts all use the pneumatic components of Taiwan AirTac. The parts in contact with materials are made of 316L stainless steel and ceramics, which meets GMP requirements. There is a handle for adjusting the filling volume, the filling speed can be adjusted arbitrarily, and the filling accuracy is high. The filling head adopts anti-drip and anti-drawing filling device

Specifications

| Model | TP-LF-12 | TP-LF-25 | TP-LF-50 | TP-LF-100 | TP-LF-1000 |

| Filling volume | 1-12ml | 2-25ml | 5-50ml | 10-100ml | 100-1000ml |

| Air pressure |

0.4-0.6Mpa |

||||

| Power |

AC 220v 50/60hz 50W |

||||

| Filling speed |

0-30 times per minute |

||||

| Material | Touch product parts SS316 material, others SS304 material | ||||

Pre-sale service

1. Support product customization, any requirements you need can be customized according to your requirements.

2. Sample test on our counting line.

3. Provide business consulting and technical support, as well as a free professional packaging solution

4. Make a machine layout for customers based on customers' factories.

After-sales service

1. Manual book.

2. Videos of installation, adjusting, setting, and maintenance, are available for you.

3. Online support, or face-to-face online communications, are available.

4. The engineer overseas services, are available. The tickets, visa, traffic, living, and eating, are for customers.

5. During the warranty year, without human-being broken, we will replace a new one for you.

FAQ

Q: Where is your factory? Can I visit your factory?

A: Our factory is located in Shanghai. We warmly welcome you to visit our factory if you have a travel plan.

Q: How can I know your machine is suitable for you product?

A: If possible, you can send us samples and we will test on machines.So can we will take videos and pictures for you. We can also show you on-line by video chatting.

Q: How can I trust you for the first-time business?

A: You can check our business license and certificates. And we suggest using Alibaba Trade Assurance Service for all transactions to protect your money rights and interests.

Q: How about the after service and guarantee period?

A: We offer one years warranty since the arrival of the machine. Technical support is available 24/7. We have professional after-sale team with experienced technician to do the best after service to assure the machine whole life usage.

Q:How to contact you?

A: Please leave messages and click "send" to send us inquiries.

Q: Does the machine power voltage meet buyer’s factory power source?

A: We can customize the voltage for your machine according to your requirements.

Q: What’s the payment terms?

A: 30% deposit and 70% balance payment before shipment.

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we can offer both OEM Services and technical support. Welcome to start your OEM business.

Q: What are your Installation Services?

A: Installation Services are available with all new machine purchases. We will provide the user manual and videos to support installing, debugging, operation of the machine, which will indicate to you how to use this machine well.

Q: What info will be needed to confirm machine models?

A: 1.The material status.

2. Filling range.

3. Filling speed.

4. Requirements for the production process.