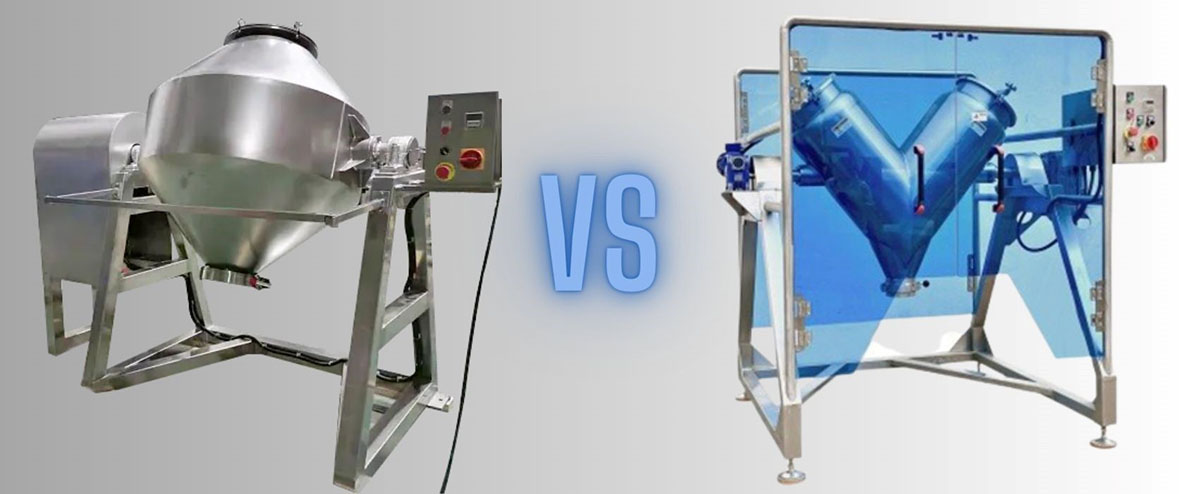

The primary distinctions between a "Double Cone Mixer and a V Mixer” is found in their geometries and mixing principles.

Here’s the following key factors on their differences:

Double Cone Mixer:

A “Double Cone Mixer” is made up of two conical-shaped vessels that joins together at their apexes to form a V-shape structure. The mixing chamber of this machine is shaped like an hourglass.

A “Double Cone Mixer” is made up of two conical-shaped vessels that joins together at their apexes to form a V-shape structure. The mixing chamber of this machine is shaped like an hourglass.

Mixing Principle:

To blend the materials, Double Cone Mixers is used for tumbling or cascading actions. The vessel's rotation causes the materials to roll from one-end of the cone to the other. In order to promotes the mixing and blending to it.

Double Cone Mixers is efficient and gently on mixing and blending process on dry powders, granules, and other free-flowing materials. However, when it comes to blending cohesive or sticky materials, they may be having a limitation on mixing and blending processing.

V Mixer:

V Mixers are also known as a V-shaped mixers. It is made-up of two-interconnected cylindrical chambers that are arranged in a “V Blending” shaped structure. It is manufactured for easier results. In order for the V-shaped configuration gains the best results in mixing and blending processing.

Blending Principle:

V mixers used in a blending principle known as the "V" or "tumbling" action. The ingredients are loaded into one of the chambers on it. The materials cascades from one shell to the other, and as the machine rotates, it creates a superb effect in mixing and blending processed.

Mixing Efficiency:

V mixers are versatile and can blend to dry powders, granules, and cohesive materials effectively. They are the most useful for mixing especially cohesive powders that agglomerate or form lumps.

Finally, the primary distinctions between a “Double Cone Mixer and a V Mixer” are their geometric shapes, mixing principles, and the materials for which they are best suited. Tumbling actions is used in a conical-shaped vessel in Double Cone Mixers, while cascading or tumbling action is used in two-interconnected cylindrical shells arranged in a form of V-shaped in a V Mixers. Each type of mixers has a distinct form and advantages and it’s better to choose an appropriate machine that is very suitable to your mixing and blending applications.

Post time: May-30-2023