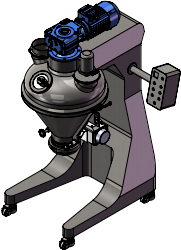

General Description

Vertical Ribbon Blender

TP-VM Series

The vertical ribbon mixer comprises a single ribbon shaft, a vertically-shaped vessel, a drive unit, a cleanout door, and a chopper. It is a newly developed mixer that has gained popularity in the food and pharmaceutical industries due to its simple structure, easy cleaning, and complete discharge capabilities. The ribbon agitator elevates the material from the bottom of the mixer and allows it to descend under the influence of gravity. Additionally, a chopper is situated on the side of the vessel to disintegrate agglomerates during the mixing process. The cleanout door on the side facilitates thorough cleaning of all areas within the mixer. Because all components of the drive unit are situated outside of the mixer, the possibility of oil leakage into the mixer is eliminated.

Application

Main Features

● There are no dead angles at the bottom, ensuring a uniform mixture without any dead angles.

● The small gap between the stirring device and the copper wall effectively prevents material adhesion.

● The highly sealed design ensures a uniform spray effect, and the products adhere to GMP standards.

● Utilizing internal stress relief technology results in stable system operation and reduced maintenance costs.

● Equipped with automatic operation timing, overload protection, feeding limit alarms, and other functions.

● Incorporated interrupted wire rod anti-sport design enhances mixing uniformity and reduces mixing time.

Specification

| Model | TP-VM-100 | TP-VM-500 | TP-VM-1000 | TP-VM-2000 |

| Full Volume (L) | 100 | 500 | 1000 | 2000 |

| Working Volume (L) | 70 | 400 | 700 | 1400 |

| Loading Rate | 40-70% | 40-70% | 40-70% | 40-70% |

| Length(mm) | 952 | 1267 | 1860 | 2263 |

| Width(mm) | 1036 | 1000 | 1409 | 1689 |

| Height(mm) | 1740 | 1790 | 2724 | 3091 |

| Weight(kg) | 250 | 1000 | 1500 | 3000 |

| Total Power (KW) | 3 | 4 | 11.75 | 23.1 |

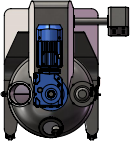

Detailed Photos

1.Constructed entirely from 304 stainless steel (316 available upon request), the blender features a fully mirror-polished interior within the mixing tank, including the ribbon and shaft. All components are meticulously joined through full welding, ensuring there is no residual powder, and facilitating easy cleaning after the mixing process.

2.Top cover equipped with an inspectionport and a light.

3.Spacious inspection door for effortless cleaning.

4.Separate electrical control box with an inverter for adjustable speed.

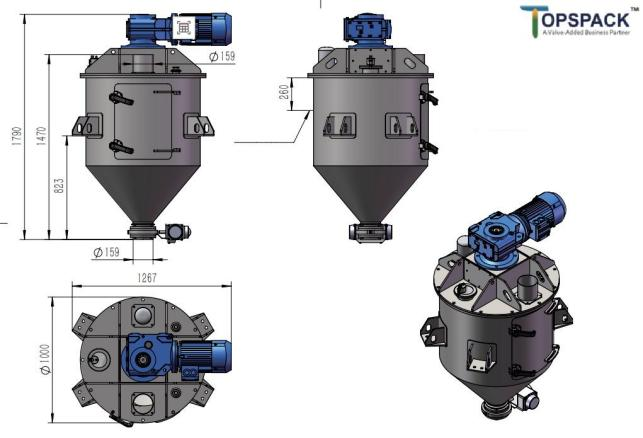

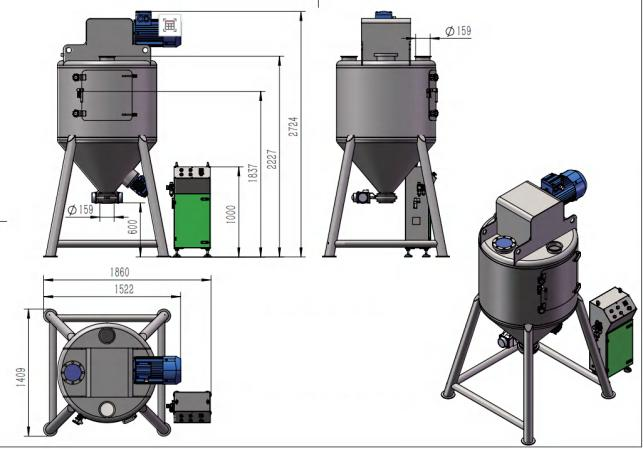

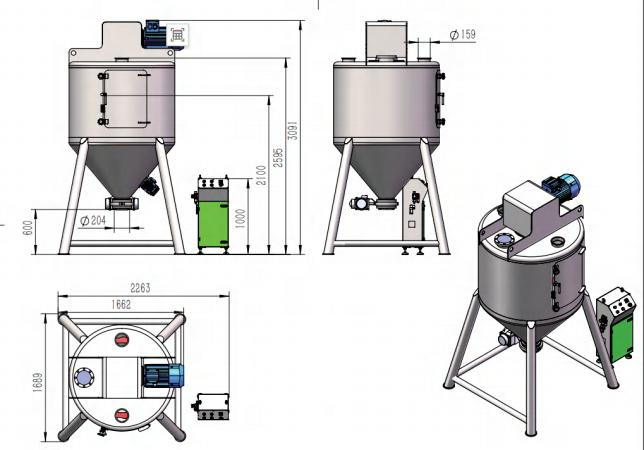

Drawing

Design parameters for a 500L vertical ribbon mixer:

1. Designed total capacity: 500L

2. Designed power: 4kw

3. Theoretical effective volume: 400L

4. Theoretical rotational speed: 0-20r/min

Design parameters for a 1000L vertical mixer:

1. Theoretical total power: 11.75kw

2. Total capacity: 1000L Effective volume: 700L

3. Designed maximum speed: 60r/min

4. Suitable air supply pressure: 0.6-0.8MPa

Design parameters for a 2000L vertical mixer:

1. Theoretical total power: 23.1kw

2. Total capacity: 2000L

Effective volume: 1400L

3. Designed maximum speed: 60r/min

4. Suitable air supply pressure: 0.6-0.8MPa

TP-V200 Mixer

Design parameters for a 100L vertical ribbon mixer:

1. Total capacity:100L

2. Theoretical effective volume: 70L

3. Main motor power: 3kw

4. Designed speed: 0-144rpm (adjustable)

CERTIFICATES