What is packaging line?

Let's learn what packaging line for powder products is, how it works, which products are meant to be used, and a lot more.

A packaging line for powder products is an interconnected series of equipment and machinery used to transform goods into their final packaged form throughout the packaging process. It often comprises an assortment of automated or semi-automated machines that manage various packaging processes, including filling, capping, labeling, and sealing. Various powder materials are ideal for packaging lines.

Packaging line for powder products industries: Food and beverage packaging lines, pharmaceuticals, personal care items, household goods, and other industries.

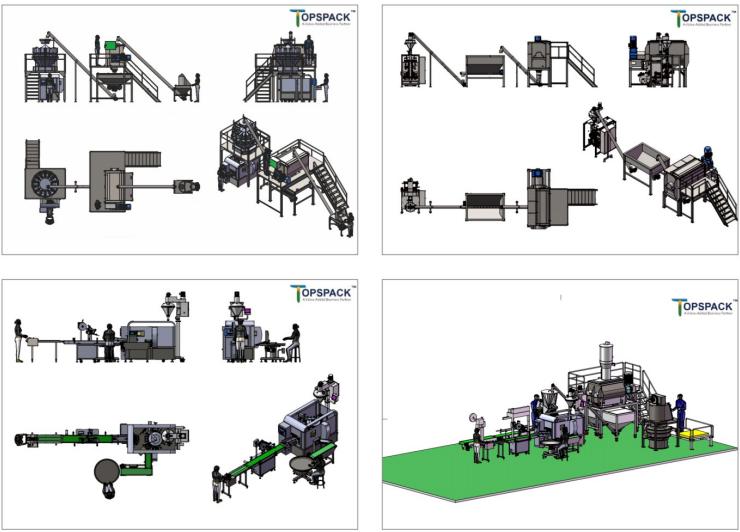

Set A packaging line for powder products.

Bottle unscrambler + auger filler + automatic capping machine + foil sealing machine

Set B packaging line for powder products

Bottle unscrambler + auger filler + automatic capping machine + foil sealing machine + labeling machine

We also have different set of powder mixing and packing system:

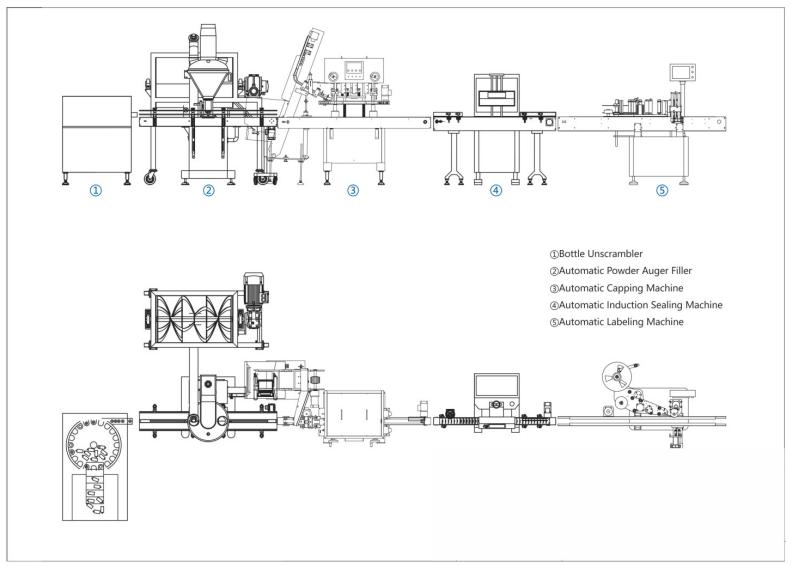

It can be linked with bottle unscrambler + automatic powder auger filling + automatic capping machine + automatic induction sealing machine + automatic labeling machine.

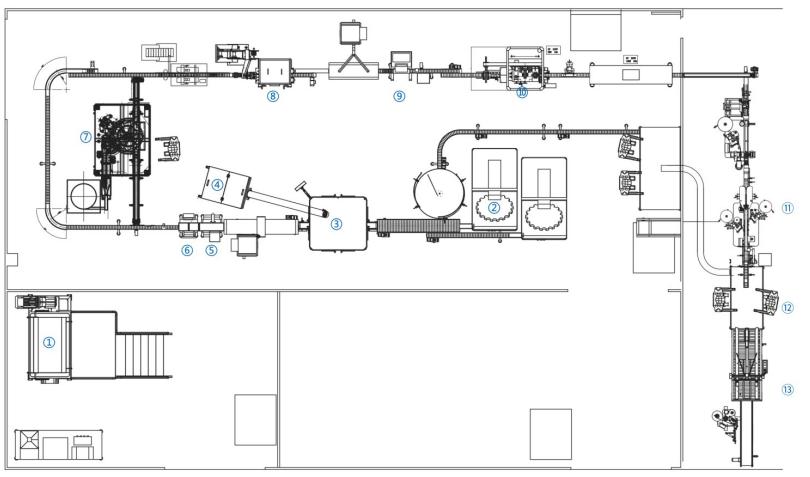

It can be linked as well with mixing machine + bottle unscramble + dual head auger filler + screw conveyor + metal detector + weight checker + automatic rotary capping machine + automatic linear capping machine + induction sealer + sleeve labeler + multi-function labeler + packing table + cartooning machine.

The most common components of a packaging line include:

Filling Machine: This filling machine can measure, fill, and do more functions. The machine is ideal for packing both flowable powders, such as milk powder, and granular illiquid items because of its creative, well-designed structure. As it makes use of a specialized auger filler and computer-based real-time tracking, it is also incredibly precise and efficient.

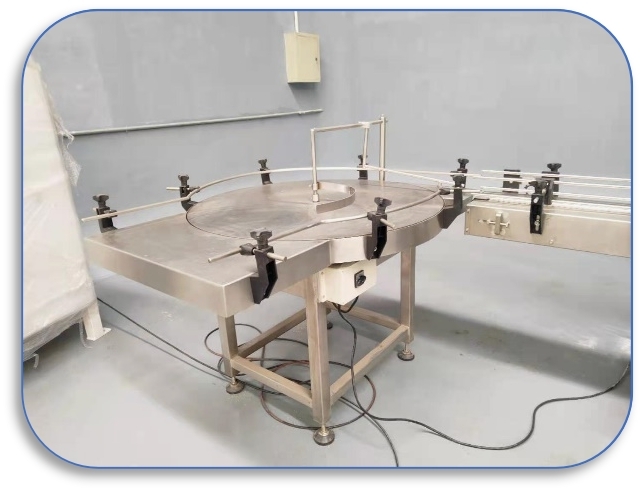

Conveyors: They transport goods beside the packaging line. guaranteeing the seamless flow of materials across multiple packaging machines. Depending on what is needed for the packaging process, they might be belt conveyors, roller conveyors, or another kind.

Capping Machine: A bottle-capping machine's task is to screw on bottle caps automatically. This is specifically made to work with packaging systems that are automated. This machine is a continuous capping machine, as opposed to the typical intermittent variety. This machine works better at pressing the lids securely and causing less puncturing than intermittent capping.

Labeling Machine: This machine is easy to operate, independent, and reasonably priced. It features a touch screen that is immediately teachable and programmable. On the integrated microprocessor, different task parameters are recorded to enable a simple and quick switchover.

Post time: Apr-03-2024