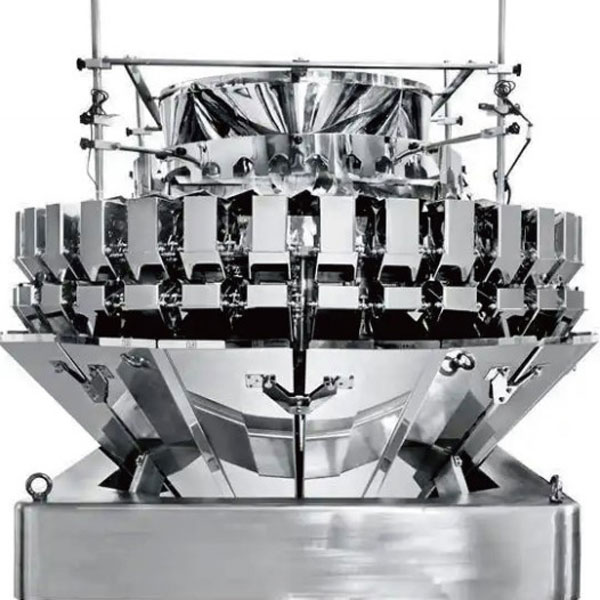

General Description

MULTIHEAD WEIGHER

TP-A Series

The Multi-heads Weigher offers advantages such as high speed, high accuracy, long-term stable performance, favorable pricing, and excellent after-sales service. It is suitable for weighing sliced, rolled, or regularly shaped products, including sugar, salt, seeds, rice, sesame, glutamate, coffee beans, seasoning powders, and more.

Model No. TP-A10

Model No. TP- A12

Model No.TP- A14

Model No. TP-A16

Model No. TP-A20

Model No. TP-A24

Model No. TP-A32

Product Overview

Application

Features

● Equipped with a high-precision, high-accuracy load cell from a renowned brand, offering a resolution of up to two decimal places.

● Program recovery function minimizes operational errors and supports multi- segment weight calibration.

● Automatic pause function when no product is detected, improving weighing stability and accuracy.

● Stores up to 100 programs to accommodate various weighing needs, with a user -friendly help menu for easy operation.

● Independent adjustment of linear amplitude during operation.

● Multiple language options available for global markets.

● Hygienic 304 stainless steel construction ensures easy cleaning and durability.

● Rigid design for the vibrator and feed pan ensures precise feeding.

● Quick-release design for all contact parts enables easy maintenance.

● Brand-new modular control system for enhanced performance.

● Stepless vibrating feeding system ensures smooth product flow.

● Capable of mixing different products and weighing them in a single discharge.

● Fully adjustable parameters to suit production requirements.

Technical Configuration

Specification

| Model | TP-A10 | TP-A12 | TP-A14 | TP-A16 | TP-A20 | TP-A24 | TP-A32 |

| Heads | 10 | 12 | 14 | 16 | 20 | 24 | 32 |

| Weighing range | 10-1000g | 10-30PCS | 10-1500g | 2-200g | 20-2000g /10-1000g | 5-240g | 5-240g |

| Accuracy | X(0.5) | ||||||

| Max speed | 65P/M | 30P/M | 120 P/M | 180 P/M | 65P/M/120P/M | 60P/M(Mixing of 4 materials) | 60x4P/M(Mixing of 4 materials) |

| Hopper capacity | 1.6/2.5L | 2.5L | 1.6L/2.5L | 0.5L | 1.6L | 0.5L | 0.5L |

| Control panel | 7-inch touch screen | 10.1-inch touch screen | 10.4-inchtouch screen | 10.1-inchtouch screen | |||

| Powerrequirement | 220V/1000W/50/60Hz/10A | 220V/1500W/50/ 60Hz/10A | 220V/2000W/50/ 60Hz/16A | 220V/1500W/50/ 60Hz/10A | 220V/2500W/50/ 60Hz/15A | ||

| Packingdimension (mm) | 1620(L)x1100 (W)x1110(H) | 1700(L)x1100 (W)x1130(H) | 1700(L)x1080 (W)x1210(H) | 1250(L)×1070 (W)x960(H) | 1700(L)x1450 (W)x1450(H) | 1800(L)x1250 (W)x1110(H) | 2100(L)x1480 (W)x1130(H) |

| Gross weight | 380kg | 470kg | 500kg | 300kg | 850kg | 440kg | 500kg |

Configuration

| Order | Item | Brand |

| 1 | Touch screen | Shanghai Kinco |

| 2 | Sensor | Taiwan Fotek |

| 3 | Power switch | Zhejiang Hengfu |

| 4 | Mainboard | Self made |

| 5 | Module board | Self made |

| 6 | Load cell | Germany HBM |

| 7 | Hopper bearing sleeve | Germany IGUS |

| 8 | Circuit breaker | Zhejiang Delixi |

Details

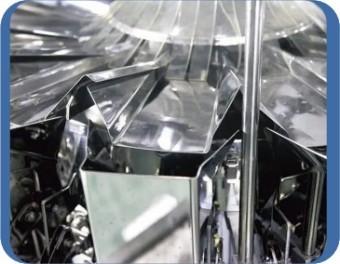

| SS304/316 stainless steel and | mirror polishing |

| for superior sanitation. |

Uniquely designed counting software with a no- divider discharge chute to effectively prevent blockage.

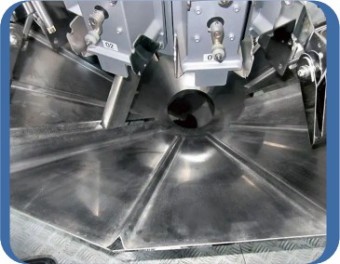

Equipped with a specially engineered central cone, the rotary top cone evenly distributes products into each linear feeder pan. are easy to clean) can be disassembled quickly and cleaned conveniently.

Load cell detection beneath the top cone ensures a smooth and consistent feeding process from the conveyor, preventing blockages and maintaining optimal material flow.

17 language options and an easy-to-use HMI. Specifications can be freely adjusted according to production requirements.

The weighing-based material detection system enables precise control over feeding time and material thickness, ensuring optimal weighing accuracy.

Structure & Drawing

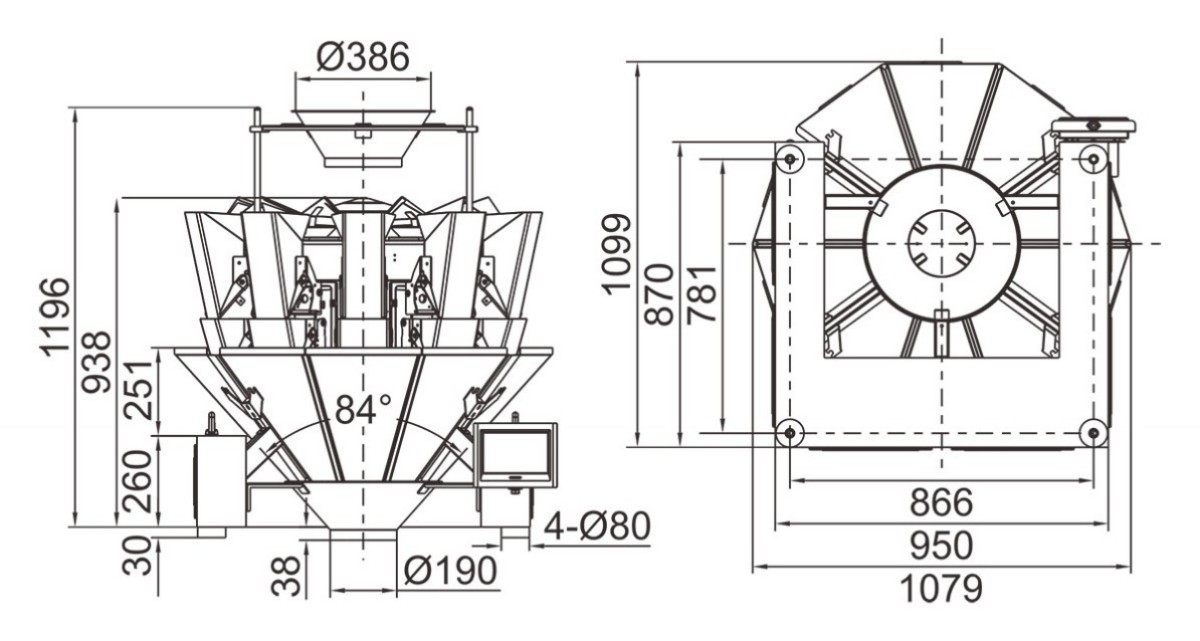

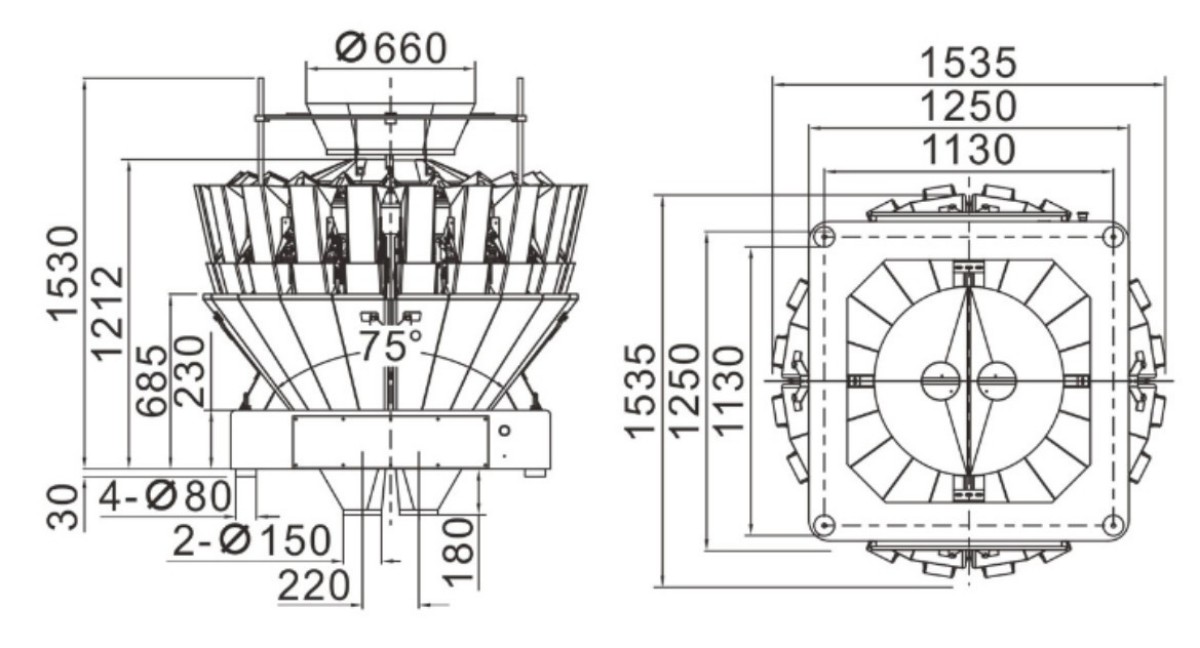

Model No. TP- A10

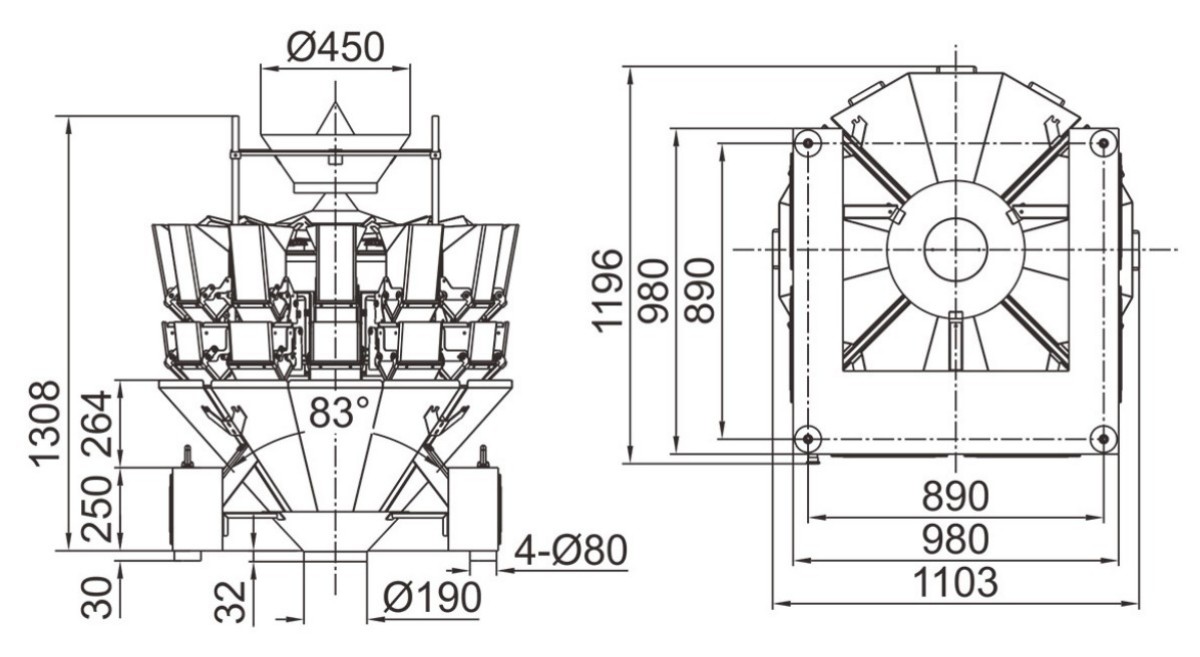

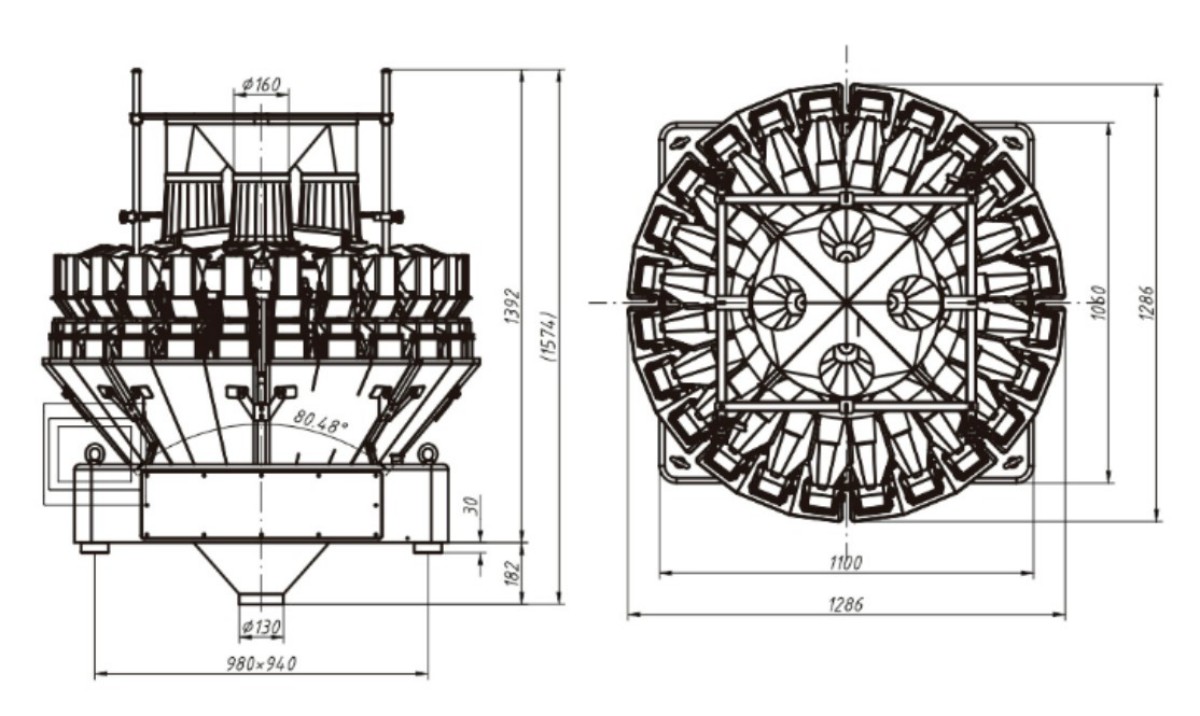

Model No. TP- A12

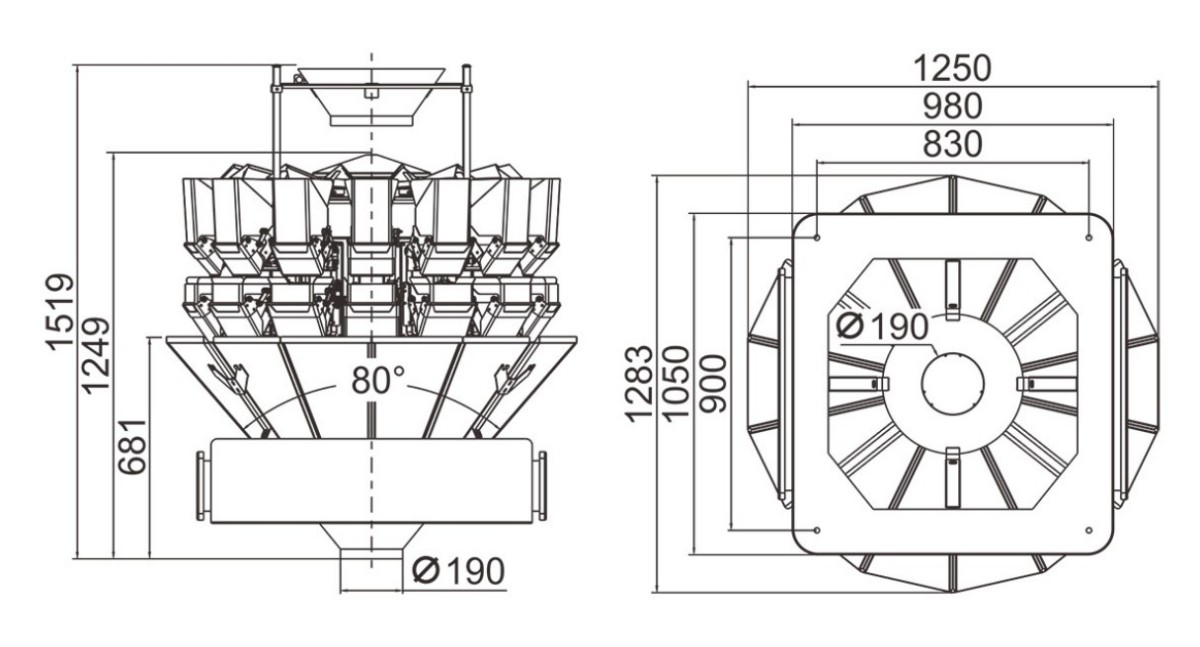

Model No. TP- A14

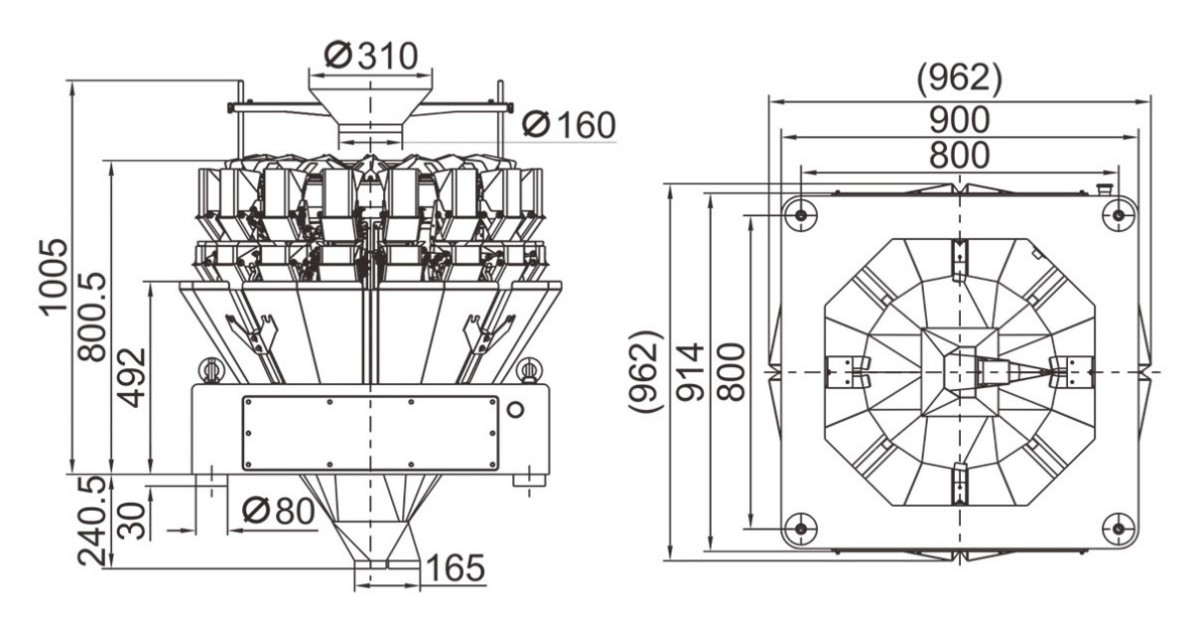

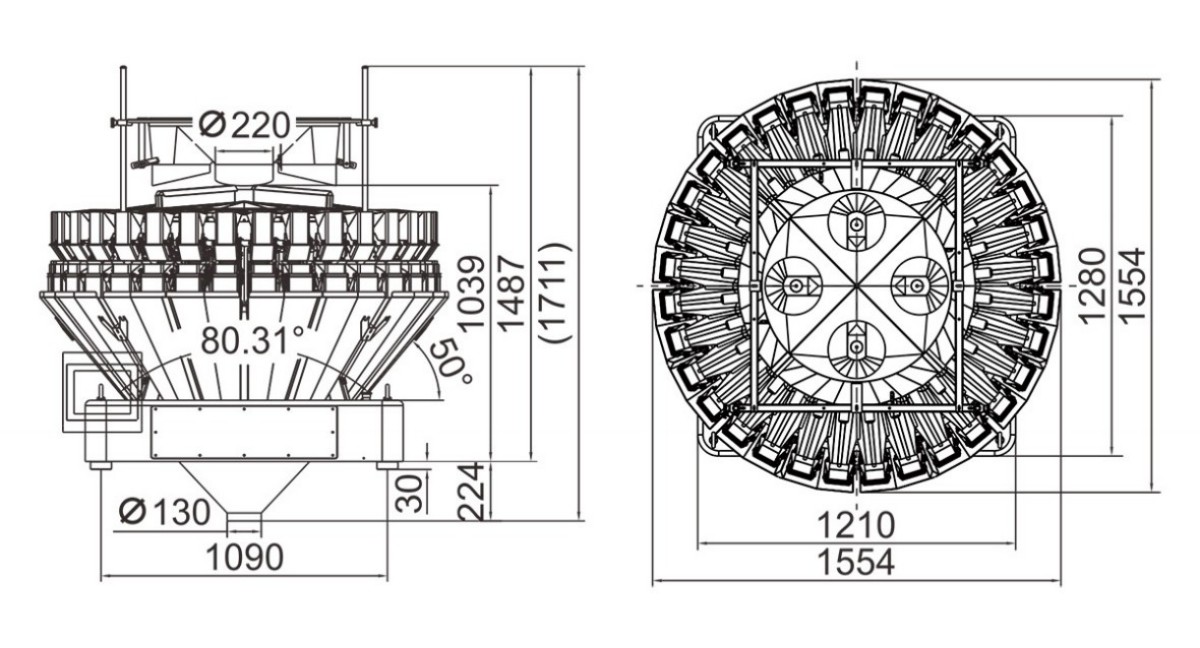

Model No. TP- A16

Model No. TP- A20

Model No. TP- A24

Model No. TP-A32