The powder mixer has different types and functions. Each type is used for mixing different materials such as powder, powder with liquid, granular products, and solid materials.

Most industries that use powder mixer are chemical, pharmaceutical, food and agricultural industries etc. It is proven to mix materials according to your desired mixture in less than a short time. These are all made of stainless-steel materials. All connection parts are entirely welded and mirror polished. There is no dead angle when the mixture is formed. It is simple to clean and operate as well.

√High quality √safe to operate √effective and efficient

√easy to operate √satisfactory results

V-Shaped Mixer

It has a plexiglass door, and it is composed of a work chamber and two cylinders that form a "V" shape. For the mixing of powder and granules, as well as the mixing of materials with a low mixing degree and a short mixing time, the machine has good flowability of materials.

High consistency, low cost, and no material storage during the mixing process

Double Cone Mixer

Its main use is intimate dry mixing of free-flowing solids. Materials are manually or by vacuum conveyor fed into the mixing chamber via a quick-open feed port. Materials are completely mixed with a high degree of homogeneity due to the mixing chamber's 360-degree rotation. Cycle times are typically in the 10-minute range. You can adjust the mixing time on the control panel based on the liquidity of your product.

High stability, low cost, and no material storage during mixing.

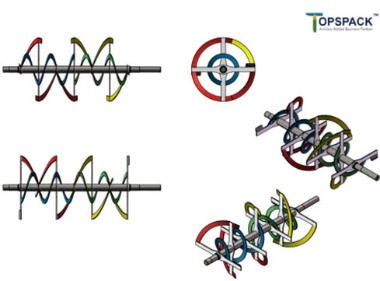

Ribbon Mixer

It is commonly used to blend powders, powder with liquid, powder with granules, and even the small amount of components. A ribbon mixer is recognized by its horizontal U-shaped design and revolving agitator. The agitator consists of helical ribbons that allow convective motion to flow in two directions, resulting in the mixing of powder and bulk particles. It has reliable operation, stable quality, low noise, a long life, and is easy to install and maintain.

Single-Shaft Paddle Mixer

It has been shown to be useful for mixing powders, granular materials, and bulk materials with liquids or pastes. It can be used with rice, beans, flour, nuts, or any other granular components. Cross-mixing is caused by a varied angle of the blades mixing up the product inside the machine. It has good quality, resulting in intensive mixing and a high mixing effect.

Double-Shaft Paddle Mixer

A twin-shaft paddle mixer or a no-gravity mixer can be used to combine powder and powder, granular and granular, granular and powder, and liquids in small amounts. It has a high-precision mixing machine that produces a perfect blend of ingredients with varying gravity, proportion, and particle size. It creates portion fragmentation by joining fragmentation equipment.

Post time: Dec-09-2022