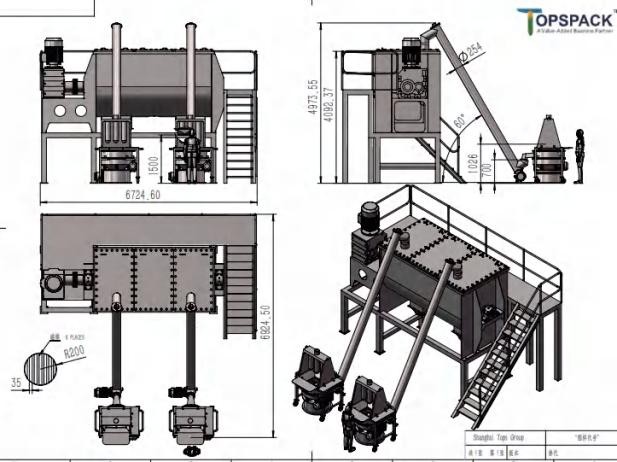

General Description

Large model Double Ribbon Mixer

TDPM Series

The horizontal ribbon mixer is extensively employed in various industries such as chemicals, pharmaceuticals, food processing, and construction. It serves the purpose of blending powder with powder, powder with liquid, and powder with granules. Driven by a motor, the double ribbon agitator facilitates efficient convective mixing of materials in a short period of time.

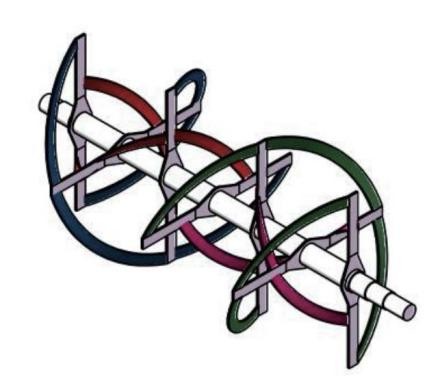

Working Principle

The outer ribbon guides the material from both sides towards the center

The inner ribbon propels the material from the center towards both sides

MAIN FEATURES

● At the bottom of the tank, there is a center-mounted flap dome valve (available in both pneumatic and manual control options). The valve features an arc design that ensures there is no material accumulation and eliminates any potential dead angles during the mixing process. The dependable and consistent sealing mechanism prevents leakage during the frequent opening and closing of the valve.

● The dual ribbons of the mixer facilitate a faster and more uniform mixing of the materials in a shorter period of time.

● The entire machine is constructed from stainless steel 304 material, featuring a

fully mirror-polished interior within the mixing tank, as well as the ribbon and shaft.

● Equipped with a safety switch, safety grid, and wheels, ensuring safe and convenient usage.

● Guaranteed zero shaft leakage with Teflon rope seal from Bergman (Germany) and a distinctive design.

Specification

|

Model |

TDPM 2000 | TDPM 3000 | TDPM 4000 | TDPM 5000 | TDPM 8000 | TDPM 10000 | ||

| Effective Volume (L) | 2000 | 3000 | 4000 | 5000 | 8000 | 10000 | ||

| Fully Volume(L) | 2500 | 3750 | 5000 | 6250 | 10000 | 12500 | ||

| Total Weight(KG) | 1600 | 2500 | 3200 | 4000 | 8000 | 9500 | ||

| Total Power(KW) | 22 | 30 | 45 | 55 | 90 | 110 | ||

| Total Length(mm) | 3340 | 4000 | 4152 | 4909 | 5658 | 5588 | ||

| Total Width(mm) | 1335 | 1370 | 1640 | 1760 | 1869 | 1768 | ||

| Total Hight(mm) | 1925 | 2790 | 2536 | 2723 | 3108 | 4501 | ||

| Barrel Lehgth(mm) | 1900 | 2550 | 2524 | 2850 | 3500 | 3500 | ||

| Barrel Width(mm) | 1212 | 1212 | 1560 | 1500 | 1680 | 1608 | ||

| Barrel Hight(mm) | 1294 | 1356 | 1750 | 1800 | 1904 | 2010 | ||

| Radius of Barrel(mm) | 606 | 606 | 698 | 750 | 804 | 805 | ||

| Power Supply | ||||||||

| Shaft Thickness(mm) | 102 | 133 | 142 | 151 | 160 | 160 | ||

| Tank Body Thickness (mm) | 5 | 6 | 6 | 6 | 8 | 8 | ||

| Side Body Thickness (mm) | 12 | 14 | 14 | 14 | 14 | 16 | ||

| Ribbon Thickness (mm) | 12 | 14 | 14 | 14 | 14 | 16 | ||

| Motor Power(KW) | 22 | 30 | 45 | 55 | 90 | 110 | ||

| Max Motor Speed(rpm) | 30 | 30 | 28 | 28 | 18 | 18

|

||

Note:The specifications can be customized based on the distinctive features of different products.

Accessories List

| No. | Name | Brand |

| 1 | Stainless steel | China |

| 2 | Circuit breaker | Schneider |

| 3 | Emergency switch | CHINT |

| 4 | Switch | GELEI |

| 5 | Contactor | Schneider |

| 6 | Assist contactor | Schneider |

| 7 | Heat relay | CHINT |

| 8 | Relay | CHINT |

| 9 | Timer relay | CHINT |

| 10 | Motor & Reducer | Zik |

| 11 | Oil water separator | Airtac |

| 12 | Electromagnetic valve | Airtac |

| 13 | Cylinder | Airtac |

| 14 | Packing | Burgmann |

| 15 | Svenska Kullager-Fabriken | NSK |

| 16 | VFD | QMA |

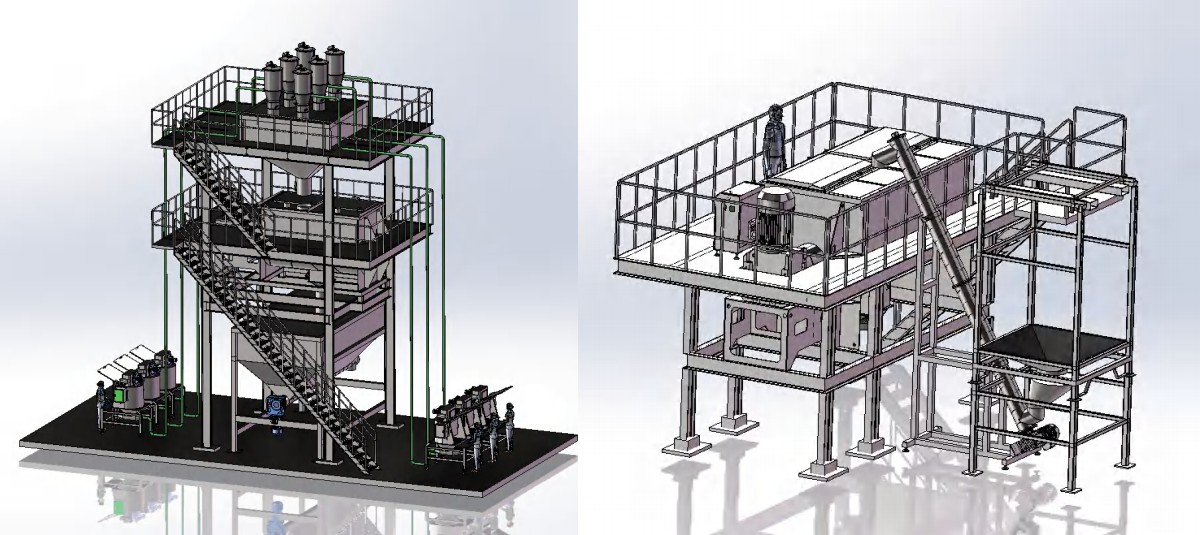

PARTS PHOTOS

A: Independent electrical cabinet and control panel;

B: Full welded and mirror polished double ribbon;

C: Gearbox directly drives the mixing shaft by a coupling and chain;

Detailed Photos

All components are interconnected through complete welding.

No leftover powder and easy cleaning after the mixing process.

The slow-rising design ensures the longevity of the hydraulic stay bar and prevents operators from being injured by a falling cover.

The safety grid keeps the operator away from the rotating ribbons and simplifies the process of manual loading.

An interlock mechanism ensures worker safety during ribbon rotation. The mixer automatically halts operation when the cover is opened.

Our patented shaft sealing design,featuring the Burgan packing gland from Germany, guarantees a leak-free operation.

A slightly concave flap at the bottom center of the tank ensures effective sealing and eliminates any dead angles during the mixing process.

Cases