General Description

Double Cone Mixing Machine

TP-W Series

A double cone mixer is a type of industrial mixing equipment commonly used in various industries for blending dry powders and granules. Its mixing drum is composed of two interconnected cones. The double cone design allows for efficient mixing and blending of materials. It's widely used in food,chemical

and pharmacy industry.

Application

This double cone shape mixer machine is commonly used in dry solid blending materials and used in the following application:

• Pharmaceuticals: mixing prior to powders and granules

• Chemicals: metallic powder mixtures, pesticides and herbicides and many more

• Food processing: cereals, coffee mixes, dairy powders, milk powder and many more

• Construction: steel preblends and etc.

• Plastics : mixing of master batches, mixing of pellets, plastic powders and many more

Working Principle

The double cone mixer/blender is primarily utilized for the thorough dry mixing of free-flowing solids. The materials are introduced into the mixing chamber through a quick-open feed port, either manually or via a vacuum conveyor.

Through the 360-degree rotation of the mixing chamber, the materials are thoroughly blended to achieve a high degree of homogeneity. Typical cycle times usually fall within the range of 10 minutes. You can adjust the mixing time to your desired duration using the control panel, depending on the liquidity of your product.

Parameters

| Item | TP-W200 | TP-W300 | TP-W500 | TP-W1000 | TP-W1500 | TP-W2000 |

| Total Volume | 200L | 300L | 500L | 1000L | 1500L | 2000L |

| Effective

Loading Rate |

40%-60% | |||||

| Power | 1.5kw | 2.2kw | 3kw | 4kw | 5.5kw | 7kw |

| Tank Rotate Speed | 12 r/min | |||||

| Mixing Time | 4-8mins | 6-10mins | 10-15mins | 10-15mins | 15-20mins | 15-20mins |

| Length | 1400mm | 1700mm | 1900mm | 2700mm | 2900mm | 3100mm |

| Width | 800mm | 800mm | 800mm | 1500mm | 1500mm | 1900mm |

| Height | 1850mm | 1850mm | 1940mm | 2370mm | 2500mm | 3500mm |

| Weight | 280kg | 310kg | 550kg | 810kg | 980kg | 1500kg |

STANDARD CONFIGURATION

| No. | Item | Brand |

| 1 | Motor | Zik |

| 2 | Relay | CHNT |

| 3 | Contactor | Schneider |

| 4 | Bearing | NSK |

| 5 | Discharge Valve | Butterfly Valve |

Details

Safety fence.

The machine features a safety fence, and it automatically stops when the safety fence is opened, ensuring the safety of the operator.

A variety of safety fence structures are available for you to choose from.

Openable gate

Fence rail

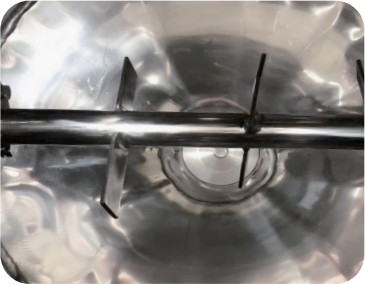

Inside of the tank

The inner surface is fully welded and polished, making it easy to clean and ensuring hygiene. There are no dead angles during discharging.

It features an intensifier bar that enhances mixing efficiency.The tank's interior is constructed entirely of stainless steel 304, ensuring the highest quality material for all components.

You can choose from a variety of stirring structures according to your preferences.

Rotary scrapers

Fixed scraper

Rotary bars

Electric control panel

The inclusion of a time relay allows for adjustable mixing times based on the material and mixing process requirements.

An inching button is incorporated to rotate the tank to the optimal charging or discharging position, facilitating material feeding and discharge.

Additionally, the machine is equipped with a heating protection feature to prevent motor damage caused by overloads.

Charging Port

The feeding inlet is equipped with a movable cover that can be easily operated by pressing the lever.

It is constructed using stainless steel material, ensuring durability and hygiene.

A range of structures are available for you to choose from.

Movable cover

Manual butterfly valve

Pneumatic butterfly valve