1. Cap Elevator and cap placement system installation

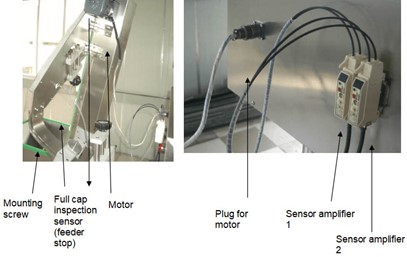

Cap arrangement and detection sensor installation

Before shipping, the cap elevator and placement system are detached; please install the cap organizing and placing system on the capping machine before running it. Please connect the system as shown in the images below:

Lack of cap inspection sensor (machine stop)

a. With a mounting screw, connect the cap, putting the track and ramp together.

b. Connect the motor wire to the plug on the control panel’s right side.

c. Connect the sensor amplifier 1 to the full-cap inspection sensor.

d. Connect the sensor amplifier 2 to the lack cap inspection sensor.

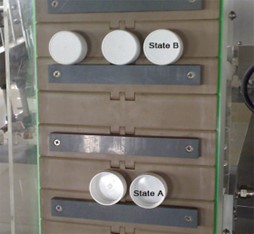

Adjust the angle of the cap climbing chain: Before shipment, the angle of the cap climbing chain was modified based on the sample cap you presented. If the specifications of the cap must be changed (just the size, not the type of cap), please adjust the angle of the cap climbing chain using the angle adjusting screw until the chain can only convey caps that lean on the chain on the top side. The following indications:

When the cap climbing chain is bringing caps up, the cap in state A is in the correct direction.

If the chain is at the appropriate angle, the cap in state B will automatically descend into the tank.

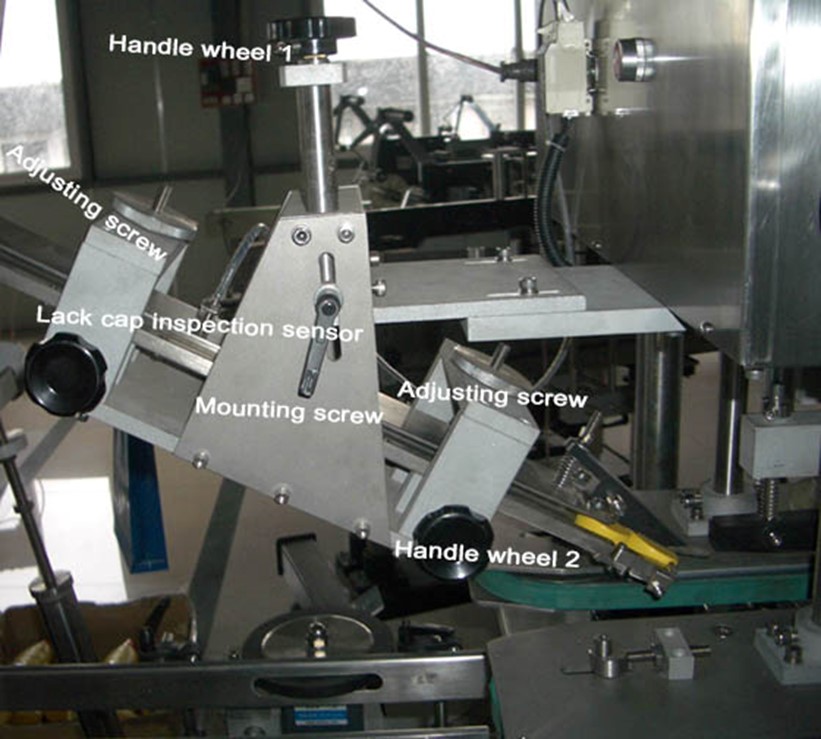

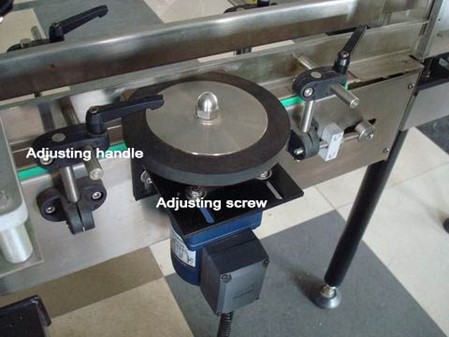

Tweak the cap dropping system (chute)

The angle of the dropping chute and the space have already been determined based on the sample provided. Normally, if there is no other new bottle or cap specification, the setting does not need to be modified. And if there are more specifications than 1 specification of bottle or cap, the client needs to list the item on the contract or its attachment to ensure the manufactory leaves enough space for further modifications. The adjusting approach is as follows:

Please unscrew the mounting screw before turning the handle wheel to adjust the height of the cap dropping system.

The adjustment screw allows you to change the height of the chute space.

The width of the chute can be adjusted using the handle wheel 2 (on both sides).

Modifying the cap pressing component

When the bottle enters the area of the cap pressing section, the cap automatically covers the bottle’s mouth from the chute. Because of the height of the bottles and caps, the cap pressing section can also be modified. If the pressure on the cap is insufficient, the capping performance will suffer. The pressing performance will be altered if the position of the cap press portion is too high. Furthermore, if the position is too low, the cap or bottle will be harmed. Normally, the height of the cap pressing component is modified before shipment. If the user needs to readjust the height, the procedure is as follows:

Before adjusting the height of the cap pressing section, please remove the mounting screw.

There is another cap pressing element with the machine to fit the tiniest bottles, and the video shows how to replace it.

Adjusting the air pressure to force the cap down the chute.

2. Changing the overall height of the primary sections.

The machine elevator can vary the height of the main parts, such as the bottle fix structure, gum-elastic spin wheel, and cap pressing portion. The machine elevator control button is located on the right side of the control panel. Before starting the machine elevator, the user should remove the mounting screws from the two support pillars.

Signifies both down and up. To ensure that the position of the spin wheels corresponds to the position of the caps. Please turn off the power and tighten the mounting screw after adjusting the elevator.

Note: Please keep pressing the lift switch (green) until you reach the desired position. The elevator’s speed is rather slow; please wait patiently.

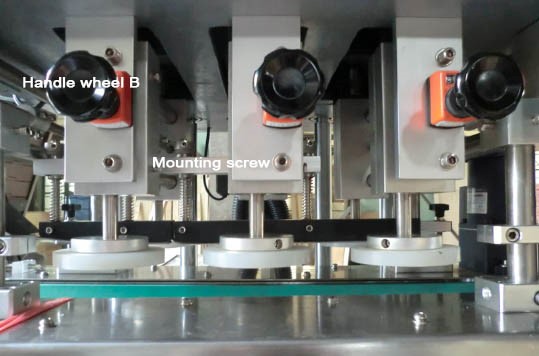

3. Adjust the spin wheel made of gum-elastic (three pairs of spin wheels).

The machine elevator adjusts the height of the spin wheel.

The width of the pair of spin wheels is varied based on the diameter of the cap.

Typically, the gap between two wheels is 2-3 mm smaller than the diameter of the cap. Handle wheel B allows the operator to change the width of the spin wheel. (Each handle wheel can adjust the relative spin wheel.)

Before adjusting the handle wheel B, please remove the mounting screw.

4. The bottle fix structure is being adjusted.

The position of the fixed structure and link axis can be modified to change the bottle’s fixed position. The bottle is easy to lay down while feeding or capping if the fixation position is too low on the bottle. On the other hand, if the fixed location is too high on the bottle, the spin wheels will not perform properly. After adjusting the conveyor and bottle fix structures, double-check that the centerlines are on the same line.

Adjust the distance between bottle fasten belts by turning handle wheel A (by turning the handle with two hands together). As a result, the structure could effectively fix the bottle throughout the pressing process.

The machine elevator usually adjusts the height of the bottle-fixing belt.

(Warning: After loosening the mounting screw on the 4-link shaft, the operator can vary the height of the bottle fix belt in a microscope.)

If the operator must move the belt in a large range, loosen screws 1 and 2 combined and turn the adjustment knob; if the operator needs to modify the height of the belt in a limited range, loosen screw 1 only and crank the adjustment knob.

5. Modifying the bottle space with the adjustment wheel and railing.

When changing the bottle specification, the operator should adjust the wheel and railing to modify the location of the bottle space. The distance between the space adjustment wheel and the railing should be 2-3 mm smaller than the bottle’s diameter. After adjusting the conveyor and bottle fix structures, double-check that the centerlines are on the same line.

Adjust the position of the bottle space adjusting wheel by loosening the adjusting screw.

The width of the handrail on both sides of the conveyor can be adjusted using the loose adjustment handle.

Post time: Jun-07-2022