A horizontal powder blender changes the way labs handle mixing. This machine fits easily into small spaces and keeps the work area safe. The horizontal powder blender uses advanced safety features to protect users during operation. Labs with strict standards trust the horizontal powder blender for its reliable performance. The compact size of the horizontal powder blender suits crowded labs. Many users choose the horizontal powder blender for its adaptability. It handles many mixing tasks with ease. The horizontal powder blender helps labs save space while improving results.

Key Takeaways

• Horizontal powder blenders improve lab mixing by providing efficient and consistent results, making them ideal for various materials.

• Safety features like a safety grid and interlock system protect users, reducing the risk of accidents during operation.

• Easy cleaning and maintenance features, such as Clean-in-Place systems, help prevent contamination and save time in busy labs.

• The compact design of horizontal blenders allows them to fit into small lab spaces, maximizing efficiency without sacrificing performance.

• Adjustable mixing speeds and flexible stirrer options enhance the versatility of horizontal blenders for different mixing tasks.

Lab Mixing Challenges

Uneven Results

Many labs struggle with uneven results when using conventional mixers. The design of traditional mixers often leads to inefficient mixing. Several factors contribute to this problem:

• Inadequate submersion of impellers can leave some materials unmixed.

• Vortices may form, introducing air and reducing the quality of the final blend.

• Product loss can occur when mixing is ineffective at low levels.

A study on mixing dynamics in double-cone blenders found that while axial mixing can finish quickly, radial mixing often remains poor. The shape and fill level of the vessel play a big role. When the vessel is filled to 80% instead of 50%, segregation and poor mixing outcomes become more likely. These issues show that vessel geometry and filling level are critical for achieving even results.

Contamination Risks

Contamination is a serious concern in laboratory environments. When mixers are hard to clean or have many small parts, residues from previous batches can remain. This leftover material can mix with new samples, leading to inaccurate results. Cross-contamination can also occur if the same equipment is used for different substances without proper cleaning. Labs must take extra care to avoid these risks, especially when working with sensitive or hazardous materials.

Tip: Choose mixers with smooth surfaces and easy-access cleaning features to reduce contamination risks.

Manual Mixing Hazards

Manual mixing exposes lab staff to several hazards. Repetitive motions can cause strain or injury over time. Handling powders by hand increases the chance of spills, dust inhalation, or skin contact with chemicals. These risks can lead to health problems and compromise lab safety. Automated mixers help reduce these dangers by keeping operators away from direct contact with materials.

Horizontal Powder Blender Features

Efficient Mixing Performance

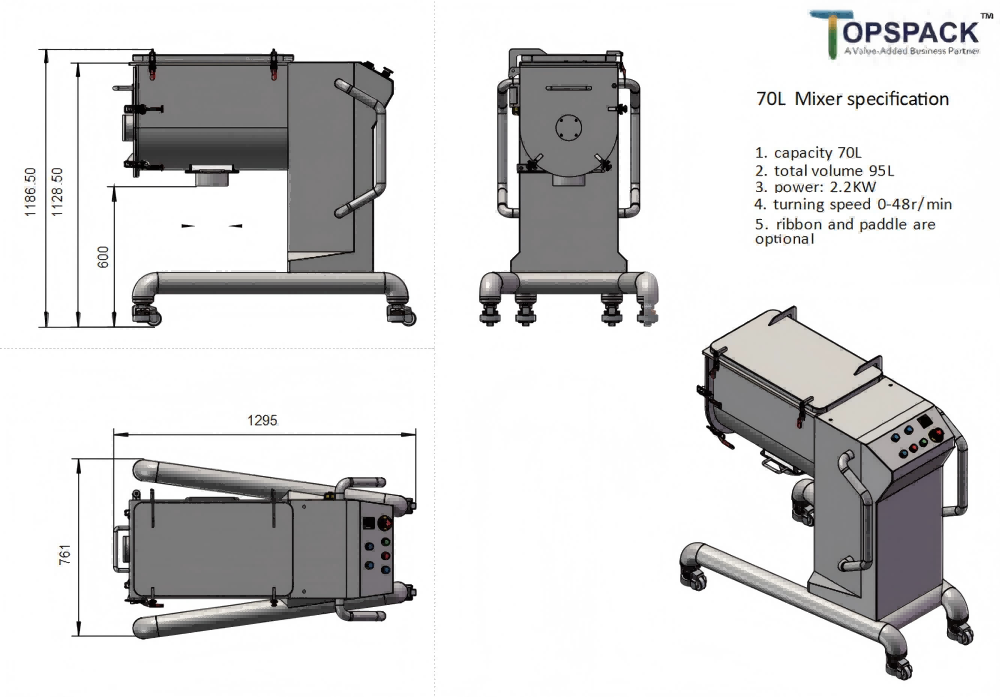

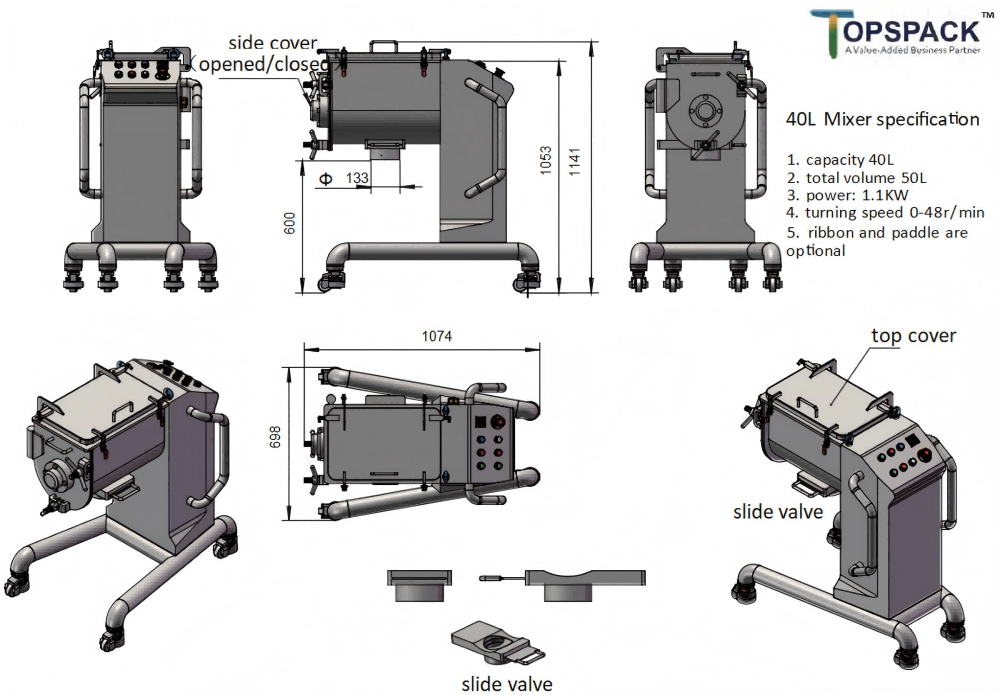

Horizontal ribbon mixer technology stands out for its ability to deliver rapid and thorough mixing. The counter-rotating ribbons inside the ribbon blender create a complex flow pattern. This design ensures that powders and granules move in multiple directions, which leads to high mixing efficiency. Many labs choose the horizontal ribbon mixer because it achieves a high level of homogeneity faster than other blenders. The TDPM40S and TDPM70S models offer effective volumes of 40 liters and 70 liters, making them suitable for labs with different capacity needs. The horizontal ribbon mixer adapts to a wide range of powder types and additives, which is important for research and development. The flexibility to switch between ribbon and paddle stirrers allows users to optimize mixing performance for each application. The powder ribbon mixer also features a variable frequency drive (VFD), which lets users adjust the speed for precise control. This efficient mixing equipment helps labs achieve consistent results, even with challenging materials.

Safety and User-Friendly Design

Safety is a top priority in laboratory environments. The horizontal ribbon blender includes several advanced safety features that protect users and ensure compliance with lab standards. The safety grid prevents accidental contact with moving parts. The interlock system stops the machine if the safety grid is not properly closed. The control panel is easy to use and allows operators to monitor the blending process. The table below summarizes key safety features found in modern ribbon blender designs:

|

Safety Feature |

Description |

|

Fully clamped rotating parts |

Prevents the bin from falling during the blending process |

|

Appropriate sensors |

Stops the machine in case of unauthorized access |

|

Electrical cut out |

Protects against electrical faults and prevents motor burnout |

|

Isolated moving components |

Prevents access to moving parts during operation |

|

Emergency stop switch |

Allows for immediate machine shutdown in emergencies |

|

Auto-lock systems |

Locks the bin after loading to ensure safety during blending |

|

Interlocking systems |

Ensures operations occur in a safe, sequential manner |

|

No dead angles or exposed screws |

Reduces the risk of accidents for technicians |

|

Dust-free and low noise operations |

Enhances user safety by minimizing air pollution |

The horizontal ribbon mixer also operates with low noise and minimal dust, which improves the work environment. The powder ribbon mixer’s compact design fits easily into crowded labs, reducing clutter and making it easier to maintain a safe workspace.

Easy Cleaning and Maintenance

Cleaning and maintenance are essential for preventing contamination in lab mixing. The horizontal ribbon blender offers several features that make cleaning simple and effective. The side-opening door provides easy access to the mixing chamber. Smooth surfaces and minimal dead angles help prevent residue buildup. Many ribbon blender models support Clean-in-Place (CIP) systems, which automate the cleaning process. CIP technology removes residues and contaminants without dismantling the equipment. This feature is especially important for labs working with sensitive powders or bacterial materials.

• Clean-in-Place systems automate cleaning and reduce cross-contamination risks.

• CIP ensures thorough removal of residues without disassembly.

• Fast and complete cleaning maintains product integrity in pharmaceutical and food labs.

Material and surface treatment options also play a role in cleaning and durability. The horizontal ribbon mixer can be constructed from carbon steel or stainless steel (SS304, SS316L), depending on the application. Surface treatments such as Teflon coating and mirror polishing make cleaning easier and extend the life of the equipment. Some ribbon blender models offer additional treatments for enhanced wear resistance:

|

Surface Treatment Options |

Description |

| Carburizing | Enhances surface hardness |

| Nitriding | Improves wear resistance |

| Tungsten Carbide Spray | Provides a tough, wear-resistant surface |

For added protection against wear, product-contacting moving parts of the ribbon blender may be hard chrome plated.

Material compatibility and drive design allow the ribbon blender to meet the needs of different lab applications. Special features, such as flexible stirrer configurations and adjustable speed, make the horizontal ribbon mixer a reliable choice for labs that require efficient mixing equipment with easy maintenance.

Key Benefits for Lab Mixers

Time and Space Savings

Labs often need to maximize both time and space. The ribbon blender offers a compact design that fits easily into crowded work areas. This mixing equipment allows users to process small batches without moving large machines. The TDPM40S and TDPM70S models provide enough capacity for most lab tasks. These mixers help labs complete mixing and blending jobs quickly. The variable frequency drive lets operators adjust speed for fast and efficient results. With a side-opening door and smooth surfaces, cleaning takes less time. This means more time for research and less time spent on maintenance.

Consistent, Reliable Results

Consistency is important in every lab. The ribbon blender uses a unique mixing action to ensure all powder and granule materials blend evenly. This leads to high quality mixtures every time. The flexible stirrer options allow labs to switch between ribbon and paddle types for different mixing needs. The table below shows how these mixers support research and development, pilot plants, and small-scale production:

|

Feature |

Description |

| Ideal Use | Proof of concept testing in recipe development and small volume blending |

| Capacity | Accommodates low volumes through 100L and 200L IBCs |

| Discharge Mechanism | Manual cone valve for mass-flow discharge of powders |

| Mixing Capability | Addition of an Intensifier for high shear mixing |

| Monitoring | MicroNIR spectrometer for blend homogeneity assessment |

The ribbon blender also supports industries like pharmaceutical, nutraceutical, chemical, and food processing. This mixing equipment ensures quality and consistency for every batch.

Reduced Error and Injury Risk

Safety is a top concern in any lab. The ribbon blender includes a safety grid and interlock system to protect users. These mixers reduce the risk of accidents during mixing and blending. The enclosed design keeps powder inside the chamber, lowering the chance of spills or dust exposure. The easy-to-use control panel helps prevent operator errors. These features make the ribbon blender a reliable mixing solution for labs that value safety and quality.

Tip: Choose ribbon blender models with adjustable speed and flexible stirrers for the best results in mixing and blending.

Practical Tips for Industrial Horizontal Mixers

Best Operation Practices

Proper setup and operation are important for getting the best results from a ribbon blender. Start by making sure the ribbon blender is placed on a stable, level surface. Always check that the safety grid and interlock system are working before starting the ribbon blender. When choosing between ribbon and paddle stirrers, consider the type of material you need to mix. The table below shows how each option affects mixing efficiency and product quality:

|

Feature |

Ribbon Blenders |

Paddle Mixers |

| Mixing Efficiency | More efficient for dry powders, achieving homogeneity quickly | Slower mixing speed, better for larger, denser materials |

| Impact on Particle Integrity | Higher mechanical energy may damage fragile particles | Preserves particle integrity, avoids excessive shear |

Use the ribbon blender for dry powders when you need fast, even mixing. Choose paddle stirrers if you want to protect fragile particles or mix heavier materials. The variable frequency drive (VFD) on the ribbon blender lets you adjust the speed for each batch. Lower speeds work well for small or delicate batches, while higher speeds help mix larger amounts quickly. Adjusting the VFD helps prevent overmixing and ensures all materials blend smoothly.

Tip: Always start the ribbon blender at a low speed and increase as needed. This helps avoid spills and ensures even mixing.

Maintenance for Safety

Regular maintenance keeps a ribbon blender safe and reliable. Clean the ribbon blender after every use to prevent material build-up and contamination. Inspect seals often and replace them if they show signs of wear. The table below lists important maintenance tasks for a ribbon blender:

|

Maintenance Task |

Description |

|

Regular Inspections |

Check all parts for wear and damage. |

|

Cleaning |

Clean inside and outside surfaces after each use. |

|

Lubrication |

Apply lubricant to moving parts to reduce friction. |

|

Seal Checks |

Inspect and replace seals as needed. |

|

Shaft Alignment |

Make sure shafts are straight to prevent damage. |

|

Drive Belts & Gearboxes |

Listen for unusual sounds and check for wear. |

|

Blades & Impellers |

Replace any damaged or corroded parts. |

|

Oil Change |

Change oil regularly for smooth operation. |

|

Attachments |

Use the correct attachments for each task and check for wear. |

|

Performance Testing |

Test speed, temperature, and flow rate to ensure proper function. |

A ribbon blender works best when you follow these steps. Regular maintenance and safety checks help prevent breakdowns and keep the ribbon blender running smoothly. These tips apply to all industrial horizontal mixers and help extend the life of your industrial mixer.

Horizontal powder blenders solve common lab mixing problems with advanced safety and efficient design. Labs report better results due to improved mixing mechanisms and reduced segregation, as shown below:

|

Key Findings |

Description |

| Mixing Mechanisms | Convection, diffusion, and shear improve mixture quality |

| Segregation Impact | Less segregation, even with different powder sizes |

| Flow Regimes | Cascading flow creates the most uniform blends |

Compared to other mixers, horizontal ribbon blenders offer faster blending, safer operation, and more complete discharge.

Labs seeking better workflow and safety should explore these solutions for future upgrades.

FAQ

What types of materials can the horizontal powder blender mix?

The blender can handle powders, granules, and small pellets. It works well with chemicals, pharmaceuticals, food ingredients, and nutraceuticals. Users can switch between ribbon and paddle stirrers for different material types.

How does the safety grid protect users?

The safety grid covers the mixing chamber. It prevents hands or tools from touching moving parts. The interlock system stops the blender if the grid is open.

Is the blender easy to clean?

Yes. The side-opening door gives quick access to the chamber. Smooth surfaces and special coatings help prevent residue. Many users clean the blender in minutes.

Can I adjust the mixing speed?

Yes! The Variable Frequency Drive (VFD) lets you control the speed. You can set the speed for gentle or fast mixing, depending on your material.

What sizes are available for lab use?

|

Model |

Effective Volume |

Power Output |

| TDPM40S | 40 liters | 1.1 kW |

| TDPM70S | 70 liters | 2.2 kW |

Both models fit well in labs with limited space.

Post time: Feb-06-2026