Are you looking for mixers for a range of purposes?

You're in the right way!

This blog will help you to find out the effectiveness of a double conical mixer.

So, if you want to learn more, check out this blog.

View the video below:

What is Double Conical Mixer?

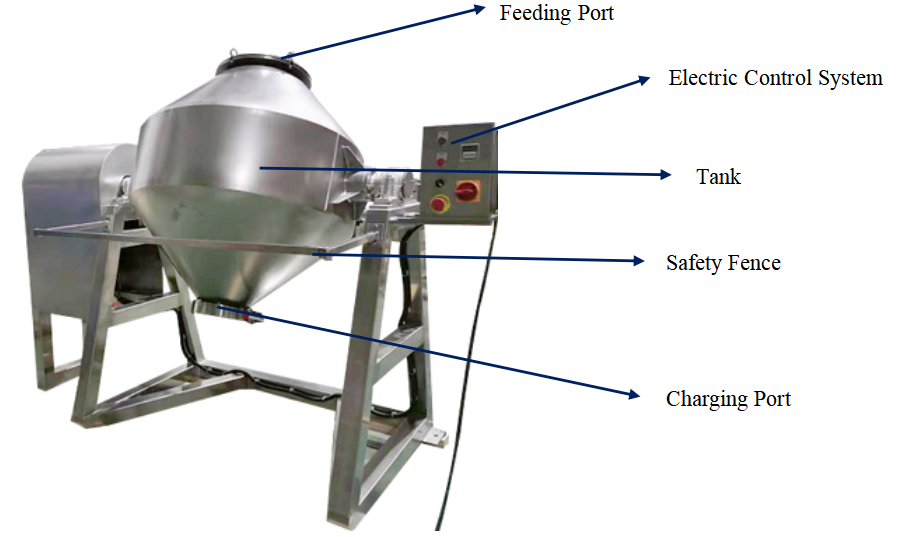

This double conical mixer is made up of the support part, mixing tank, motor, and electrical cabinet. Dry mixing of free-flowing solids is the primary application for the double conical mixer. Materials are processed manually or by vacuum conveyor and fed into the mixing chamber through an instant feed port. Because of the mixing chamber's 360-degree rotation, materials are thoroughly mixed with a high level of uniformity. Cycle times are typically in the tens of minutes. Depending on the liquidity of your product, you can adjust the mixing time on the control panel.

Construction of Double Conical Mixer:

The Security Operation

When the safety fence on the machine is opened, the machine automatically stops, keeping the operator safe.

There are multiple designs to select from.

Fence Rail Open Gate

The Tank's Interior

• The interior has been entirely welded and polished. Discharge is simple and sanitary because there are no dead angles.

• It has an intensifier bar to boost mixing efficiency.

• The tank is made entirely of stainless steel 304.

Rotary scrapers

Fixed scraper

Rotary bars

There are multiple designs to select from.

The Electric Control System

-Depending on the material and mixing procedure, the mixing time can be adjusted using a time switch.

-An inch button is used to adjust the position of the tank for feeding and discharging materials.

-A heating protection setting prevents the motor from overheating.

Charging Port

Stainless steel materials

It's the way to discharge the mixing materials from the inside of the tank.

Manual butterfly valve

Pneumatic butterfly valve

The Tank

The tank is constructed of stainless steel. It comes in a variety of sizes and, of course, can be customized.

The Specification:

| Item |

TP-W200 |

TP-W300 | TP-W500 | TP-W1000 | TP-W1500 | TP-W2000 |

| Total Volume | 200L | 300L | 500L | 1000L | 1500L | 2000L |

| Effective Loading Rate | 40%-60% | |||||

| Power | 1.5kw | 2.2kw | 3kw | 4kw | 5.5kw | 7kw |

| Tank Rotate Speed | 12 r/min | |||||

| Mixing Time |

4-8mins |

6-10mins | 10-15mins | 10-15mins | 15-20mins | 15-20mins |

| Length |

1400mm |

1700mm | 1900mm | 2700mm | 2900mm | 3100mm |

| Width |

800mm |

800mm | 800mm | 1500mm | 1500mm | 1900mm |

| Height |

1850mm |

1850mm | 1940mm | 2370mm | 2500mm | 3500mm |

| Weight | 280kg | 310kg | 550kg | 810kg | 980kg | 1500kg |

Application Industry:

The double conical mixer is used in dry solid mixing products and used in the following application:

Pharmaceuticals: mixing prior to powders and granules

Chemicals: metallic powder mixtures, pesticides, and herbicides and many more

Food processing: cereals, coffee mixes, dairy powders, milk powder and many more

Construction: steel pre-blends, etc.

Plastics: mixing of master batches, mixing of pellets, plastic powders, and many more

Post time: Aug-29-2022