Product Description

The double shaft paddle mixer, also known as a no gravity mixer, is extensively utilized for blending dry powders, granules, and small amounts of liquid in the food, chemical, pesticide, animal feed, and battery industries.

Working Principle

1. Double shaft paddle mixer is with 2 horizontal paddle shaft; there is the paddle on each shaft;

2. With the driven equipment, two cross paddle shafts moves intersection and patho-occlusion.

3. Driven equipment makes paddle rotating fast; the rotating paddle generates centrifugal force during high speed rotation, spilling the material to the upper part in the barrel, then material falling down (the vertex of material is in a so-called instant non-gravity state). Driven by the blades, material is mixed back and forth; also sheared and separated by the meshing space between the twin shafts; fast and evenly mixed.

Product Specificaition

|

Model |

TP-DS300 |

TP-DS500 |

TP-DS1000 |

TP-DS1500 |

TP-DS2000 |

TP-DS3000 |

|

Effective volume(L) |

300 |

500 |

1000 |

1500 |

2000 |

3000 |

|

Full volume(L) |

420 |

650 |

1350 |

2000 |

2600 |

3800 |

|

Loading Ratio |

0.6-0.8 |

|||||

|

Turning speed(rpm) |

53 |

53 |

45 |

45 |

39 |

39 |

| power |

5.5 |

7.5 |

11 |

15 |

18.5 |

22 |

|

Total weight(kg) |

660 |

900 |

1380 |

1850 |

2350 |

2900 |

|

Total size |

1330*1130*1030 |

1480*1350*1220 |

1730*1590*1380 |

2030*1740*1480 |

2120*2000*1630 |

2420*2300*1780 |

|

R(mm) |

277 |

307 |

377 |

450 |

485 |

534 |

| Power supply |

3P AC208-415V 50/60Hz |

|||||

Product Features

1. High active :Rotate reversely and throw materials to different angles,mixing time 1-3min.

2. High uniformity:Compact design and rotated shafts be filled with hopper, mixing uniformity up to 99%.

3. Low residue:Only 2-5mm gap between shafts and wall, open-type discharging hole.

4. Zero leakage: Patent design and ensure the rotating axle & discharging hole zero leakage.

5. Full clean:Full weld and polishing process for mixing hopper, w/o any fastening piece like screw,nut.

6. Nice profile: the whole machine is made by 100% stainless steel to make its profile elegant except bearing seat.

Details

Configuration

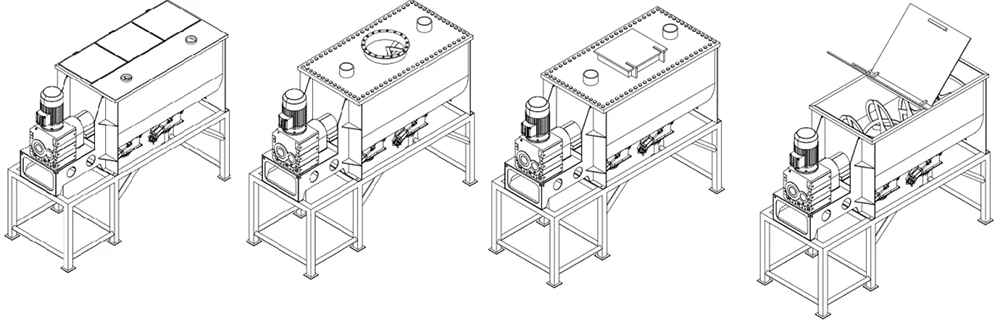

A: Flexible material selection

Material can be carbon steel, manganese steel, ss304, 316L and Carbon steel; besides, different Material can also be used in combination. Surface treatment for stainless steel include sandblasting, wiredrawing, polishing, mirror polishing, all can be used in different parts of a mixer.

B: Various Inlets

Various inlets on the top cover of the barrel can be designed according to different situations. They can be used as man hole, cleaning door, feeding hole, vent, and dust colleting hole. The top cover can be designed as fully-opened lid for easy cleaning.

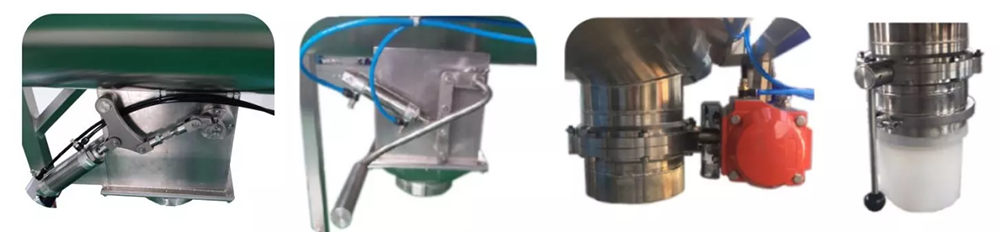

C: Excellent discharging unit

The drive types of valve are Manual, pneumatic, and electric.

Valves for consideration: powder spherical valve, cylinder valve, plum-blossom dislocation valve, butterfly valve, rotary valve etc.

D:Selectable Function

Paddle blender sometimes needs to be equipped additional functions because of customer requirements, like jacket system for heating and cooling, weighing system, dust removal system, spray system and so on.

E: Adjustable speed

Powder ribbon blender machine can be customized into speed adjustable by installing a frequency converter. And for motor and reducer,it can change the motor brand, customize the speed, increase the power, add the motor cover.

Our Certifications

About Us

Shanghai Tops Group Co., Ltd. Which is a professional enterprise of designing, manufacturing, selling powder pellet packaging machinery and taking over complete sets of engineering.With the continuously explore, research and application of advanced technology, the company is developing, and have a innovative team composed of professional and technical personnel, engineers, sales and after-sales service people.Since the company founded, it has successfully developed several series, dozens of varieties of packaging machinery and equipment, all the products meet the GMP requirements.

Our machines are widely used in variety industries of food, agriculture ,industry, pharmaceticals and chemicals, etc. With many years’ development, we have built our own technician team with innovative technicians and marketing elites, and we sucessfully develop many advancedd products as well as help customer design series of package production lines. Our machines are all strictly comply with the National Food Safety Standard, and machines have CE certificate.

We are struggling to be the“first leader”among the same range of fileds of packaging machinery. On the way to success, we need your utmost support and ccooperation. Let’s work hard altogether and make much greater success!

Our Service:

1) Professional advice and rich experience help to choose machine.

2) Lifelong maintainance and considerate technical support

3) Technicians can be sent to abroad to install.

4) Any problem before or after delivery, you could find and talk with us anytime.

5) Video / CD of test running and installation, Maunal book, tool box sent with machine.

FAQ

1.Are you a ribbon blender manufacturer?

Shanghai Tops Group Co., Ltd is one of the leading ribbon blender manufacturers in China, who has been in packing machine industry for over ten years.

2.Does your powder ribbon blender have CE certificate?

Not only the powder ribbon blender but also all our machines have CE certificate.

3.How long is the ribbon blender delivery time?

It takes 7-10 days to produce a standard model. For customized machine, your machine can be done in 30-45 days.

4.What’s your company service and warranty?

■TWO YEAR warranty, ENGINE THREE YEARS warranty, life-long service (Warranty service will be honored if the damage is not caused by human or improper operation)

■Provide accessory parts in favorable price

■Update configuration and program regularly

■Respond to any question in 24 hours Site service or online video service

For the payment term, you can choose from following terms: L/C, D/A, D/P, T/T, Western Union, Money Gram, Paypal

For the shipping, we accept all term in contract like EXW, FOB, CIF, DDU etc.

5.Do you have the ability of design and propose solution?

Of course, we have professional design team and experienced engineer. For example, we designed a bread formula production line for Singapore BreadTalk.

6.What products can ribbon blender mixer handle?

It is used for mixing powders, powder with liquid and powder with granule and even the smallest quantity of ingredient can be blended efficiently with large volumes. Ribbon mixing machines are also useful for agricultural chemicals, food, pharmaceuticals, etc. Ribbon mixing machine offers highly uniformity mixing for efficient process and result.

7. How do industry ribbon blenders work?

Double layer ribbons which stand and turn in opposite angels to form a convection in different materials so that it can reach a high mixing efficiency. Our special design ribbons can achieve no dead angle in mixing tank.

The effective mixing time is only 5-10 minutes, even less within 3 min.

8.How to select a double ribbon blender?

Choose a suitable model

Ribbon blenders have the effective mixing volume. Normally it is about 70%. However, some suppliers name their models as total mixing volume, while some like us name our ribbon blender models as effective mixing volume. You need to calculate the suitable volume according to your product density and batch weight. For example, manufacturer TP produces 500kg flour each batch, whose density is 0.5kg/L. The output will be 1000L each batch. What TP needs is a 1000L capacity ribbon blender. And TDPM 1000 model is suitable.

Ribbon blender quality

Shaft sealing:

test with water shows the shaft sealing effect. Powder leakage from shaft sealing always troubles users.

Discharge sealing:

test with water also shows the discharge sealing effect. Many users have met leakage from discharge.

Full-welding:

Full welding is one of the most important part for food and pharmaceutical machines. Powder is easy to hide in gap, which may pollute fresh powder if residual powder goes bad. But full-welding and polish can make no gap between hardware connection, which can show machine quality and usage experience.

Easy-cleaning design:

A easy-cleaning ribbon blender will save much time and energy for you which is equal to cost.