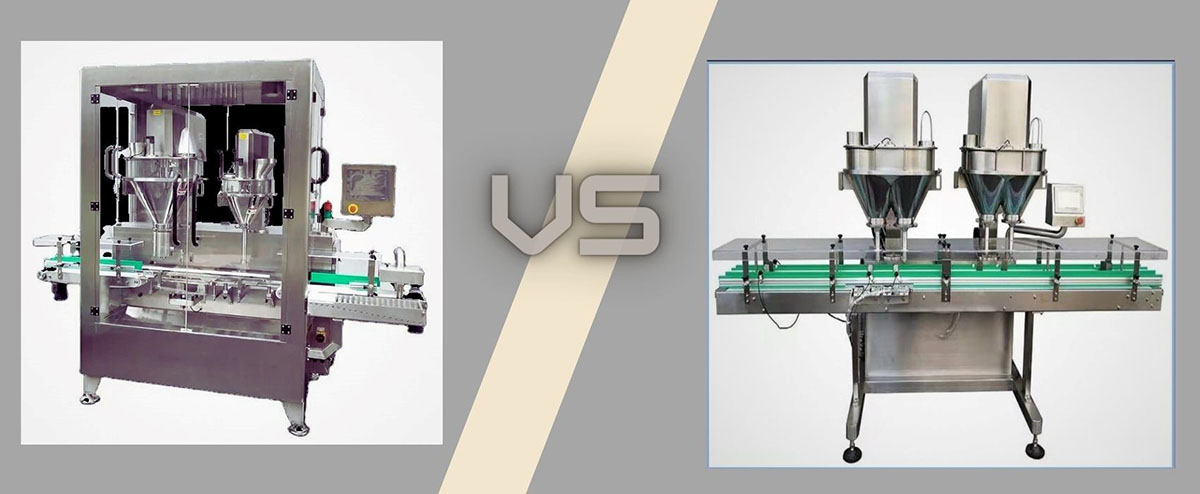

The primary distinction between a “Dual-Head Auger Filler and a Four-Head Auger Filler” are the number of auger filling heads.

The following are the key distinctions:

Auger Filler with Dual Heads:

The number of filling heads on a dual-head auger filler are two.

Filling Capacity:

It can fill up to two different products at the same time as well as it can increase the filling speed on a single production by using both heads.

Dual-Head Auger Fillers are commonly used to fill powders, granules, and other free-flowing materials into containers such as bottles, jars, etc.

Efficiency:

Because this machine has two heads, this machine has a faster filling speed than the Single-Head Fillers, which helps to increase production rates.

Flexibility:

Dual-Head Auger Fillers allows the simultaneous filling of multiple products into separate containers, reducing the needs for additional machines and a saving space as well.

Space and Cost:

They are generally take-up less space and may be less expensive than a Four-Head Fillers.

Auger Filler with Four Heads:

The number of filling heads on a four-head auger filler is four.

Filling Capacity:

It can fill-up to four different products at the same time as well as significantly increase the filling speed of a single using this kind of machine.

Applications:

Four-Head Auger Fillers are commonly used in high-volume production settings where multiple products must be filled quickly and efficiently.

Efficiency:

Since this machine has four heads, this machine has a faster filling speed than a Dual-Head Fillers. Having four heads, this allows the production rates increase as well and automatically increases the overall productivity.

Versatility:

With these four heads, diverse products can be filled at the same time, making it ideal for all operations that requires a quicker change of product.

Due to the additional filling heads, four-headed auger fillers may be required more space and it can be more expensive than dual-head fillers.

It is perilous to consider to some factors that as required a production volume, filling speed, product variety, space availability, and budgetary considerations. When deciding between the Dual-Head Auger Filler and a Four-Head Auger Filler, your choices is determined by your respective application's specific needs and to your production requirements.

Post time: May-30-2023