Company Profile

Shanghai Tops Group Co., Ltd., an innovative mixer and packing machine manufacture with over 20 patented technologies. Our machines hold CE and ROHS certificates, and comply with UL and CAS standards.

We deeply understand customer needs and continuously update our designs, focusing on providing the most suitable and professional packaging systems. With a customer base spanning over 150 countries and regions, we are familiar with and continuously study the international market in our industry, dedicated to delivering excellent user experiences to our customers. For distributor clients, we provide industry-leading information, OEM support, and personalized designs, offering the strongest support for your continuous progress.

Choose to collaborate with us, and you will join a passionate and knowledgeable team to achieve success in the field of packaging systems. Contact us to learn more about our patented technologies and innovative products.

Application

Features

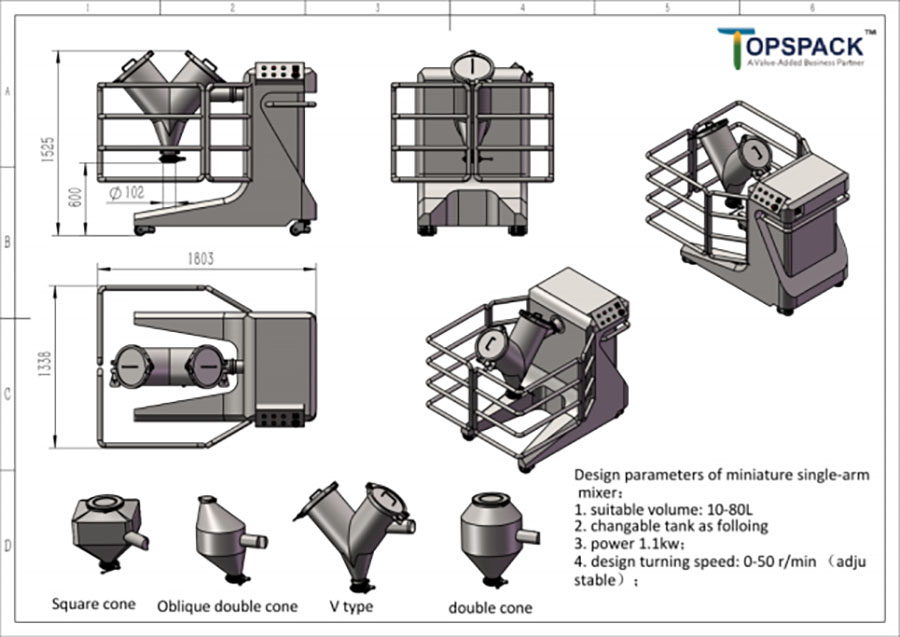

● Adaptablity and flexibility. A single-arm mixer with the choice to swap between tank types (V mixer, double cone.square cone, or oblique double cone) for a wide range of mixing needs.

● Easy cleaning and maintenance. The tanks are designed with an ease of cleaning and maintenance in mind. To easet horough cleaning and prevent material residue, it must be considered to carefully check these features such as removable parts, access panels and smooth, crevice-free surfaces.

● Documentation and Training: Provide a clear documentation and training materials to users to help them through the proper way on operation, tank switching processes, and mixer maintenance. This will ensure that the equipment isused safely and more effectively.

● Motor Power and Speed: Make sure that the motor driving the mixing arm is large and powerful enough to handle the various tank types. Contemplate the various load requirements and desired mixing speeds within each tank type.

Technical Specifications

| Single-arm Mixer | Small Size Lab Mixer | Tabletop Lab V Mixer | |

| Volume | 30-80L | 10-30L | 1-10L |

| Power | 1.1Kw | 0.75Kw | 0.4Kw |

| Speed | 0-50r/min(adjustable) | 0-35r/min | 0-24r/min(adjustable) |

| Capacity | 40%-60% | ||

| Changeable Tank |  |

||

Detailed Photos

1. The properties of each tank type

(V shape, double cone, square cone, or oblique doublcone) influence mixing performance. Within each tank type, designs the tanks tooptimize material circulation and blending. Tank dimensions, angles, and surface treatments should a be considered to enable efficient mixing and minimize material stagnation or buildup.

2. Material inlet and outlet

• The feeding inlet has movable cover through pressing the lever it is easy to operate.

• Edible silicone rubber sealing strip, good sealing performance, no pollution.

• Made of stainless steel.

• For each tank type, it designs the tanks with correct positioned and sized material inlets and outputs. lt guarantees efficient material loading and unloading, considering the individual requirements of the materials being mixed as well as the required flow patterns.

• Butterfly valve discharge.

3. Control System Integration

It considers of combining the mixer with a controlling system that is capable of handling tank switching. This would include automating the tank swapping mechanism and adjusting mixing settings based on the tank type.

4. Compatibility of Mixing Arms

lt ensures that the single-arm mixing mechanism is compatible with all tank types. The mixing arm's length,form, and connection mechanism allow for smooth operation and successful mixing within each tank type.

5. Safety Measures

This includes such as emergency stop buttons, safety guards, and interlocks should be encompassed to ensure operator safety during tank switching and operation.

Safety interlock: Mixer stops automatically when doors open.

6. Fuma Wheel

Makes machine stand stably and can be moved easily.

7. Easy to take down and assemble

Replacing and assembling the tank is convenient and easy and can be done by one person.

8. Full Welding and Polished inside and outside

Easy to clean.

Drawing

CERTIFICATES