Introduction:

Looking for a Ribbon Blender Machine? Well, you’re on the right page. We sell the high-quality Mixing Machines that will make your powder mixing experience go to the highest point of satisfaction. Every machine is made in good-quality, spill-proof materials.

Products Ribbon Blender Machine can handle.

The only answer is “Yes”. Our Ribbon Blender Machine specializes in powder products like dry foods products, nutraceuticals, protein powder mixes, dry juice mixes, chemicals, fertilizer, insecticides, colorants, resins and polymers, and more.

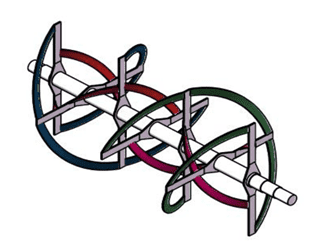

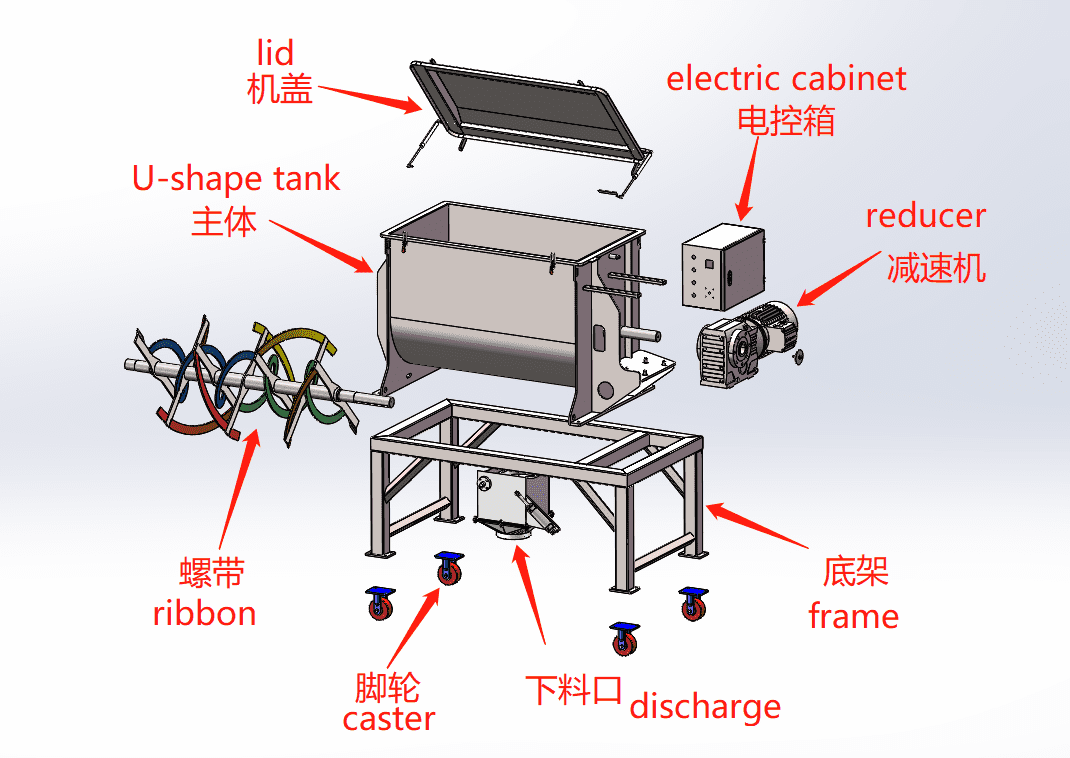

Ribbon Mixing Machine

It was called Ribbon Mixer because of the rotating blade that looks like a ribbon. It has a 2 mixing blade system to make every powder product mix perfectly well.

The outer blade makes everything in the middle go to both sides and the inner blade makes everything on the side go in the middle.

That makes it special because it can mix powder materials very well in a short period of time.

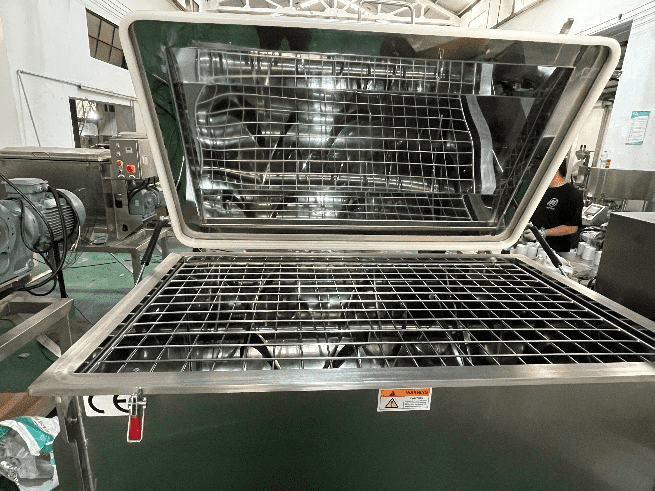

This Ribbon Mixing machine can be filled out from 100 to 10,000 liters of Powder products and It was designed in a “U” shape container to avoid any dead spaces and it had a full welding feature to avoid any spills and to discharge every single piece easily.

Main Features:

- All parts of the machines are fully welded stainless steel that will ensure that there’s no leak and your products won’t leave and pollute fresh powder.

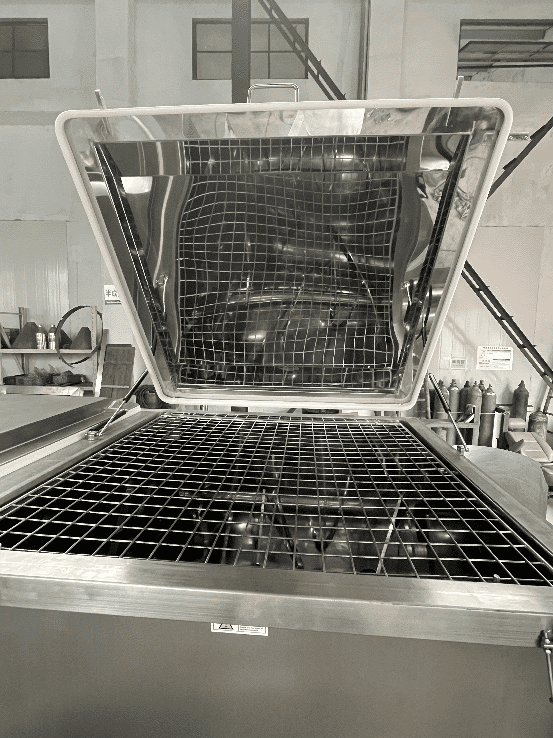

-It’s all 304 stainless steel, and full mirror polished inside the tank. That will allow you to clean powder contact part easily.

-The Special “U” design makes no dead angle when mixing your products.

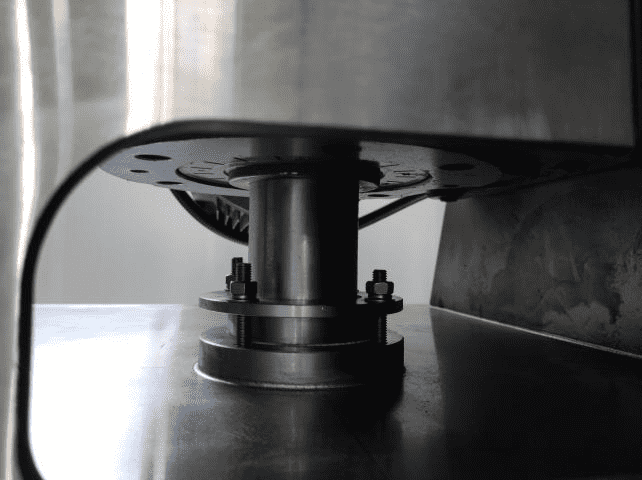

-Patent Technology on double security shaft sealing.

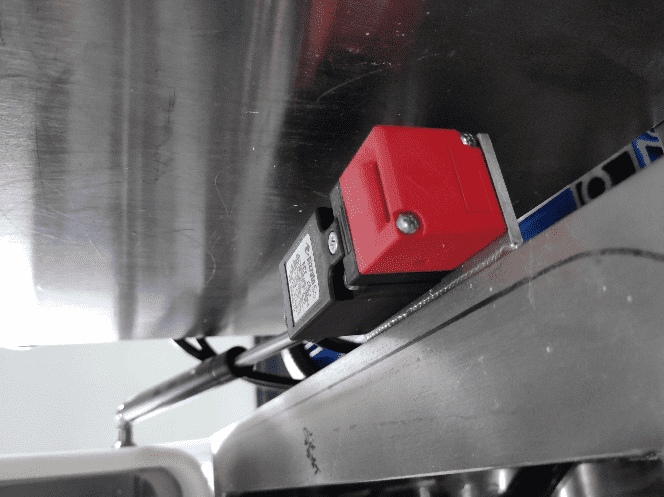

-The machine has a safety system that will not start unless the lid is closed. You should have a key to disable that feature.

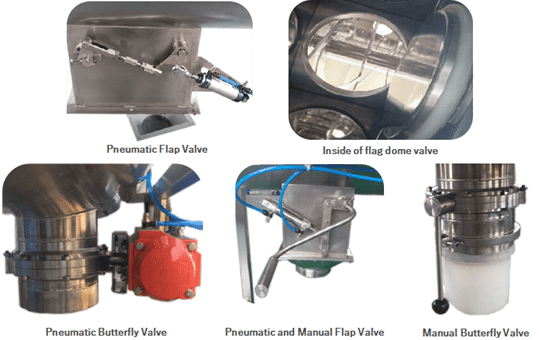

One of the best features of this Ribbon blender is the discharge valve. It’s an automatic system that will allow you to open and close the discharge valve using a switch only. It has an air cylinder to make sure that the valve is closed securely and it will be opened carefully without breaking the valve itself. It also has a silicone ring rubber aligned with the cover of the valve to make sure that there is no spill when you are in the mixing process.

It has a Slightly concave flap design controlled by pneumatic to achieve no leakage at the discharge valve. It also has a silicone ring to protect the lid when opening and closing it.

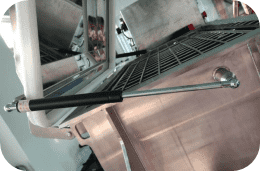

-It has a Round corner with a silicone ring on the lid for a gentle closing and opening of the lid. Slow rising keeps hydraulic stay bar long life.

-With safety interlock, safety grid, and wheels.

Discharge Valve

One of the best features of this Ribbon blender is the discharge valve. It’s an automatic system that will allow you to open and close the discharge valve using a switch only. It has an air cylinder to make sure that the valve is closed securely and it will be opened carefully without breaking the valve itself. It also has a silicone ring rubber aligned with the cover of the valve to make sure that there is no spill when you are in the mixing process.

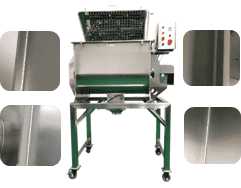

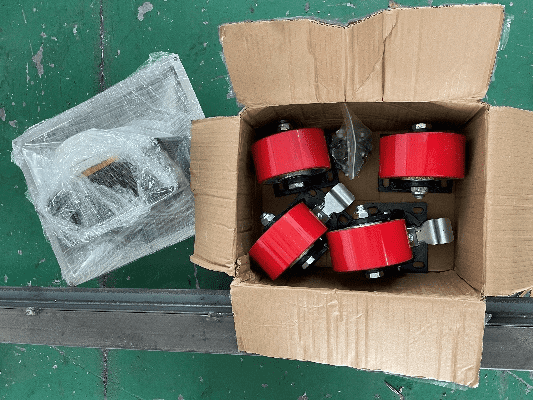

Caster & Ribbon Frame

The ribbon mixer has a heavy-duty stainless frame that can hold and lift the machine steadily. You can move the machine from one place to another easily without lifting it. It also has a locking system on wheels to make sure that the machine won’t go anywhere while you’re on the mixing process.

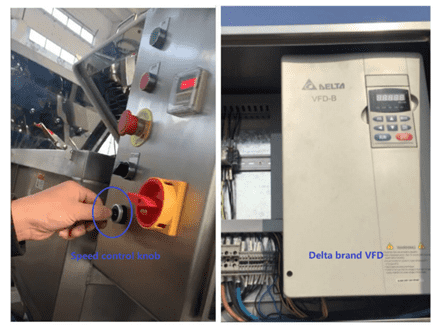

Control Panel

This Ribbon Mixer is very easy to use. All the buttons and switches are labeled correctly and it won’t make any confusion to the user. The speed of it can be customized into speed adjustable by installing a frequency converter. Everything you need to control the machine is all in one place.

Parts of Ribbon Blender

Specification:

|

Model |

TDPM 100 |

TDPM 200 |

TDPM 300 |

TDPM 500 |

TDPM 1000 |

TDPM 1500 |

TDPM 2000 |

TDPM 3000 |

TDPM 5000 |

TDPM 10000 |

|

Capacity(L) |

100 |

200 |

300 |

500 |

1000 |

1500 |

2000 |

3000 |

5000 |

10000 |

|

Volume(L) |

140 |

280 |

420 |

710 |

1420 |

1800 |

2600 |

3800 |

7100 |

14000 |

|

Loading rate |

40%-70% |

|||||||||

|

Length(mm) |

1050 |

1370 |

1550 |

1773 |

2394 |

2715 |

3080 |

3744 |

4000 |

5515 |

|

Width(mm) |

700 |

834 |

970 |

1100 |

1320 |

1397 |

1625 |

1330 |

1500 |

1768 |

|

Height(mm) |

1440 |

1647 |

1655 |

1855 |

2187 |

2313 |

2453 |

2718 |

1750 |

2400 |

|

Weight(kg) |

180 |

250 |

350 |

500 |

700 |

1000 |

1300 |

1600 |

2100 |

2700 |

|

Total Power (KW) |

3 |

4 |

5.5 |

7.5 |

11 |

15 |

18.5 |

22 |

45 |

75 |

Post time: Aug-24-2021