Selecting the right Powder Blender for food manufacturing requires careful consideration of your production needs. Manufacturers often face challenges such as air incorporation, foaming, lumping, and clogging during mixing. Matching the blender’s capabilities to your requirements helps prevent these issues and ensures consistent quality. TOPSGROUP, with over 20 years of experience, offers innovative solutions and a wide product range that adapts to various industry demands.

Key Takeaways

• Assess your manufacturing needs carefully. Understand the properties of your powders to select the right blender that prevents issues like clumping and uneven mixing.

• Choose the right batch size for your blender. Ensure the design matches your production volume to achieve a consistent and homogeneous mix.

• Prioritize hygiene standards. Select blenders that meet food safety regulations to protect product quality and consumer health.

• Look for features that enhance mixing efficiency. Modern blenders can mix quickly and handle various powders, reducing waste and improving product quality.

• Evaluate suppliers based on quality assurance, technical support, and customization options. A reliable supplier can significantly impact your production success.

Assess Manufacturing Needs

Product Types

Food manufacturing relies on powders with different physical and chemical properties. These properties affect how powders flow, mix, and reconstitute. For example, powders with high hydrophobicity or small particle size may take longer to wet and dissolve. The content of proteins and lipids also impacts mixing and reconstitution times. Understanding these factors helps manufacturers choose the right Powder Blender for their process. Poor flowability can cause clumping and uneven discharge, which disrupts production. Strategies to improve flow include granulation, reducing moisture, adding flow aids, and optimizing equipment design. TOPSGROUP offers solutions for a wide range of powder types, from free-flowing to cohesive materials, ensuring efficient mixing and consistent results.

• Cohesion and adhesion between particles depend on forces like Van der Waals and electrostatic attraction.

• Tumble blenders work well for fragile, free-flowing powders.

• Paddle blenders and high-shear mixers handle sticky or cohesive powders.

Batch Size

Batch size is a key factor in selecting a blender. Food manufacturing operations often handle batches from 200 kg to 1500 kg, with some large-scale processes exceeding 2000 kg per batch. The design of the mixer must match the batch size to achieve a homogeneous mix. Larger batches may require special features to ensure uniformity. TOPSGROUP provides Powder Blender models for both small laboratory batches and large production runs.

1.Small batch blenders are ideal for R&D and pilot plants.

2.Large capacity blenders suit high-volume production.

3.Mixer design must be considered to maintain uniformity in bigger batches.

Hygiene Standards

Powder blenders in the food industry must meet strict hygiene standards. Organizations like 3-A SSI and NSF set guidelines for equipment design. These standards require blenders to eliminate retention areas, use food-safe materials, and allow easy cleaning. Compliance ensures food safety and prevents cross-contamination. TOPSGROUP designs its blenders to meet these requirements, supporting safe and sanitary production environments.

Tip: Always check that your blender meets industry hygiene standards to protect product quality and consumer health.

Powder Blender Features

Mixing Efficiency

Mixing efficiency is a key factor in food manufacturing. A Powder Blender with high mixing efficiency ensures that all ingredients are combined evenly. This leads to consistent product quality and reduces waste. Many modern blenders use advanced features to improve efficiency. For example, a double helical ribbon agitator keeps materials moving constantly inside the mixing chamber. Some blenders can finish mixing in as little as 5 to 15 minutes. They can also handle different types of powders and add small ingredients or liquids with optional spray nozzles. The table below shows how different features contribute to mixing efficiency:

|

Feature |

Contribution to Mixing Efficiency |

| Double Helical Ribbon Agitator | Ensures constant movement of materials in the mixing chamber. |

| Short Mixing Time | Achieves mixing efficiency within 5 to 15 minutes. |

| Versatile Material Handling | Handles various types of powders and small ingredient incorporation. |

| Optional Liquid Spray Nozzles | Allows for coating powders or adding liquids efficiently. |

| Heating and Cooling Jacket | Suitable for heat-sensitive materials during mixing. |

| Discharge Options | Provides fast and convenient material spillage. |

| Scalable Sizes | Available in sizes from 100 liters to 30,000 liters. |

| Customizable Construction Materials | Made from materials that meet corrosion and sanitary requirements. |

When mixing efficiency improves, manufacturers see several benefits:

• Blends become more homogeneous, which means every batch has the same quality.

• Nutritional values stay consistent.

• Less waste occurs during production, which saves money.

• Equipment maintenance can boost efficiency by up to 20%.

TOPSGROUP uses patented technologies in their Powder Blender models to achieve high uniformity and zero leakage. These features help food manufacturers maintain high standards and reliable output.

Material Compatibility

Material compatibility is important for both safety and quality. The materials used to build a Powder Blender must resist corrosion and prevent contamination. Stainless steel, especially grades SS304 and SS316, is the most common choice. It meets food-grade standards and ensures hygiene. The table below explains why stainless steel is preferred:

|

Material Type |

Description |

Purpose |

| Stainless Steel (SS304 or SS316) | Resists corrosion and contamination | Ensures hygiene and meets food-grade standards |

Choosing the right materials helps prevent product recalls. Industrial sieves also play a role in keeping powders pure and consistent. They stop clumps and moisture from affecting the product. Sieving is often a critical control point in food safety plans, especially when allergens are present. This shows how material compatibility supports both regulatory compliance and product integrity.

Cleaning & Maintenance

Easy cleaning and maintenance are essential in food manufacturing. A Powder Blender should have features that make cleaning simple and safe. Good access doors or hatches allow workers to reach all parts of the mixer. The right shaft seals reduce the chance of product buildup. Horizontal mixers are often easier to clean than vertical ones. Dry cleaning methods, such as using vacuums, brushes, or scrapers, help avoid product buildup. Safety interlocks on access doors prevent the machine from running during cleaning. The table below lists important design features:

|

Design Feature |

Description |

| Access Design | Well-designed access doors or hatches facilitate easier cleaning and maintenance. |

| Shaft Seal Selection | Choosing the right type of seal can minimize product lodging and maintenance needs. |

| Mixer Type | Horizontal mixers generally provide better access for cleaning compared to vertical mixers. |

| Cleaning Methods | Use of dry cleaning methods (vacuum, brushes, scrapers) is often preferred to avoid product buildup. |

| Safety Interlocks | Access doors should be safety interlocked to prevent operation during cleaning. |

Good maintenance can reduce downtime by up to 40%. Following food safety standards during maintenance keeps operations efficient. Using modern technology and predictive maintenance helps prevent equipment failures. Integrating food safety principles, such as HACCP, into maintenance planning is also important.

Tip: Choose a Powder Blender with sanitary design and easy-access features to save time and reduce the risk of contamination.

Automation Options

Automation is changing the way food manufacturers use Powder Blender equipment. Automatic feeding systems can handle both large and small ingredients. Programmable automation systems allow for precise control and monitoring of the production line. Automation improves worker safety and boosts operational efficiency. Here are some common automation options:

• Automatic feeding systems for both macro and micro-ingredients.

• Programmable controls for accurate monitoring and adjustment.

• Automation that enhances safety and reduces manual labor.

Automation also brings other advantages:

• It ensures precise measurement and mixing, which reduces human error.

• Workers can focus on more important tasks, lowering direct labor costs.

• Automatic batching systems make sure every batch follows the recipe exactly.

Safety Compliance

Safety compliance is a must in food manufacturing. Powder Blender equipment must meet strict safety standards. Quality assurance covers every step, from raw materials to the finished product. Staff training is important so workers can spot and fix quality issues. Food safety programs should match the product’s recipe and production process.

Manufacturers like TOPSGROUP include safety features in their designs. The table below highlights some of these features:

|

Safety Feature |

Description |

| Grounded Components | Fully grounded and conductive components to prevent static charge build-up. |

| Explosion-rated Equipment | Explosion-rated motors, sensors, and enclosures where required. |

| Dust-tight Seals | Dust-tight seals and containment designs that minimize the risk of particle escape and ignition. |

| Documentation | Comprehensive documentation and testing that demonstrate conformity with the ATEX Directive 2014/34/EU. |

Meeting these standards helps protect both workers and consumers. It also ensures that the Powder Blender operates safely and reliably in any food manufacturing environment.

Powder Blender Types

Choosing the right type of Powder Blender is essential for achieving the best results in food manufacturing. Each blender type uses a different mixing mechanism and suits specific applications.

Ribbon Blender

Ribbon blenders use a double helical ribbon agitator to move powders in multiple directions. This creates a rolling, rotating, and crossing action for rapid and uniform mixing. They are ideal for free-flowing, non-fragile materials and can handle large batch sizes. Ribbon blenders work well for dry powders, spice blends, and baking mixes.

|

Advantages |

Disadvantages |

| Multi-functional across industries | Not suitable for all laboratories |

| Swift mixing response | Ribbon agitator blockage |

| Durable and hygienic design | Longer mixing times if overfilled |

| Space-saving size | Leakage of particles if not maintained |

| Produces a homogeneous mixture | High dust control requirements |

Note: Ribbon blenders generate moderate heat due to friction and require regular maintenance to prevent leakage.

Paddle Blender

Paddle blenders use rotating paddles to gently mix ingredients. This low-shear action is perfect for fragile or heat-sensitive powders, such as chocolate, dairy powders, and coated snacks. Paddle blenders can also blend both dry and moist components, making them suitable for bakery blends and nutraceuticals.

|

Factor |

Ribbon Blender |

Paddle Mixer |

| Mixing Action | High-shear, convective | Low-shear, gentle |

| Best for Dry Powders | Free-flowing, non-fragile | Fragile, heat-sensitive |

| Mixing Speed | Fast | Moderate |

| Blend Uniformity | High for standard mixes | Excellent for sensitive mixes |

| Heat Generation | Moderate | Minimal |

| Energy Consumption | Higher | Lower |

Paddle blenders are especially effective for products that need to retain their shape, such as nuts and dried fruits.

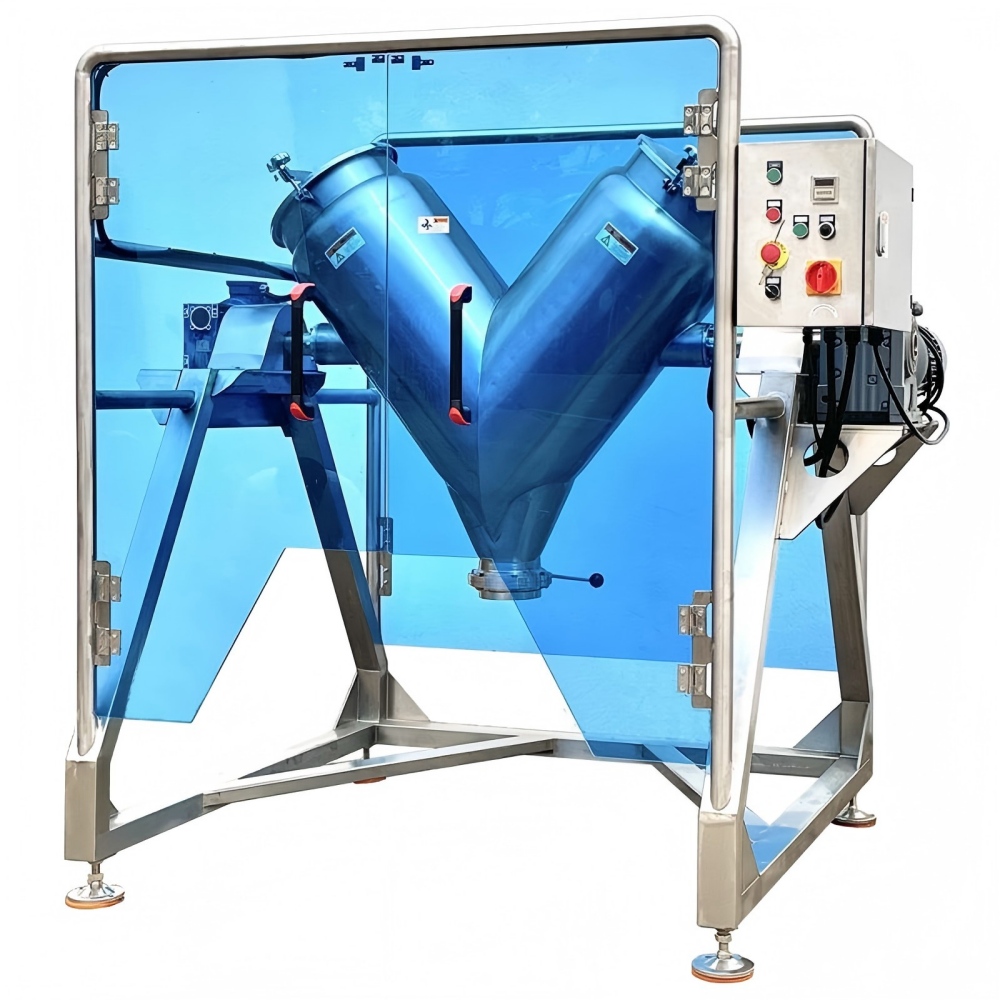

V Blender

V blenders feature a V-shaped chamber that promotes efficient blending through a tumbling effect. This design ensures gentle handling of fragile or crystalline materials, preventing damage. V blenders are made of stainless steel for hygienic food production and offer short mixing cycles.

• Gentle mixing protects delicate ingredients.

• Simple design allows for easy cleaning and maintenance.

• Adaptable with an intensifier bar for tougher materials.

V blenders are suitable for dry, free-flowing powders and are often used in the production of pharmaceuticals, spices, and specialty food powders.

Double Cone Blender

Double cone blenders use a gentle cascading motion to mix powders thoroughly without damaging fragile materials. This makes them ideal for sensitive products like cake mixes, spices, cereals, dairy powders, and nutritional supplements.

• Maintains particle integrity and aroma in spice blends.

• Prevents clumping in nutritional powders.

• Evenly disperses dry ingredients in bakery pre-mixes.

• Gently blends snack inclusions like granola and dried fruit.

Double cone blenders are also used for coffee, cocoa, baby food, and dehydrated soup preparations.

Tip: Select the blender type that matches your product’s texture and sensitivity to achieve the best results.

Supplier Evaluation

Choosing the right powder blender supplier is as important as selecting the equipment itself. A reliable supplier brings experience, innovation, and strong support to your food manufacturing process. TOPSGROUP, for example, has over two decades of expertise and a reputation for quality and service. When evaluating suppliers, focus on four key areas: quality assurance, technical support, customization, and warranty.

Quality Assurance

Quality assurance ensures that the blender meets food safety and sanitary standards. Look for suppliers who provide recognized certifications. These certifications show that the equipment is safe, easy to clean, and built for food production.

|

Certification Type |

Purpose |

| 3-A Certifications | Assures processors that equipment meets sanitary standards and provides criteria for sanitary design. |

| USDA AMS Certifications | Ensures equipment is designed for easy cleaning and inspection to prevent contamination. |

| European Declarations of Conformity | Confirms compliance with health and safety regulations, product labeling, and good manufacturing practices. |

Tip: Always ask for documentation of these certifications before making a purchase.

Technical Support

Strong technical support helps keep your production running smoothly. A good supplier offers installation guidance, operator training, and troubleshooting assistance. Quick response times and clear communication are important. TOPSGROUP provides ongoing support, helping customers solve problems and optimize their processes. Reliable technical support reduces downtime and improves productivity.

Customization

Every food manufacturing process has unique needs. Leading suppliers offer a range of customization options to match your requirements. These options can include special materials, discharge mechanisms, or control systems.

|

Customization Aspect |

Description |

| Custom Designs | Tailored designs to meet specific client requirements. |

| Material Selection | Options for materials suitable for various applications, including food grade. |

| Corrosive Material Option | SS 316 for applications involving corrosive materials. |

| Discharge Mechanism | Options for pneumatic or manual discharge. |

| Heating Design | Availability of heating or jacketed designs. |

| Control System | PLC control panel for enhanced operation. |

Customization ensures the blender fits your process and improves efficiency.

Warranty

A strong warranty protects your investment. Suppliers may offer different warranty periods depending on the product. For example, some powder mixers come with a five-year warranty, while others offer two years for parts and labor or for defects in materials and workmanship.

|

Product |

Warranty Period |

| Powder Mixer Pharmaceutical FZH 500 | 5 years |

| Blendtec Total Blender | 2 years (parts and labor) |

| Beast® Blender | 2 years (defects in material and workmanship) |

Note: Review warranty terms carefully to understand what is covered and for how long.

Evaluating suppliers on these four points helps ensure you choose a partner who supports your success in food manufacturing.

Final Selection

Selection Checklist

A careful selection process helps ensure the right equipment for your food manufacturing needs. Use this checklist to guide your decision:

• Powder flow characteristics: Check the bulk density, particle size, and cohesiveness of your powders. These factors affect how well the blender will mix your ingredients.

• Blender size: Choose a blender that matches your batch volume. Most blenders work best when filled to 35% to 65% of their total capacity.

• Capacity calculation: Calculate the correct blender size by knowing the density of your powder. This helps achieve even mixing and prevents overloading.

• Hygiene and cleaning: Confirm that the design allows for easy cleaning and meets food safety standards.

• Material compatibility: Make sure the blender is made from food-grade materials, such as stainless steel.

• Mixing method: Select a mixing method that fits your product type, whether you need gentle or intense blending.

• Automation and controls: Decide if you need automation features for better control and efficiency.

• Supplier support: Choose a supplier who offers technical support, customization, and a strong warranty.

Tip: Review each item on this checklist before making your final choice.

Mistakes to Avoid

Many manufacturers make common mistakes when choosing a Powder Blender. Avoid these pitfalls for better results:

1.Overlooking material properties. Not considering powder characteristics can lead to poor mixing.

2.Ignoring production size and capacity. A mismatch can cause inefficiency and wasted resources.

3.Selecting the wrong mixing method. This can result in uneven blends and product quality issues.

4.Neglecting build quality, cleanliness, and safety. These oversights can lead to contamination or safety hazards.

5.Focusing only on initial cost. Not considering long-term maintenance and customization needs can increase expenses over time.

Careful planning and attention to these details help you make a confident, informed decision.

Selecting the right powder blender for food manufacturing requires careful evaluation. Manufacturers should match blender features to their specific needs. The table below highlights important factors to consider:

|

Key Factor |

Description |

| Type of Blending Process | Choose batch or continuous based on recipe changes and production needs. |

| Powder Characteristics | Check flowability and particle size for effective mixing. |

| Batch Size | Consider how batch size affects loading and emptying times. |

| Mixing Time | Look at the total time from filling to emptying the mixer. |

| Changeover Time | Plan for cleaning and recipe changes, especially in batch processing. |

| Motor Power | Ensure the motor meets workload demands and performance metrics. |

Review your requirements and consult with trusted suppliers like TOPSGROUP to ensure reliable and efficient production.

FAQ

What is the main purpose of a powder blender in food manufacturing?

A powder blender mixes dry ingredients to create a uniform blend. This process ensures that every batch has the same taste, texture, and quality. Consistent mixing helps prevent product defects.

How do I choose the right size powder blender?

Check your batch size and production volume. Select a blender that can handle your largest batch without overfilling. Most blenders work best when filled to 35% to 65% of their total capacity.

Why is stainless steel important for powder blenders?

Stainless steel resists rust and contamination. It meets food safety standards and is easy to clean. This material helps keep food products safe and high in quality.

Can powder blenders handle both powders and small granules?

Yes. Many powder blenders, like those from TOPSGROUP, can mix powders and small granules. Some models also allow for the addition of liquids during mixing for more complex recipes.

What safety features should I look for in a powder blender?

Look for dust-tight seals, grounded components, and safety interlocks. These features protect workers and prevent contamination. Always check that the blender meets industry safety standards.

Post time: Feb-09-2026