Mini-type ribbon mixer performance is heavily influenced by design and setup.

Here are some guidelines and considerations for optimizing the design and configuration of such mixers:

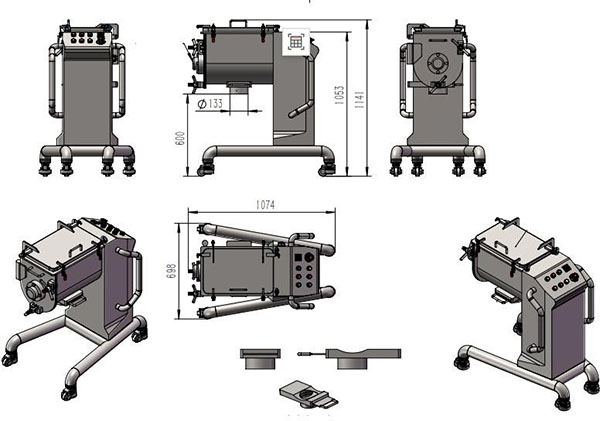

Mixer Size and Capacity:

Based on intended application, determines the suitable mixer size and capacity. Mini-type ribbon mixers typically have capacities ranging from a few liters to tens of liters. To establish the best mixer dimensions, consider the batch size and throughput requirements.

Geometry of the Mixing Chamber:

The mixing chamber should be built and to allow for efficient mixing while avoiding dead zones or stagnant sections. Mini-type ribbon mixers are typically rectangular or cylindrical in shape. The length, width, and height of the chamber should be carefully chosen to provide enough material circulation and good effectivity in mixing.

● Ribbon Blade Design: The ribbon blades are the mixer’s major mixing elements. The ribbon blade design, affects mixing efficiency and homogeneity. Consider the following elements:

● Ribbon Blade Design: The ribbon blades are the mixer’s major mixing elements. The ribbon blade design, affects mixing efficiency and homogeneity. Consider the following elements:

● Ribbon blades are often designed with a double-helix structure. Material mobility and mixing are aided by the helical form. The helix’s angle and pitch can be modified to improve mixing performance.

● Blade clearance should be optimized between the ribbon blades and the chamber walls. Ample space promotes optimum material flow without undue friction, while reducing the likelihood of material buildup and clogs.

● Blade Material and Surface Finish: Based on the application and the materials being mixed, choose a suitable material for the ribbon blades. The blade surface should be smooth, to reduce material adhesion and make cleaning easier.

Material Inlet and Outlet:

Make sure the mixer’s material inlets and outlets are well-designed for easy loading and unloading. Consider the placement and size of these holes to ensure smooth material flow and prevent material segregation or accumulation. Include suitable safety measures in the design, such as emergency stop buttons, safety guards, and interlocks, to prevent unauthorized access to moving parts.

Make sure the mixer’s material inlets and outlets are well-designed for easy loading and unloading. Consider the placement and size of these holes to ensure smooth material flow and prevent material segregation or accumulation. Include suitable safety measures in the design, such as emergency stop buttons, safety guards, and interlocks, to prevent unauthorized access to moving parts.

Simple Cleaning & Maintenance:

Create a mixer with removable parts or access panels for easy cleaning and maintenance. Smooth and crevice-free surfaces are preferred to reduce material residue and allow for complete cleaning.

To end this one, Mini-Type Ribbon Mixers and other types of machine mixers must be initiated with a simple cleaning and maintenance and do checking of its parts thoroughly in order to maintain its best operational duties, durability and more effective in mixing processing.

Post time: Jun-27-2023