Are you looking for an impactful V-mixer machine? You're on the right path when it comes to selecting the best fit model for your products. Please keep reading.

Shanghai Tops Group has been in the packing machine industry for over 21 years. We are experts in mixing, filling, and packaging equipment for any industry. We have sold machines in over 80 countries worldwide.

Please click this video:

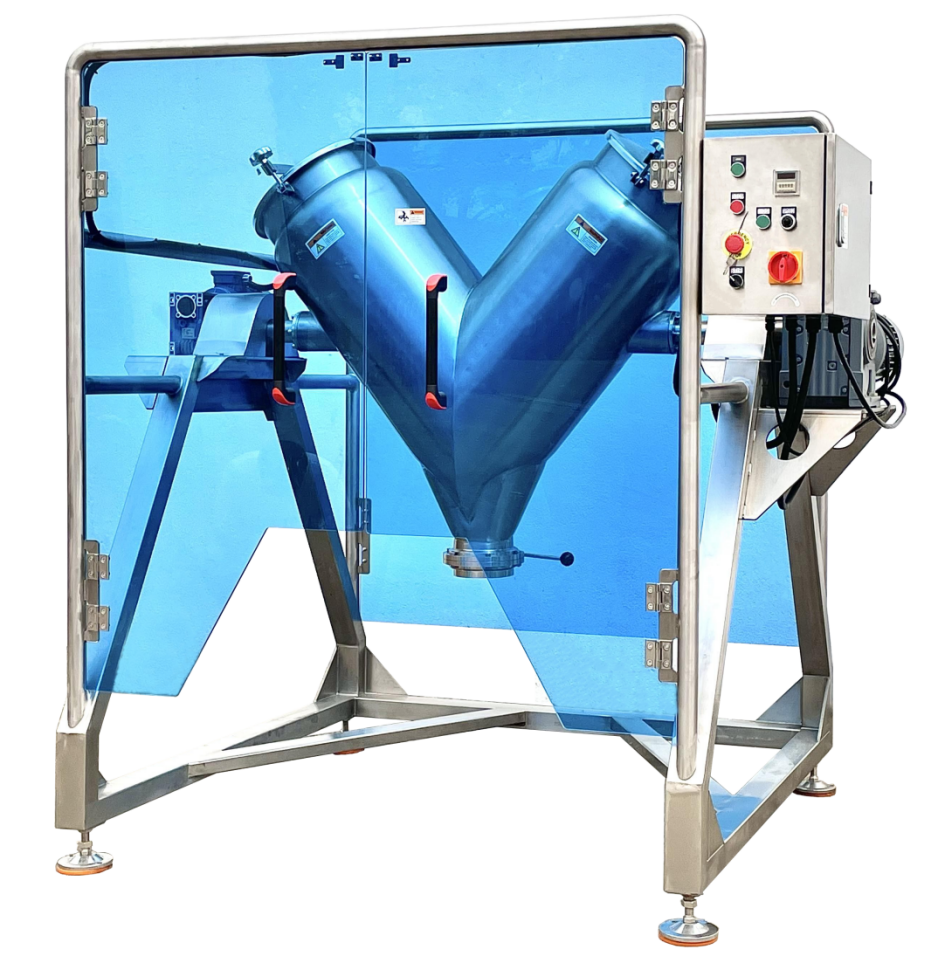

Here's the Tops Group's high-quality V-mixer machine

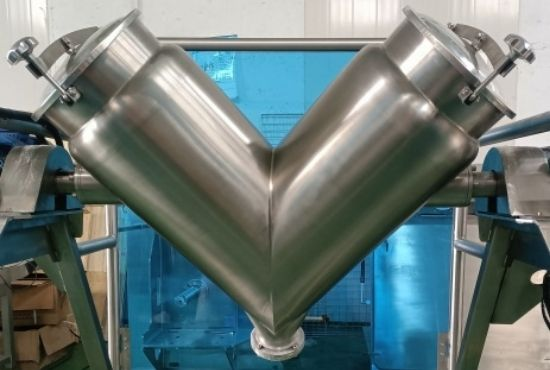

The Tops Group's V mixer is made up of various components such as a mixing tank, a frame, a transmission system, and an electrical system. It uses two symmetric cylinders to create a gravitational mix that causes materials to constantly gather and scatter. It takes 5 to 15 minutes to evenly combine two or more powdered or granular materials. The recommended fill-up volume for a blender is 40 to 60% of the total mixing volume. The mixing uniformity is greater than 99%, implying that the product in the two cylinders moves into the central common area with each turn of the v mixer, a continuous process. The inner and outer surfaces of the mixing tank are fully welded and polished with precision processing, resulting in a smooth, flat, dead angle-free surface that is easy to clean.

The Tops Group V mixer has a stainless-steel square tube base and a stainless-steel round tube frame. It has a unique design, is fully secure, and is simple to clean.

Our v mixer has a safety plexiglass door with a safety button, and the machine automatically stops when the door is open, keeping the operator safe.

The outer surface is fully welded and polished; there is no material storage, and cleaning is simple and safe. All materials are stainless steel 304.

The interior is fully welded and polished. Discharging is simple and hygienic, with no dead angles. It has a removable (optional) intensifier bar that aids in increasing mixing efficiency.

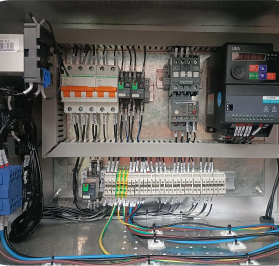

The frequency converter allows for speed adjustment. Mixing time can be adjusted using a timer based on the material and mixing process. An inch button is used to turn the tank to the proper charging (or discharging) position for feeding and discharging materials. It has a safety switch for the operator's safety and to prevent personnel injury.

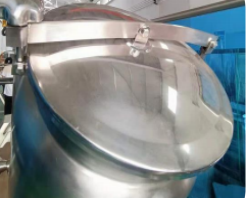

The feeding inlet has a movable cover that is easily operated by pressing the lever. It is a stainless-steel edible silicone rubber sealing strip with good sealing performance and no pollution.

A representation of the powder mixture being charged inside the tank.

More information is available at the following link

Tops Group mixing machines can give you a more satisfying consumer experience.

Send an inquiry right now!

Post time: Aug-29-2022