Shanghai Tops-group is a manufacturer of auger filling machines with large production capacity and advanced technology. We have a patent on the presence of a servo auger filler. Furthermore, we can customize the auger filler to your specifications. We also sell auger filling machine parts. We can also use a particular brand if you have an object layout.

There are different types of auger filling machines, and those are:

- Semi-automatic Auger Filler

- Semi-automatic Auger Filler with Pouch Clamp

- Line-type Automatic Auger Filler for Bottles

- Rotary Automatic Auger Filler

- Double head auger filler

The Application and Industry to Which It Is Appropriate

Semi-automatic Auger Filler is suitable for fluidic or low-fluidity materials like:

Food Industry: coffee powder, wheat flour, condiment, solid drink

Pharmaceutical Industry: veterinary drugs, dextrose, pharmaceuticals, powder additive

Agricultural Industry: agriculture pesticide, and more

Construction industry: talcum powder, and more

Chemical Industry: dyestuff, and more

Semi-automatic Auger Filler with Pouch Clamp is suitable for fluidic or low-fluidity powder and small granular materials like:

Food Industry: instant noodles, flour, proteins, flavors, sweetener, condiment, solid coffee powder, formula milk powder

Pharmaceutical Industry: medicines, beverages, veterinary medications, dextrose

Construction industry: talcum powder, and more

Agricultural Industry: agriculture pesticide, and more

Chemical Industry: dyestuff, and more

Line-type Automatic Auger Filler for Bottles is mostly fluidic or low-fluidity materials, such as:

Food Industry: coffee powder, wheat flour, condiments, solid drinks

Pharmaceutical Industry: veterinary medications, dextrose, powder additives

Construction industry: talcum powder, and more

Agricultural Industry: agriculture pesticide, and more

Chemical Industry: dyestuff, and more

Rotary Automatic Auger Filler is used in fluidic or low-fluidity materials, like:

Food Industry: Coffee powder, wheat flour, condiment, solid drink,

Pharmaceutical Industry: veterinary drugs, dextrose, pharmaceuticals, powder additive

Construction industry: talcum powder and more

Agricultural Industry: agriculture pesticide and more

Chemical Industry: dyestuff and so on.

Double head auger filler is commonly used in the manufacturing of milk powder.

Principles of Each Type of Auger Filling Machines

Semi-automatic Auger Filler

The semi-automatic auger filling machine is ideal for low-speed filling. It can handle both bottles and pouches because the operator must manually arrange bottles on a plate under the filler and move them away after filling. The hopper can be completely made of stainless steel. Besides, the sensor could be a tuning fork sensor or a photoelectric sensor. We have small auger filling, standard models, and high-level powder auger filling.

Semi-automatic Auger Filler with Pouch Clamp

The pouch filling machine has a pouch clamp and is a semi-automatic auger filler. The pouch clamp will automatically hold the bag after stamping the pedal plate. It will automatically release the bag once it has been filled. Because the TP-PF-B12 is a big model, it includes a plate that raises and lowers the bag during filling to reduce dust and weight error. It has a load cell that can detect actual weight; gravity will cause an error if the powder is poured from the end of the filler to the bottom of the bag. The plate raises the bag, allowing the filling tube to enter. The plate gently falls during the filling process.

Line-type Automatic Auger Filler for Bottles

A line-type automatic auger filling is commonly used in powder bottle filling. It can be linked to a powder feeder, powder mixer, capping, and labeling machine to create an automatic packing line. The bottle stopper holds back bottles so that the bottle holder can use the conveyor to raise the bottle under the filler. The conveyor automatically moves each bottle forward after it has been filled. It can handle all bottle sizes on a single machine and is ideal for users with a variety of packaging dimensions. A halted stainless-steel hopper and a full stainless-steel hopper are available as options. There are two kinds of sensors on the market. It can also be customized to include an online weighing capability for extreme precision.

Rotary Automatic Auger Filler

A high-speed rotary auger filler can be used to fill the bottles. Because the bottle wheel can only accept one diameter, this type of auger filler is best suited for clients with one or two-diameter bottles. The speed and accuracy are faster and more accurate than with a line-type auger filler. The rotary type also has online weighing and rejection functions. In real-time, the filler will load powder based on the filling weight, and the rejection function will identify and remove disqualified weight. The machine cover is a personal choice.

Double head auger filler

A double-head auger filler is used to achieve high-speed filling. The fastest speed is 100 beats per minute. The check weighing and reject system prevents costly product waste due to the high accuracy of weight control. It is frequently used in the production of milk powder.

Powder packing system

When the auger filler and the packing machine are combined, a powder packing machine is shaped. It can work in tandem with a roll film sachet filling and sealing machine, a micro doypack packing machine, a rotary pouch packing machine, or a premade pouch packing machine.

Auger Filling Machine with Online Weighing System

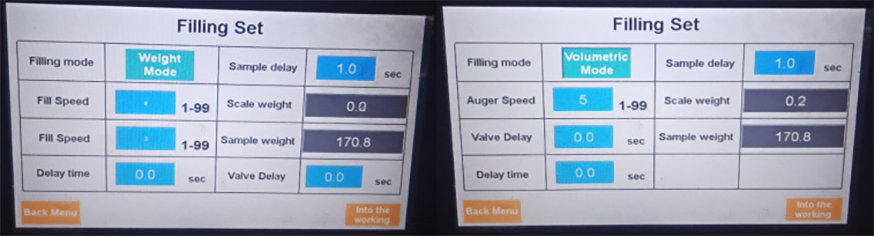

It is easy to switch between weight and volume modes.

Volume mode

The powder volume reduced by turning the screw one round is solved. The control system will determine how many turns the screw must make to achieve the desired fill weight.

Weight mode

Under the filling plate is a load cell that measures the filling weight in actual time. The first filling is quick and mass-filled to achieve 80% of the target filling weight.

The second filling is slow and precise, supplementing the remaining 20% based on the timely filling weight.

Weight mode is more accurate but slower.

Post time: Mar-21-2022