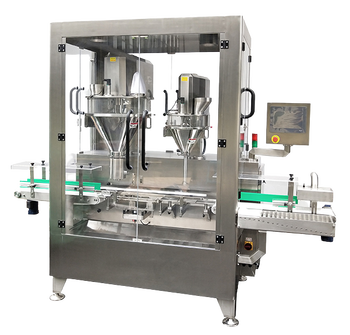

This series of machines is a brand-new design that we developed by repurposing the old Turnplate Feed on one side. You will fully comprehend the purpose and operation of a filling machine line after reading this blog. Read more and learn something new.

What is Filling Machine Line?

The filling machine line within one main-assist filler and the originating feeding system can maintain high precision while eliminating the time-consuming turntable cleaning. It is capable of accurate weighing and filling, and it can also be combined with other machines to form a complete can-packing production line.

How to Process?

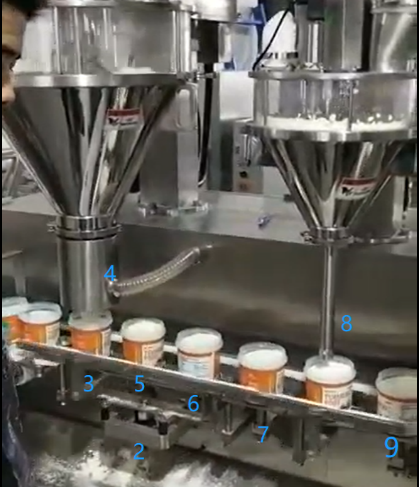

1.can in → 2.can-up → 3. first vibration → 4. filling → 5. second vibration → 6. third vibration → 7. weighing & tracing → 8. supplement → 9. weight checking → 10. Can out

What Products can Filling Machine Line Handle?

Regardless of the application, it can help a wide range of industries in many ways.

Food Industry - milk powder, protein powder, flour, sugar, salt, oat flour, etc.

Pharmaceutical Industry – aspirin, ibuprofen, herbal powder, etc.

Cosmetic Industry – face powder, nail powder, toilet powder, etc.

Chemical Industry – talcum powder, metal powder, plastic powder, etc.

High-Quality Performance

1.One-line dual fillers, main and assist filling to maintain high-precision work.

2.Can-up and horizontal transmitting are controlled by servo and pneumatic systems, allowing for greater accuracy and speed.

3. A servo motor and servo driver control the screw, ensuring its stability and accuracy.

4. Stainless steel structure, split hopper with polished inner-out, allows for easy cleaning.

5.The PLC and touch screen make operation simple.

6.A quick response weighing system converts the strong point into a real one.

7.The handwheel facilitates the exchange of various filings.

8.A dust-collecting cover is installed over the pipeline to protect the environment from pollution.

9.The machine's horizontal straight design saves space.

10. No metal pollution is produced by the screw setup.

11.With a centralized control system for the entire system.

The Weighing & Vibration

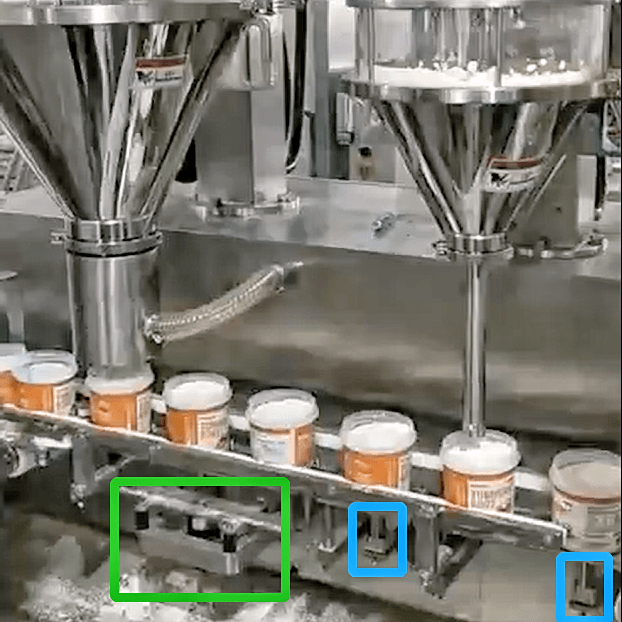

1. The vibration in the green square has three shaking points, which allows the vibrating range to be extended to three cans at once.

2. The two load cells in the blue square are isolated from vibration and will not affect accuracy. The first is used to weigh the current weight after the first main filling, and the second is used to detect whether the final product has reached the target weight.

Augers and Nozzles of Various Sizes

The auger filler principle states that the volume of powder brought down by the auger turning one circle is fixed. As a result, different auger sizes can be used in different filling weight ranges to achieve greater accuracy and save time. Each auger size has a corresponding auger tube. For instance, dia. The 38mm screw is suitable for filling 100g-250.

Post time: Sep-16-2022