General Description

GRINDING MACHINE

TP-GM Series

Applied as supporting equipment before fine crushing process in such trades as pharmaceutical, chemical and foodstuff etc. This machine is a new generation coarse crushing equipment combining and dust collection as a whole.

Product Overview

Application

Grinder is mainly applied to food (red dates, sugar, rice, corn, starch, oats, flour, beans, peas, lentils and spices, cocoa powder, potato powder, coffee, salt, milk, onion,dehydrated vegetables, glucose , oat hull, husk, herbal flavors and fragrances),chemical (polyethylene, PVC, polystyrene, polyvinyl alcohol, limestone, gypsum, paints, pigments) grinding, especially for oily, viscous material.

Features

● Designed according to GMP standard and wholly made of stainless steel.

● This machine has no flying dust during production, and can improve the utilization rate of material and reduce the cost of enterprise, and reach the international advanced level.

● Grinding machine inside adopts high-speed rotary grinding wheel cutter, machine inside is with large air volume, not easy to get heating.

● It has advantage of stable running, easy d is assembly and cleaning, low noise, good effect for the smash.

Technical Configuration

Work Principle

● The raw material is sent into the machine hopper by the feeder conveyor, then leaks into the crashing cabin.

● The leather belt driven by motor spurs the motional hammers whirling in a high speed, the hammers chafe, collide with the immovable fluted disc in a high speed, then the raw material is ground.

● The ground powder will leaks from the screen stencil, gets out from the discharge hole, stored inside the bag.

Technical Parameters

| Order | TP-GM-20B | TP-GM-30B | TP-GM-40B | TP-GM-60B |

| Capacity (kg / h) | 60-100 | 100-300 | 160-800 | 500-1500 |

| Feed size (mm) | <6 | <10 | <12 | <15 |

| Grinding fineness

(mesh) |

3-120 | |||

| Spindle speed

(r / min) |

4500 | 3800 | 3400 | 2800 |

| Motor Power (k w) | 4 | 5.5 | 7.5 | 11 |

| Weight (kg) | 150 | 250 | 380 | 550 |

| Dimensions (mm)

(L × W × H) |

960×750× 1750 | 1000×900× 1680 | 1200×650× 1550 | 1350×750× 1680 |

Details

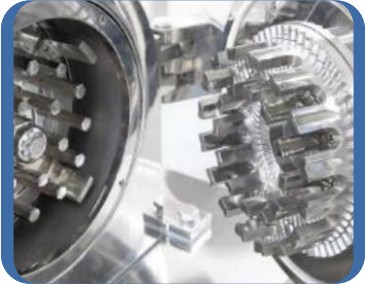

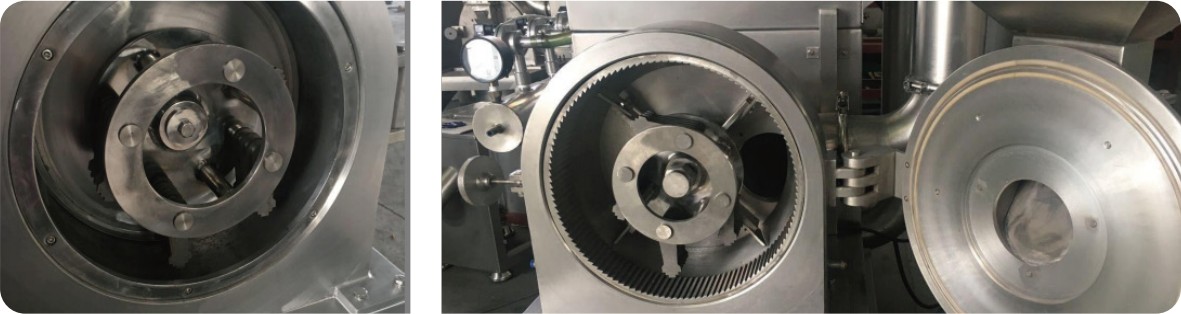

Inside Mill Chamber

Disc Type: This is toothed disc Type, Relatively low noise, more suitable materials,more common use.

It makes use of the high-speed relativemovement of the movable fluted disc and the fixed fluted disc to crush the materials through the comprehensive effect of striking and friction of the fluted disc as well as the mutual striking of the material.

Also we could change turbo, hammer or any other type.

Hammer Type: Suitable for crushing hard material with low fineness requirement.

Turbo Type: Stable wind force, uniform crushing, good fineness; Suitable for crushing materials with high humidity or a small amount of sugar or oil.

Cutter Type: It's is suitable for grinding,aterial like chili pepper, maize which has fiber peel.

Screen Mesh

The crushed materials can be discharged directly from the grinding chamber of the host machine and the desired powder size can be obtained by installing screens with different size.

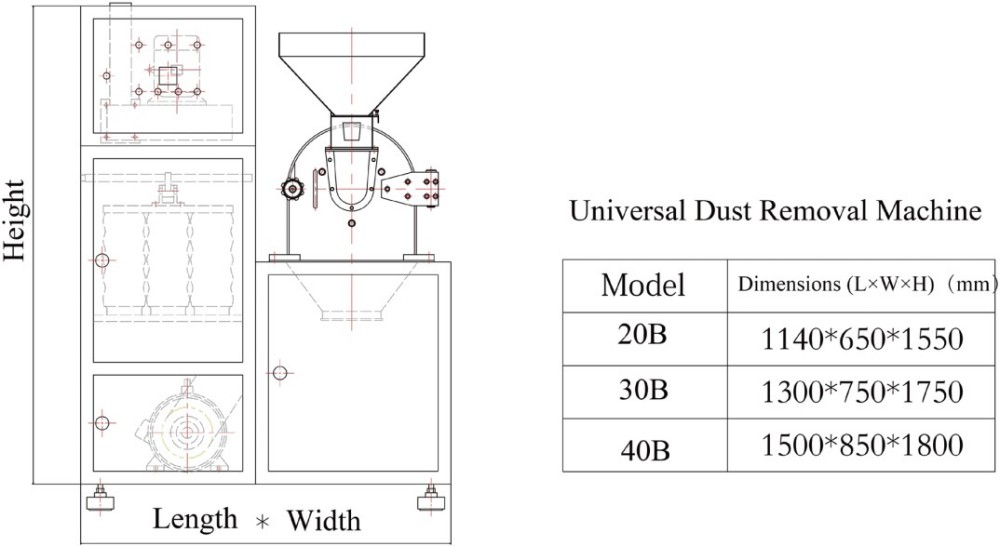

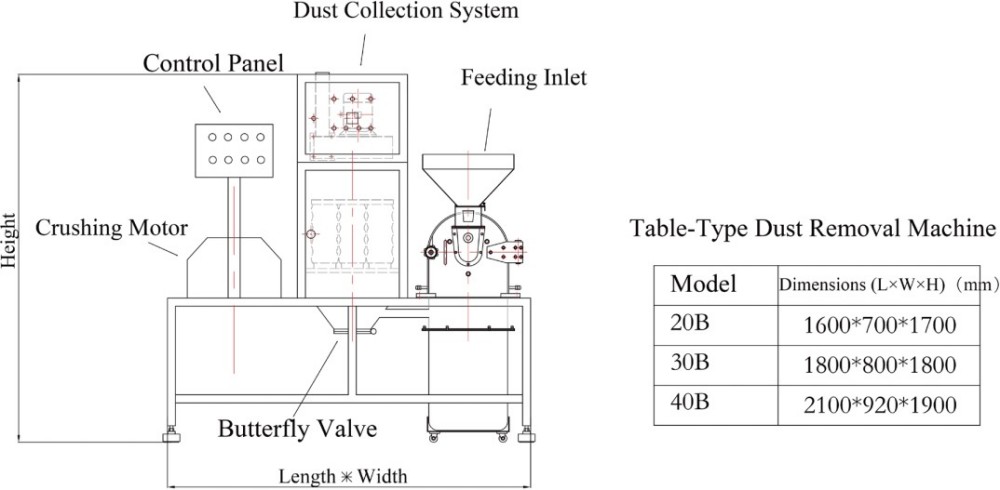

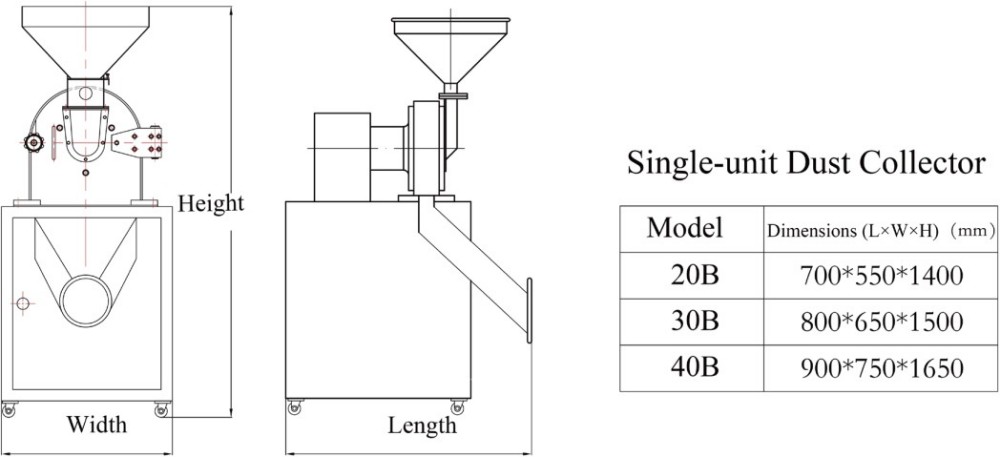

Dust Collector

The dust collecting bag can effectively collect the fine powder in the air current so as to meet the requirements for cleanness and environmental protection in waste gas discharge.

Water Cooling Device

It is easy to generate heat for the high speed operation of the crusher, more materials can achieve good crushing effect after adding water cooling device.

Collecting Barrel

It is easy to move with casters.

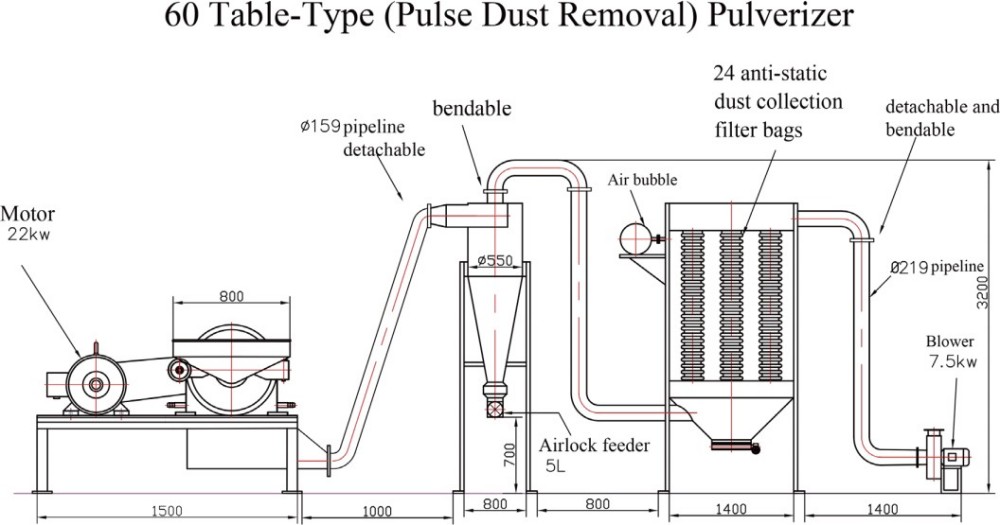

Structure & Drawing