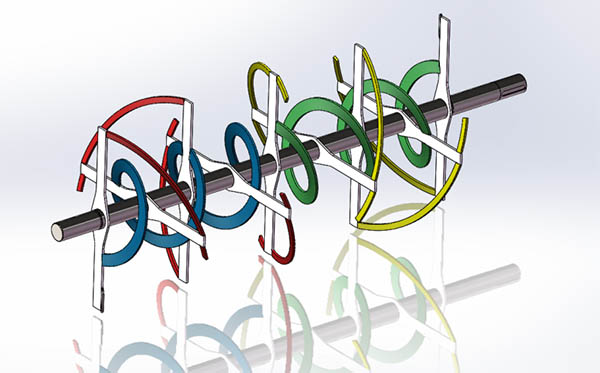

How does powder mixing machine work?

Outer ribbon displace the powder from the end to the center and inner ribbon move the powder from the center to the ends, this counter-current action results in homogeneous mixing.

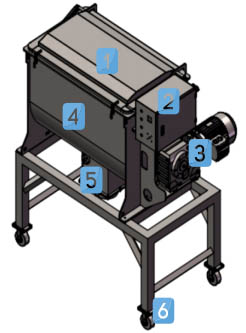

Ribbon mixing machine constituent part

Consist of

1. Mixer Cover

2. Electric Cabinet & Control Panel

3. Motor & Gearbox

4. Mixing Tank

5. Pneumatic Flap Valve

6. Frame and Mobile Casters

Key feature

■ Whole machine with full length welding;

■ Full mirror polished inside mixing tank;

■ Inside mixing tank without any removable parts;

■ Mixing uniformity up to 99%, no any mixing dead angle;

■ With patent Technology on shaft sealing;

■ Silicone ring on the lid for avoid dust come out;

■ With safety switch on the lid, safety grid on the opening for operator safety;

■ Hydraulic stay bar for easy open and close the mixer cover.

Description

Horizontal ribbon powder mixing machine is designed to mix all kinds of dry powder, some powder with little liquid and powder with small granules. It consists of one U-shaped horizontal mixing tank and two groups of mixing ribbon, driven by motor and controlled by electrical cabinet and control panel, discharged by pneumatic flap valve. The mixing uniform can reach mixing uniformity can reach 99%, one batch ribbon blender mixing time is about in 3-10 minutes, you can set the mixing time on the control panel according to your mixing request.

Details

1. The whole powder mixing machine is full welding, no any weld seam. So it's easy-cleaning after mixing.

2. Safe round corner design and silicone ring on the lid make ribbon mixing machine with good sealing to avoid no powder dust come out.

3. Whole powder mixing blender machine with SS304 material, including ribbon and shaft. Full mirror polished inside the mixing tank, it will easy cleaning after mixing.

4. The electrical accessories in the cabinet are all famous brands

5. The slightly concave flap valve at bottom center of the tank, which is completely consistent with the mixing tank, ensures no material left and no dead angle when mixing.

6. Using Germany brand Burgmann packing gland and unique shaft sealing design which applied for a patent, ensures zero leaking even mix very fine powder.

7. Hydraulic stay bar can help to easy open and close the mixer cover.

8. Safety switch, safety grid and wheels for operator safe and convenient moving.

9. English control panel is convenient for your operating.

10. Motor and gearbox can be customize according to your local electricity.

Main parameter

|

Model |

TDPM 100 |

TDPM 200 |

TDPM 300 |

TDPM 500 |

TDPM 1000 |

TDPM 1500 |

TDPM 2000 |

TDPM 3000 |

TDPM 5000 |

TDPM 10000 |

|

Capacity(L) |

100 |

200 |

300 |

500 |

1000 |

1500 |

2000 |

3000 |

5000 |

10000 |

|

Volume(L) |

140 |

280 |

420 |

710 |

1420 |

1800 |

2600 |

3800 |

7100 |

14000 |

|

Loading rate |

40%-70% |

|||||||||

|

Length(mm) |

1050 |

1370 |

1550 |

1773 |

2394 |

2715 |

3080 |

3744 |

4000 |

5515 |

|

Width(mm) |

700 |

834 |

970 |

1100 |

1320 |

1397 |

1625 |

1330 |

1500 |

1768 |

|

Height(mm) |

1440 |

1647 |

1655 |

1855 |

2187 |

2313 |

2453 |

2718 |

1750 |

2400 |

|

Weight(kg) |

180 |

250 |

350 |

500 |

700 |

1000 |

1300 |

1600 |

2100 |

2700 |

|

Total Power (KW) |

3 |

4 |

5.5 |

7.5 |

11 |

15 |

18.5 |

22 |

45 |

75 |

Accessories brand

|

No. |

Name |

Country |

Brand |

|

1 |

Stainless steel |

China |

China |

|

2 |

Circuit breaker |

France |

Schneider |

|

3 |

Emergency switch |

France |

Schneider |

|

4 |

Switch |

France |

Schneider |

|

5 |

Contactor |

France |

Schneider |

|

6 |

Assist contactor |

France |

Schneider |

|

7 |

Heat relay |

Japan |

Omron |

|

8 |

Relay |

Japan |

Omron |

|

9 |

Timer relay |

Japan |

Omron |

Customizable configuration

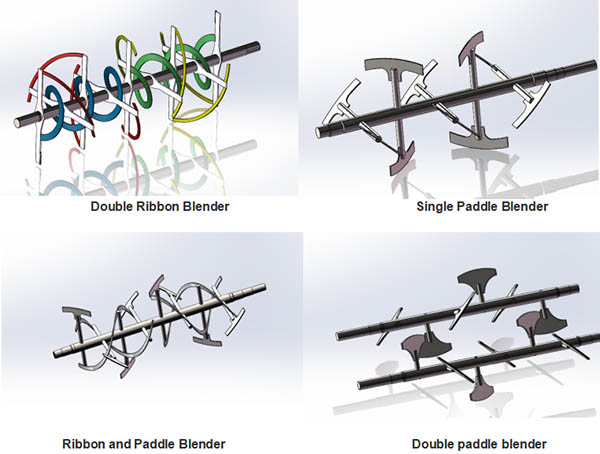

A. Optional Stirrer

Customize mixing stirrer according to different using situation and product situation: double ribbon,double paddle, single paddle, ribbon and paddle combination. As long as let us know your detailed information, then we can give you perfect solution.

B: Flexible material selection

Blender material options: SS304 and SS316L. SS304 material is more apply to food industry, and SS316 material apply for pharmaceutical industry mostly. And the two materials can be used in combination, such as touch material parts use SS316 material, other parts use SS304, for example, to mix salt, SS316 material can resist corrosion.

The surface treatment of stainless steel, including coated teflon, wire drawing, polishing and mirror polishing, can be used in different powder mixing equipment parts.

Powder Mixing Machine material selection: parts in contact with materials and parts not in contact with materials; Inside the mixer can also be targeted to increase such as anti-corrosion, anti-bonding, isolation, wear resistance and other functional coating or protective layer; The surface treatment of stainless steel can be divided into sandblasting, drawing, polishing, mirror and other treatment methods, and can be applied to different parts of use.

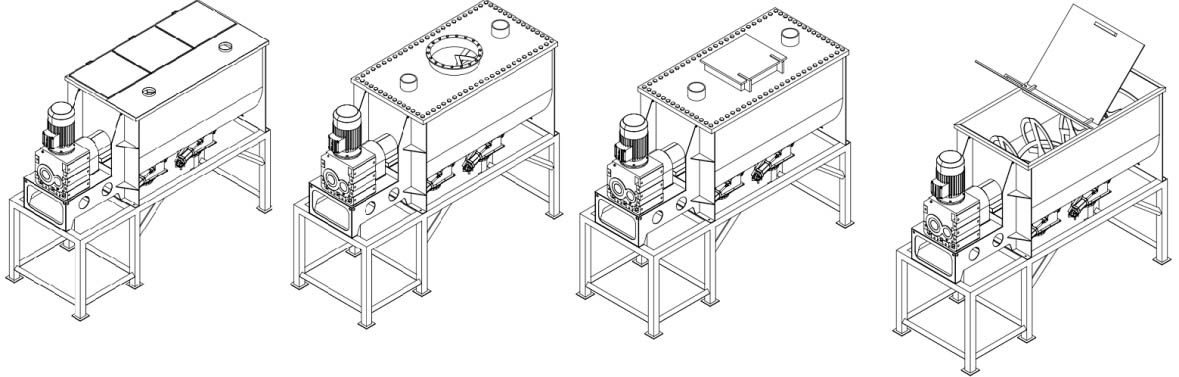

C: Various different inlets

The mixing tank top lid design of powder mixing blender machine can be customized according to customer’s requirement. The design can meet different working conditions, cleaning doors, feeding ports, exhaust ports and dust removal ports can be set according to the opening function. On the top of mixer, under of the lid, there is a safety net, it can avoid some hard impurities drop into the mixing tank and it can protect operator safe. If you need manual load the mixer, we can customize whole lid opening to convenient manual loading. We can meet your all customized requirements.

D: Excellent discharge valve

The powder mixing equipment valve can choose manual type or pneumatic type. Optional valves: cylinder valve, butterfly valve, knife valve, slip valve etc. Flap valve and barrel fit perfectly, so it don’t have any mixing dead angle. For other valves, there is a small amount of material can not be mixed connected section between the valve and the mixing tank. Some customers don’t request install discharge valve, only need us to make a flange on the discharge hole, when the customer receive the blender, they install their discharge valve. If you’re dealer, we also can customize the discharge valve for your unique design.

E: Customized additional function

Ribbon mixing machine sometimes needs to be equipped additional functions because of customer requirements, like jacket system for heating and cooling function, weighing system to know loading weight, dust removal system for avoid dust come into working environment, spraying system to add liquid material and so on.

Optional

A: Adjustable speed by VFD

Powder Mixing Machine can be customized into speed adjustable by installing a frequency converter, which can be Delta brand, Schneider brand and other requested brand. There is a rotary knob on the control panel to adjust the speed easily.

And we can customize your local voltage for the ribbon mixer, customize the motor or use VFD to transfer the voltage to meet your voltages requirements.

B: Loading system

In order to make the operation of food powder mixing machine more convenient. Usually small model mixer, such as 100L, 200L, 300L 500L, to equip with stairs to loading, larger model mixer, such as 1000L,1500L, 2000L 3000L and other larger customize volume mixer, to equip with working platform with steps, they are two kinds of manual loading methods. As to automatic loading methods, there are three kinds of methods, use screw feeder to load powder material, bucket elevator for granules loading are all available, or vacuum feeder to load powder and granules product automatically.

C: Production line

Coffee Powder Mixing Blender Machine can works with screw conveyor, storage hopper, auger filler or vertical packing machine or given packing machine, capping machine and labeling machine to form production lines to pack powder or granules product into bags/jars. The whole line will connect by flexible silicone tube and won't have any dust come out, keep the dust-free working environment.

Factory showroom

Shanghai Tops Group Co., Ltd. (www.topspacking.com) is professional manufacturer of mixing machine for more than ten years in Shanghai. We specialize in the fields of designing, manufacturing, supporting and servicing a complete production line of machinery for different kinds of powder and granular products, our main target of working is to offer the products which are related to the food industry, agriculture industry, chemical industry, and pharmacy field and more. We value our customers and are dedicated to maintaining relationships to ensure continued satisfaction and create win-win relationship.

FAQ

1. Are you a food powder mixing machine manufacturer?

Of course, Shanghai Tops Group Co., Ltd. is one of the leading powder mixing equipment in China, who has been in packing machine industry for more than ten years, packing machine and powder mixing machine are both main production. We have sold our machines to more than 80 countries all over the world and got good feedback from end-user, dealers.

Moreover, our company has a number of invention patents of powder mixing machine design as well other machines.

We have abilities of designing, manufacturing as well customizing a single machine or whole packing production line.

2.How long does the ribbon mixing machine lead time?

For standard model powder mixing machine, the lead time is 10-15days after receiving your down payment. As to customized mixer, the lead time is about 20 days upon receiving your deposit. Such as customize motor, customize additional function, etc. If your order is urgent, we can delivery it in one week upon work overtime.

3. What about your company service?

We Tops Group focus on service in order to provide a optimal solution to customers including before-sales service and after-sales service. We have stock machine in showroom for making test to help customer make final decision. And we also have agent in Europe, you can make a testing in our agent site. If you place order from our Europe agent, you also can get after-sale service in your local. We always care about your mixer running and after-sales service is always at your side to ensure everything runs perfectly with guaranteed quality and performance.

Regarding after-sales service, if you place order from Shanghai Tops Group, within one year’s warranty, if the ribbon mixing machine have any problem, we will free send the parts for replacement, including express fee. After warranty, if you need any spare parts, we will give you the parts with cost price. In case of your mixer fault happening, we will help you to deal with it in first time, to send picture/video for guidance, or live online video with our engineer for instruction.

4. Do you have the ability of design and propose solution?

Of course, we have professional design team and experienced engineer. For example, we designed a bread formula production line for Singapore BreadTalk.

5. Does your powder mixing blender machine have CE certificate?

Yes, we have powder mixing equipment CE certificate. And not only coffee powder mixing machine, all our machines have CE certificate.

Moreover, we have some technical patents of powder ribbon blender designs, such as shaft sealing design, as well auger filler and other machines appearance design, dust-proof design.

6. What products can food powder mixing machine handle?

powder mixing machine can mix all kinds of powder or granule products and a small amount of liquid, and widely applied in food, pharmaceuticals, chemical and so on.

Food industry: all kinds of food powder or granule mix like flour, oat flour, whey protein powder, curcuma powder, garlic powder, paprika, seasoning salt, pepper, pet food, paprika, jelly powder, ginger paste, garlic paste, tomato powder, flavours and fragrances, museli etc.

Pharmaceuticals industry: all kinds of medical powder or granule mix like aspirin powder, ibuprofen powder, cephalosporin powder, amoxicillin powder, penicillin powder, clindamycin powder, domperidone powder, calcium gluconate powder, amino acid powder, acetaminophen powder, herb medicine powder, alkaloid etc.

Chemical industry: all kinds of skin care and cosmetics powder or industry powder mix, like pressed powder, face powder, pigment, eye shadow powder, cheek powder, glitter powder, highlighting powder, baby powder, talcum powder, iron powder, soda ash, calcium carbonate powder, plastic particle, polyethylene, epoxy powder coating, ceramic fiber, ceramic powder, latex powder, nylon powder etc.

Click here to check if your product can works on ribbon powder mixing machine

7. How do powder mixing blender machine work when I receive it?

To pour your product into the mixing tank, and then connect power, to set the ribbon blender mixing time on the control panel, final to press "on" to let the mixer working. When mixer run at the time you set, the mixer will stop working. Then you rotate discharge switch to point "on", discharge valve open it for discharge product. One batch mixing is done (If your product does not flow very well, you will need to turn on the mixing machine again and let the Lot run to push the material out quickly). If you continue mix the same product, you don't need clean the powder mixing machine. Once you change another product for mixing, you need clean the mixing tank. If you want to use water to wash it, you need move the powder mixing equipment to outside or headwaters, I suggest that you use water torch to wash it and then to use air gun to dry it. Because the inside of mixing tank is mirror polishing, the product material is easy to clean by water.

And the operation manual will come with machine, and electronic file manual will be send you by email. In fact, the powder mixing machine operation is very simple, don’t need any adjusting, only connect power and turn on switches.

8.What's the powder mixing machine price?

For our powder mixing equipment, the standard model is from 100L to 3000L (100L, 200L, 300L, 500L, 1000L, 1500L, 2000L, 3000L), as to more larger volume, it need customize. So our sales staff can quote you immediately when you ask for standard model blender. For customized larger volume ribbon mixer, the price need calculated by engineer, and then to quote you. You only advise your mixing capacity or detailed model, then our salesperson can give you the price right now.

9. Where to find a powder mixing equipment for sale near me?

So far we have a sole agent in Spain of Europe, if you want to purchase the blender, you can contact our agent, you purchase the blender from our agent, you can enjoy the after-sales in your local, but price is higher than us (Shanghai Tops Group Co., Ltd.), after all, our agent need deal with sea freight, customs clearance and tariffs and after-sales cost. If you purchase food powder mixing machine from us(Shanghai Tops Group Co.,Ltd), our sales staff also can serve you well, every sales person is trained, so they are familiar with the machine knowledge, 24 hours a day online, service at any time. If you doubt with our mixing machine quality and query our service, we can supply our cooperated clients information to you as a reference, on condition that we need get the agree from this client. So you can consult our cooperated client regarding quality and service, pls be assured to purchase our mixing machine.

If you want to act as our agent in other areas as well, we'd welcome to have you on board. We will give big support to our agent. Are you interested in?