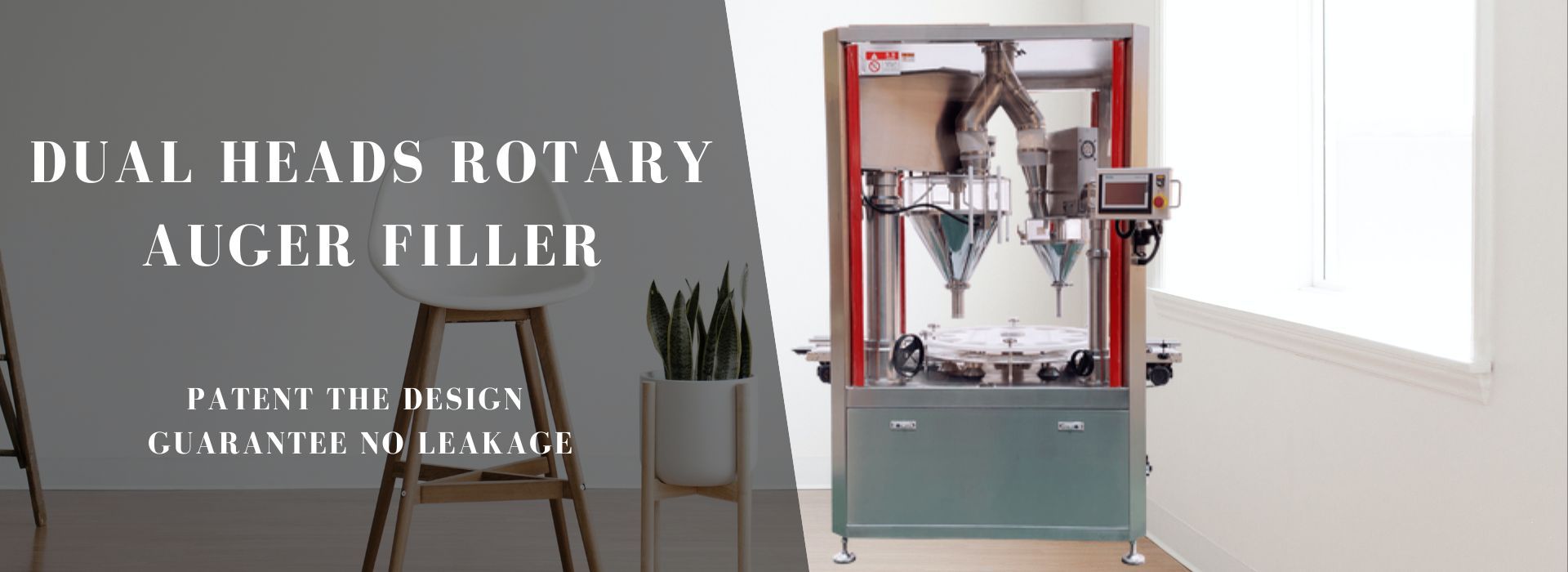

What’s Dual Heads Rotary Auger Filler?

This filler is the most recent innovation and structure, based on market development needs and in accordance with national GMP certification standards. The machine incorporates the most recent European packaging technology concepts, and the design is more reasonable, stable, and reliable. We increased the original 8 stations to 12. As a result, the turntable's single rotation angle has been greatly reduced, significantly improving the running speed and stability. The equipment can handle jar feeding, measuring, filling, weighing feedback, automatic correction, and other tasks automatically. It can be used to fill powder-like materials like milk powdered, etc.

What’s the Principle?

Two fillers, one for fast and 80% target weight filling and the other for gradually supplementing the remaining 20%.

Two load cells, one after fast filler to detect how much weight the gentle filler needs to supplement, and the other after gently filling to remove reject.

How Does Dual heads filler Work?

1. The main filler will quickly reach 85% of the target weight.

2. The assistant filler will supplant the left 15% accurately and gradually.

3. They collaborate to achieve high speed while ensuring high precision.

Application Industry

Regardless of the application, it can help a wide range of industries in many ways.

Food Industry - milk powder, protein powder, flour, sugar, salt, oat flour, etc.

Pharmaceutical Industry – aspirin, ibuprofen, herbal powder, etc.

Cosmetic Industry – face powder, nail powder, toilet powder, etc.

Chemical Industry – talcum powder, metal powder, plastic powder, etc.

Advantages of Using Dual Heads Rotary Auger Filler

1. Touch screen, PLC control system, and clear working mode

2. Rotary type, two sets of weighing and detection devices, and real-time feedback to ensure that no defective products are produced during the packaging process.

3. The automatic turntable can precisely position the jars, resulting in no bottle, no filling. The 2 sets of vibration devices effectively reduce material volume.

4. The overall structural design is sound. There are no dead corners that need to be cleaned. Changing the jar specification is simple and quick.

5. It is intended for use as a secondary supplement after weighing to improve accuracy and speed significantly.

6. Automatic empty jar peeling and double weight check. A trace of circular supplement.

7. Panasonic servo motor drive screw and rotary operation, precision planetary reducer, precise positioning, and high precision.

8. Completely sealed and filled, with lifting jar and two sets of vibration and dust cover devices.

Vibration & weighing

1. The vibration is located between two fillers and connects to the can holder.

2. Two load cells indicated by blue arrows are isolated from vibration and will not affect accuracy. One is used to weigh the current weight after the first main filling, while the other is used to detect whether the final product has reached the target weight.

Reject Recycling

Rejects will be recycled and added to empty can lines before accepting a second supply.

Post time: Sep-21-2022