General Description

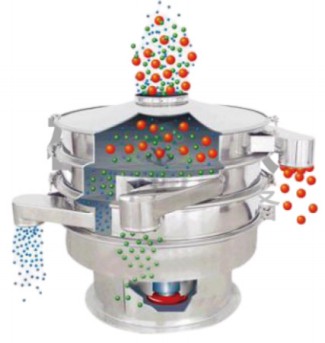

VIBRATING SIEVE

TP-ZS Series

The TP-ZS series vibrated filter is a type of precision powder griddle, characterized by low noise, high efficiency, and a quick 2-3 minute griddle replacement. Its fully enclosed structure makes it ideal for filtering particles and powder.

Broadly speaking, this equipment serves as a filtration mechanical separation device used for treating solid phases in slurry. It consists of a screen and a vibrator.

The coarseness of the screen is indicated by mesh size, with screens below 50 mesh considered coarse screens and those above 80 mesh considered fine screens.

Application

Features

● High efficiency and refined design ensure durability, making it suitable for any powders and liquids.

● Easy to replace the mesh, simple operation, and convenient cleaning.

● The mesh holes never get clogged.

● Automatically discharges impurities and coarse materials, allowing continuous operation.

● Unique mesh frame design extends the mesh's lifespan, with replacement needed only every 3-5 cycles.

● Compact size and easy to move.

● The griddle can have up to 5 layers, though 3 layers are recommended.

Specifications

| Model | TP-KSZP- 400 | TP-KSZP- 600 | TP-KSZP- 800 | TP-KSZP- 1000 | TP-KSZP- 1200 | TP-KSZP- 1500 | TP-KSZP- 1800 | TP-KSZP- 2000 |

| Diameter(mm) | Φ400 | Φ600 | Φ800 | Φ1000 | Φ1200 | Φ1500 | Φ1800 | Φ2000 |

| Effective area(m2) | 0.13 | 0.24 | 0.45 | 0.67 | 1.0 | 1.6 | 2.43 | 3.01 |

| Mesh | 2-400 | |||||||

| Material size(mm) | <Φ10 | <Φ10 | <Φ15 | <Φ20 | <Φ20 | <Φ20 | <Φ30 | <Φ30 |

| Frequency(rpm) | 1500 | |||||||

| Power(Kw) | 0.2 | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 3 | 3 |

| Height to 1st layer | 605 | 605 | 730 | 810 | 970 | 1000 | 1530 | 1725 |

| Height to 2nd layer | 705 | 705 | 860 | 940 | 1110 | 1150 | 1710 | 1905 |

| Height to 3rd layer | 805 | 805 | 990 | 1070 | 1250 | 1300 | 1890 | 2085 |

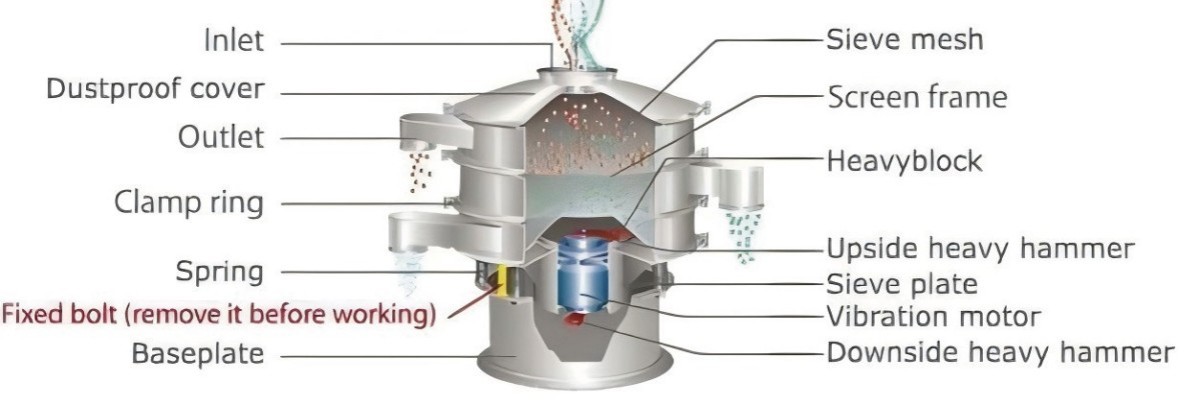

Structure Drawing

Mesh Size Reference Table

|

British (mesh) |

American (mesh) |

Tyler (mesh) |

International

standard sieve (mesh) |

Micron

comparison |

Millimeter

comparison |

| 4 | 5 | 5 | —— | 4000 | 4.00 |

| 6 | 7 | 7 | 280 | 2812 | 2.81 |

| 8 | 10 | 9 | 200 | 2057 | 2.05 |

| 10 | 12 | 10 | 170 | 1680 | 1.68 |

| 12 | 14 | 12 | 150 | 1405 | 1.40 |

| 14 | 16 | 14 | 120 | 1240 | 1.20 |

| 16 | 18 | 16 | 100 | 1003 | 1.00 |

| 18 | 20 | 20 | 85 | 850 | 0.85 |

| 22 | 25 | 24 | 70 | 710 | 0.71 |

| 30 | 35 | 32 | 50 | 500 | 0.50 |

| 36 | 40 | 35 | 40 | 420 | 0.42 |

| 44 | 45 | 42 | 35 | 355 | 0.35 |

| 52 | 50 | 48 | 30 | 300 | 0.30 |

| 60 | 60 | 60 | 25 | 250 | 0.25 |

| 72 | 70 | 65 | 20 | 210 | 0.21 |

| 85 | 80 | 80 | 18 | 180 | 0.18 |

| 100 | 100 | 100 | 15 | 150 | 0.15 |

| 120 | 120 | 115 | 12 | 125 | 0.12 |

| 150 | 140 | 150 | 10 | 105 | 0.10 |

| 170 | 170 | 170 | 9 | 90 | 0.09 |

| 200 | 200 | 200 | 8 | 75 | 0.075 |

| 240 | 230 | 250 | 6 | 63 | 0.063 |

| 300 | 270 | 270 | 5 | 53 | 0.053 |

| 350 | 325 | 325 | 4 | 45 | 0.045 |

| 400 | 400 | 400 | —— | 37 | 0.037 |

| 500 | 500 | 500 | —— | 25 | 0.025 |

| 625 | 625 | 625 | —— | 20 | 0.020 |

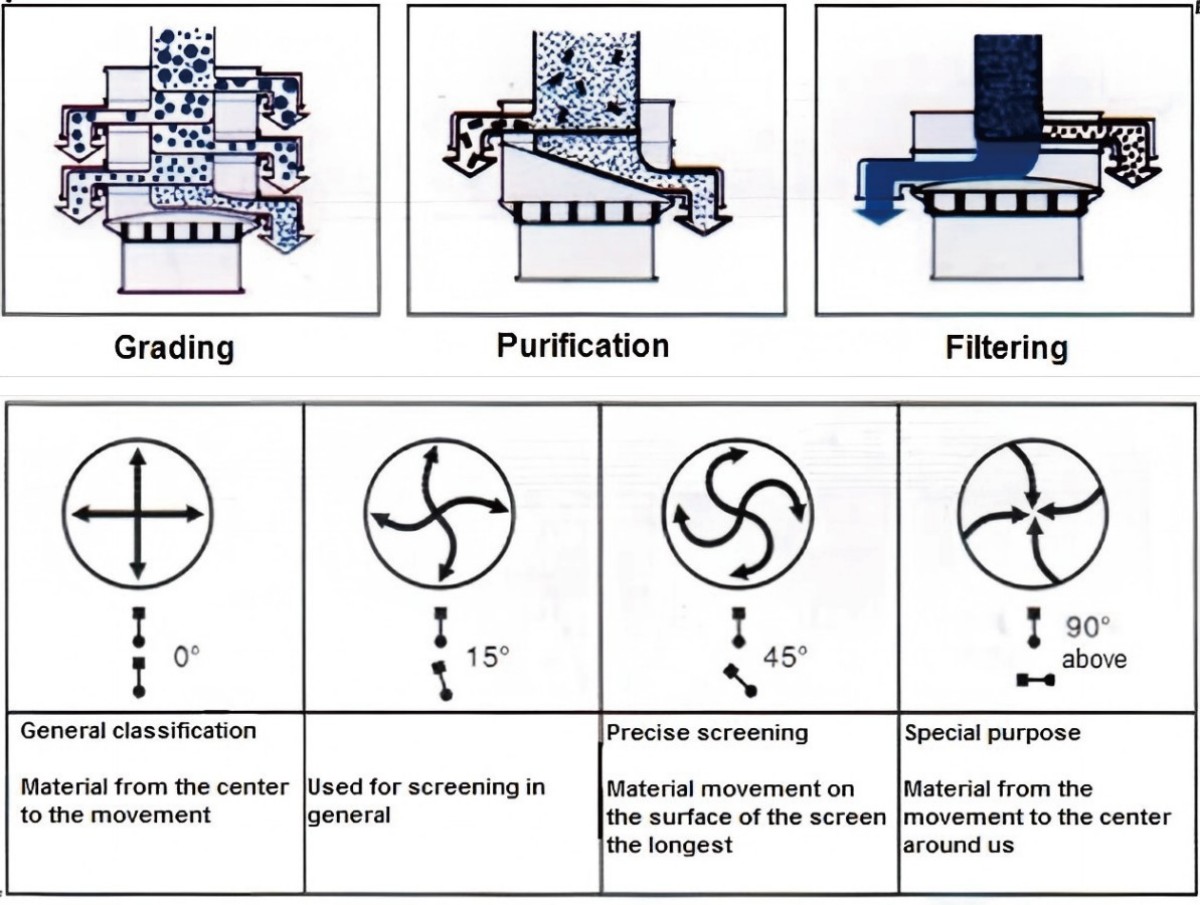

Work Principle

The ZS series vibrating griddle operates by using an upright motor as the vibration source. Eccentric hammers are mounted on both the top and bottom of the motor, which convert rotational movement into horizontal, vertical, and inclined motions.

These combined movements are then transferred to the griddle's surface. By adjusting the phase angles on both the top and bottom, you can alter the movement patterns of the griddle surface.

Essentially, the operation relies on the interplay of vibrational force and the screening action of the griddle.

Common Classification

It can be divided into Straight discharge vibrating sieve and rotary discharge vibrating sieve.

Details

Domical Vault

Eliminates the need for reinforcement ribs, making the lid stronger and easier to clean.

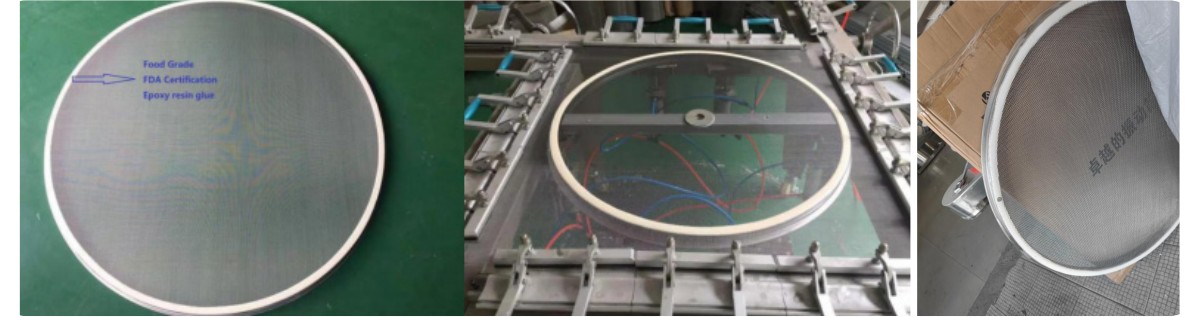

New Design Mesh Screen

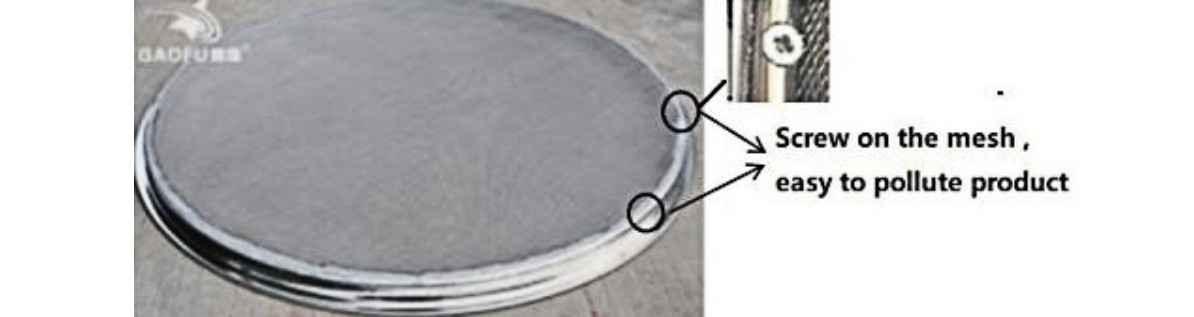

The mesh screen and mesh screen ring are bonded together with food-grade epoxy resin, making it easy to change the mesh size and clean.

Note: The standard design of the mesh screen uses screws to attach it to the screen ring, which makes changing the mesh size more difficult and poses a risk of contamination from hidden screws.

Sealing Features

The sealing ring and epoxy resin will hide in the interlayer, without leakage and material hiding.

Quick-Release Seal: Allows for quick and easy disassembly, making cleaning simpler.

Other Details

● Both cover and inlet are finely polished and welding.

● Round and silicone bouncing cleaning ring and gasket.