Filling and dosing are done with an dry powder filling machine. Coffee powder, wheat flour, condiments, solid drinks, veterinary medications, dextrose, powder additives, talcum powder, insecticides, dyestuff, and other materials are suitable for each type of dry powder filling machine. Dry powder filling machines are used in a variety of industries, including pharmaceuticals, agriculture, chemical, food, and construction.

We perform admirably in the areas of central components, processing precision, and assembly. Processing precision and assembly are undetectable to the human eye and cannot be immediately compared, but it will become clearer during use.

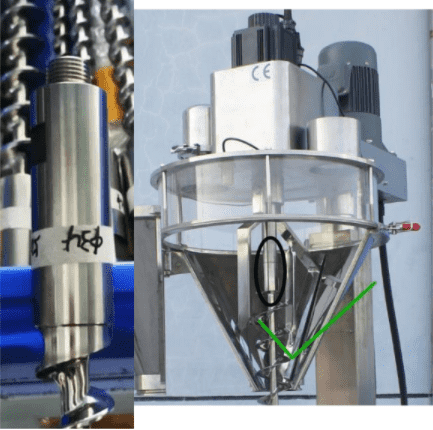

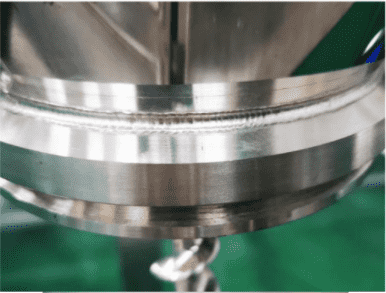

High concentricity:

- ● The accuracy will not be in a high level if there is no high concentricity on auger and shaft.

- ● We used a global famous brand shaft for the auger and servo motor.

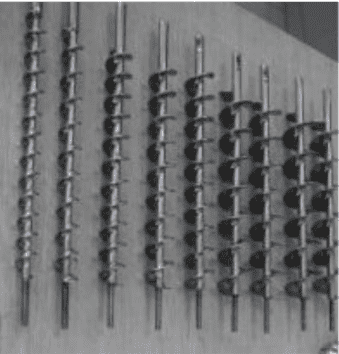

Precision machining:

- ● We use a milling machine to grind small augers, ensuring that it has uniform distances and a perfect shape.

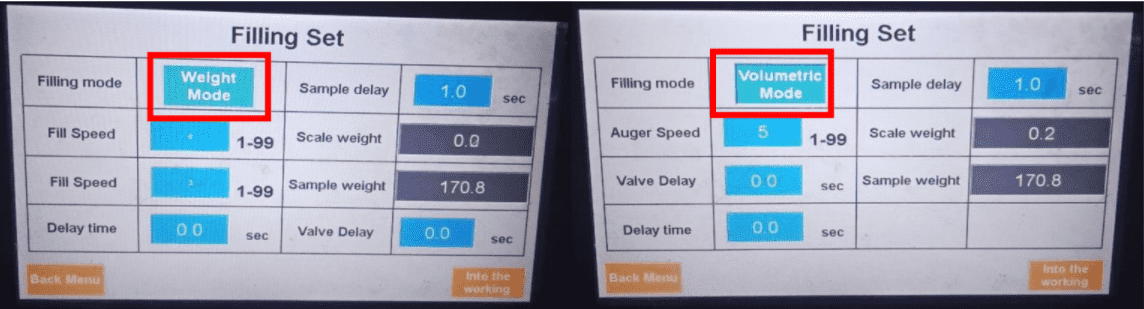

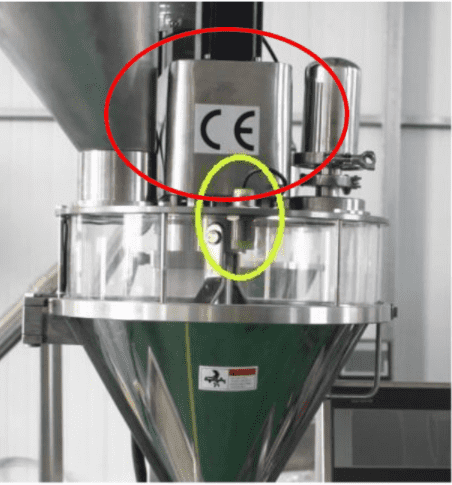

Two filling modes:

- ● The weight and volume modes can be switched.

Weight Mode: Under the filling plate is a load cell that measures the filling weight in real time. To achieve 80% of the required filling weight, the first filling is quick and mass filling. The second filling is slow and precise, supplementing the remaining 20% according to the weight of the first filling. The accuracy of the weight mode is higher, but the speed is slower.

Volume mode: The powder volume reduced by turning the screw one round is fixed. The controller will figure out how many turns the screw needs to make in order to reach the desired filling weight.

Main Features:

-To ensure perfect filling accuracy, a lathing auger screw is used.

-PLC control and a touch screen display are also used.

- To ensure accurate results, a servo motor powers the screw.

-The split hopper could well be quickly cleaned without the need for any devices.

- Full stainless steel 304 material that could be configured to semi-auto filling through a pedal switch.

- Weight feedback and proportion track to components, which solves the challenges of filling weight variations owing to density variations in components.

-Save 20 formula settings for subsequent use in the machine.

-Varied materials ranging from fine powder to granule and different weights can be packed by switching the auger pieces.

-The user interface is available in a variety of languages.

Different Types of Dry Powder Filling Machine

1.Desktop table

Filling works can be done with a desktop table type of dry powder filling machine. It is operated manually by placing the bottle or pouch on the plate beneath the filler and then moving the bottle or pouch away after filling. A shaking fork sensor or a photoelectric sensor can be used to detect powder level. Dry powder filling machine is the smallest model for laboratory.

Specification

| Model | TP-PF-A10 | TP-PF-A11 TP-PF A11S | TP-PF-A14 TP-PF-A14S | ||||||

| Controlsystem | PLC &Touch Screen | PLC & Touch Screen | PLC & Touch Screen | ||||||

| Hopper | 11L | 25L | 50L | ||||||

| PackingWeight | 1-50g | 1-500g | 10-5000g | ||||||

| Weightdosing | By auger | By auger By load cell | By auger By load cell | ||||||

| WeightFeedback | By off-line scale ( in picture) | By off-line Onlinescale ( in weightpicture) feedback | By off-line Onlinescale ( in weightpicture) feedback | ||||||

| PackingAccuracy | ≤ 100g, ≤±2% | ≤ 100g, ≤±2%; 100 –500g, ≤±1% | ≤ 100g, ≤±2%; 100 – 500g, ≤±1%;>500g, ≤±0.5% | ||||||

| Filling Speed | 20 – 120 times per min | 20 – 120 times per min | 20 – 120 times per min | ||||||

| PowerSupply | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | ||||||

| Total Power | 0.84 KW | 0.93 KW | 1.4 KW | ||||||

| Total Weight | 90kg | 160kg | 260kg | ||||||

| OverallDimensions | 590×560×1070mm | 800×790×1900mm | 1140×970×2200mm | ||||||

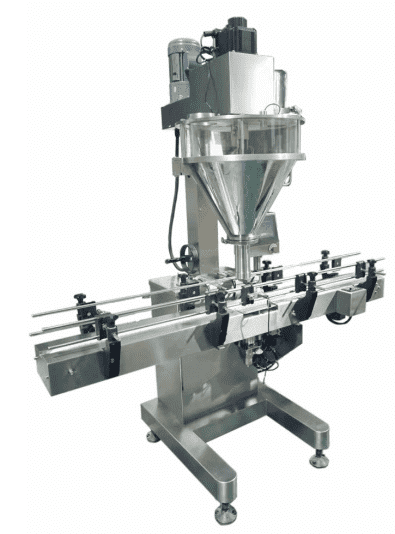

2.Semi-auto type

Semi-automatic type of dry powder filling machine work well for filling. Manually operated by placing the bottle or pouch on the plate beneath the filler and then moving the bottle or pouch away once it has been filled. A tuning fork sensor or a photoelectric sensor can be used as the sensor. You can have smaller dry powder filling machine and standard models, and high-level models of dry powder filling machine for powder.

Specification

| Model | TP-FF-A11 TP-PF A11N | TP-PF-A11S TP-PF A11NS | TP-FF-A14 TP-PF-A14N |

| Control

system |

PLC & Touch Screen | PLC & Touch Screen | PLC & Touch Screen |

| Hopper |

25L |

25L |

50L |

| Packing

Weight |

1-500g |

1-500g |

1-5000g |

| Weight

dosing |

By auger By load cell | By auger By load cell | By auger By load cell |

| Weight

Feedback |

By off-line Online

scale ( in weight picture) feedback |

By off-line Online

scale ( in weight picture) feedback |

By off-line Online

scale ( in weight picture) feedback |

| Packing

Accuracy |

≤ 100g, ≤±2%; 100 –

500g, ≤±1% |

≤ 100g, ≤±2%; 100 –

500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±0.5% |

| Filling Speed | 20 – 120 times per min | 20 – 120 times per min | 20 – 120 times per min |

| Power

Supply |

3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Total Power |

0.93 KW |

0.93 KW |

1.4 KW |

| Total Weight |

160kg |

160kg |

260kg |

| Overall

Dimensions |

800×790×1900mm | 800×790×1900mm | 1140×970×2200mm |

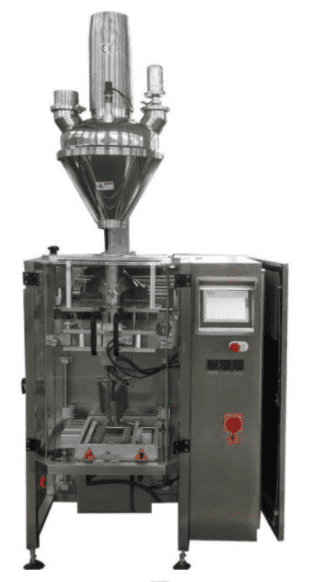

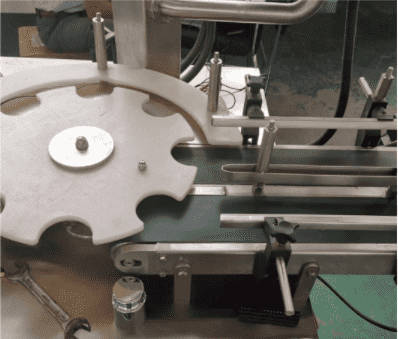

3.Automatic liner type

Dry powder filling machine with automatic lines perform well for dosing and filling. The bottle stopper holds back bottles so that the bottle holder can lift the bottle under the filler, and the conveyor moves the bottle in automatically. After the bottles have been filled, the conveyor moves them forward automatically. It is perfect for users who have different packing dimensions because it can handle different sizes of bottle on one machine. The fork sensor and the photoelectric sensor are the two types of sensors accessible. It can be combined with a powder feeder, a powder mixer, a capping machine, and a labeling machine to create an automatic packing line.

Specification

|

Model |

TP-PF-A21 |

TP-PF-A22 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

25L |

50L |

|

Packing Weight |

1 - 500g |

10 - 5000g |

|

Weight dosing |

By auger |

By auger |

|

Weight Feedback |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

|

Packing Accuracy |

40 – 120 times per min |

40 – 120 times per min |

|

Filling Speed |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

1.2 KW |

1.6 KW |

|

Total Weight |

160kg |

300kg |

|

Overall Dimensions |

1500×760×1850mm |

2000×970×2300mm |

4.Automatic rotary type

A high-speed automatic rotary type is used to put powder into bottles. Because the bottle wheel can only accommodate one diameter, this type of dry powder filling machine is best for customers who only have one or two diameter bottles. In general, the speed and precision of the automatic liner type are greater. Additionally, the automatic rotary type has online weighing and rejection capabilities. The filler will fill powder in real time based on the filling weight, with the rejection mechanism recognizing and discarding unqualified weight. The machine cover is a personal preference.

Specification

|

Model |

TP-PF-A32 |

TP-PF-A31 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

35L |

50L |

|

Packing Weight |

1-500g |

10 - 5000g |

|

Weight dosing |

By auger |

By auger |

|

Container size |

Φ20~100mm ,H15~150mm |

Φ30~160mm ,H50~260mm |

|

Packing Accuracy |

≤ 100g, ≤±2% 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% ≥500g,≤±0.5% |

|

Filling Speed |

20 – 50 times per min |

20 – 40 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

1.8 KW |

2.3 KW |

|

Total Weight |

250kg |

350kg |

|

Overall Dimensions |

1400*830*2080mm |

1840×1070×2420mm |

5.Big bag type

This big bag is designed to hold a large amount of material weighing more than 5kg but less than 50kg. This machine can perform measurements, two-filling, up-down work, and other operations. The following is based on the weight sensor's feedback. It's suitable for filling fine powders that require precise packing, such as additives, carbon powder, fire extinguisher dry powder, and other fine powders, just like other types of dry powder filling machines.

Specification

|

Model |

TP-PF-B11 |

TP-PF-B12 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

Quick disconnecting hopper 70L |

Quick disconnecting hopper 100L |

|

Packing Weight |

100g-10kg |

1-50kg |

|

Dosing mode |

With online weighing; Fast and slow filling |

With online weighing; Fast and slow filling |

|

Packing Accuracy |

100-1000g, ≤±2g; ≥1000g,±0.2% |

1 – 20kg, ≤±0.1-0.2%, >20kg, ≤±0.05-0.1% |

|

Filling speed |

5 – 30 times per min |

2– 25 times per min |

|

Power supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total power |

2.7 KW |

3.2 KW |

|

Total weight |

350kg |

500kg |

|

Overall Dimensions |

1030×850×2400mm |

1130×950×2800mm |

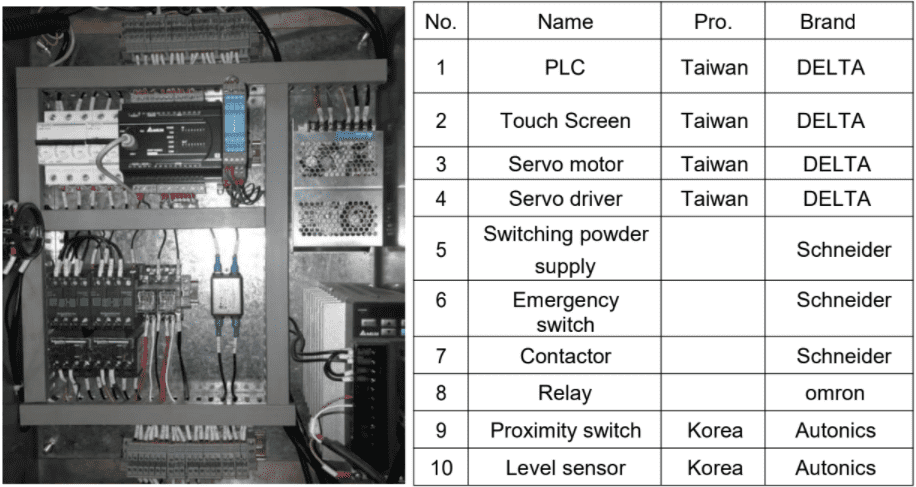

Configuration Lists

|

No. |

Name |

Specification |

Pro. |

Brand |

|

1 |

Stainless steel |

SUS304 |

China |

|

|

2 |

Touch Screen |

Germany |

Siemens |

|

|

3 |

Servo motor |

Taiwan |

Delta |

|

|

4 |

Servo driver |

ESDA40C-TSB152B27T |

Taiwan |

TECO |

|

5 |

Agitator motor |

0.4kw,1:30 |

Taiwan |

CPG |

|

6 |

Switch |

Shanghai |

||

|

7 |

Emergency switch |

Schneider |

||

|

8 |

Filter |

Schneider |

||

|

9 |

Contactor |

Wenzhou |

CHINT |

|

|

10 |

Hot relay |

Wenzhou |

CHINT |

|

|

11 |

Fuse seat |

RT14 |

Shanghai |

|

|

12 |

Fuse |

RT14 |

Shanghai |

|

|

13 |

Relay |

Omron |

||

|

14 |

Switching power supply |

Changzhou |

Chenglian |

|

|

15 |

Proximity switch |

BR100-DDT |

Korea |

Autonics |

|

16 |

Level sensor |

Korea |

Autonics |

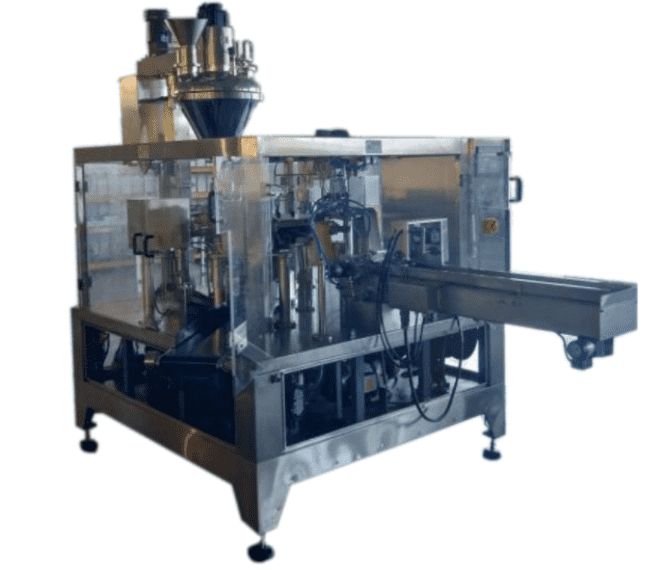

Powder packing system

A powder packing machine is made when the dry powder filling machine and the packing machine are combined. It can be utilized in connection with a roll film sachet filling and sealing machine, a micro doypack packing machine, a rotary pouch packing machine, or a prefabricated pouch packing machine.

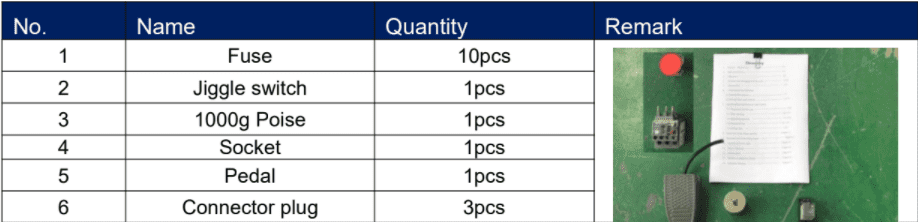

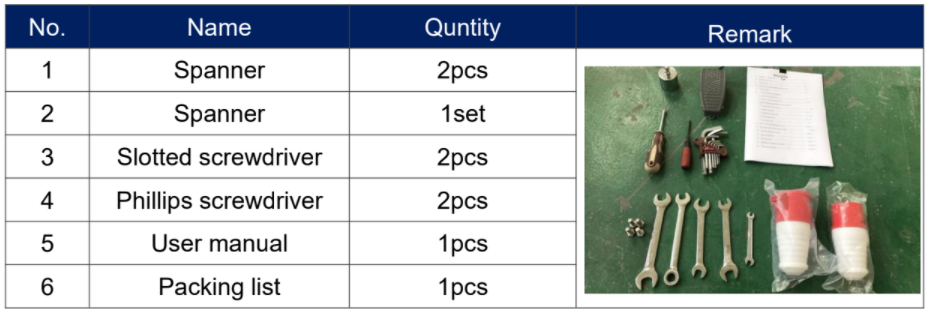

Configuration List of Dry Powder Filling Machine

Dry Powder Filling Machine Details

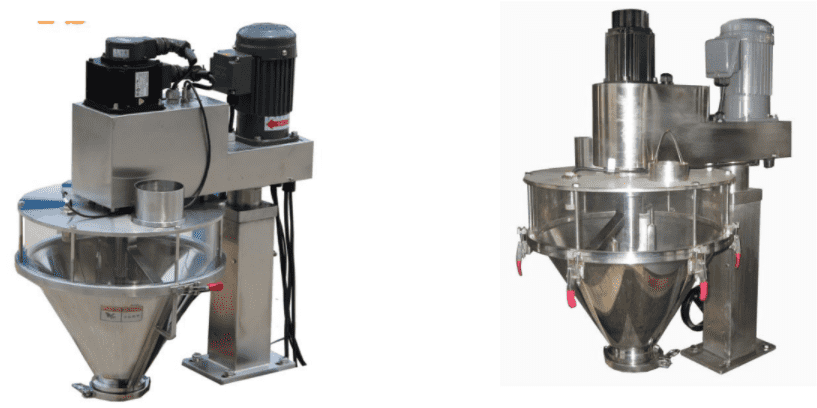

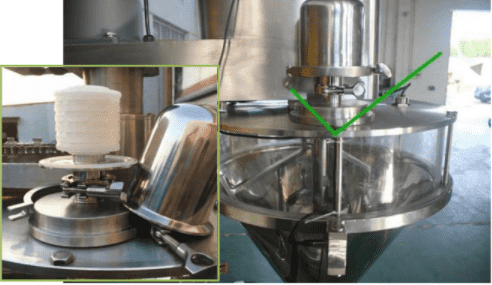

● Optional Hopper

Half open hopper

This level split hopper is easy to clean and open.

Hanging hopper

Combine hopper is fit for fine powder and there is no gap at lower part of hopper.

● Filling mode

Weight and volume modes are changeable.

Volume mode

The powder volume reduced by turning the screw one round is fixed. The controller will figure out how many turns the screw needs to make in order to reach the desired filling weight.

Auger powder filling machine fixing way

Screw type

There are no gaps inside where powder might hide, and it's easy to clean.

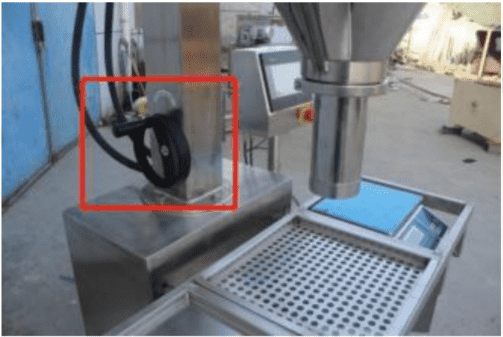

Auger powder filling machine hand wheel

It is suitable to fill bottles and bags of different heights. To raise and lower the filler by turning the hand wheel. And our holder is thicker and more durable.

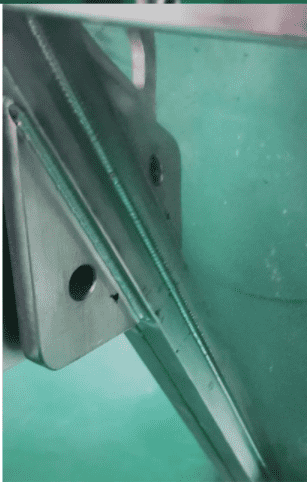

Auger powder filling machine processing

Full welded including the hopper edge and easy to clean.

Auger powder filling machine motor base

The entire machine, including the base and motor holder, is made of SS304, which is durable and high material.

Auger powder filling machine air outlet

This special design is for preventing dust to fall into the hopper. It is easy to clean and high level.

Auger powder filling machine two output belt

One belt collects weight qualified bottles, while the other belt collects weight unqualified bottles.

Auger powder filling machine different sizes metering auger and filling nozzles

Dry powder filling machine maintenance

● Add a little oil once in three or four months.

● Add a little Grease on stir motor chain once in three or four months.

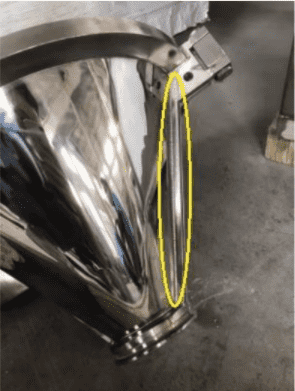

● The sealing strip on both sides of the material bin may become aging nearly one year later. Replace them if needed.

● The sealing strip on both sides of hopper may become aging nearly one year later. Replace them if needed.

● Clean the material bin in time.

● Clean hopper in time.

Dry powder filling machine sizes and related filling weight ranges

Cup Sizes and Filling Range

|

Order |

Cup |

Inner Diameter |

Outer Diameter |

Filling Range |

|

1 |

8# |

8 |

12 |

|

|

2 |

13# |

13 |

17 |

|

|

3 |

19# |

19 |

23 |

5-20g |

|

4 |

24# |

24 |

28 |

10-40g |

|

5 |

28# |

28 |

32 |

25-70g |

|

6 |

34# |

34 |

38 |

50-120g |

|

7 |

38# |

38 |

42 |

100-250g |

|

8 |

41# |

41 |

45 |

230-350g |

|

9 |

47# |

47 |

51 |

330-550g |

|

10 |

53# |

53 |

57 |

500-800g |

|

11 |

59# |

59 |

65 |

700-1100g |

|

12 |

64# |

64 |

70 |

1000-1500g |

|

13 |

70# |

70 |

76 |

1500-2500g |

|

14 |

77# |

77 |

83 |

2500-3500g |

|

15 |

83# |

83 |

89 |

3500-5000g |

You can contact us and we will help you to choose the right size of your desired dry powder filling machine.

Dry powder filling machine sample products

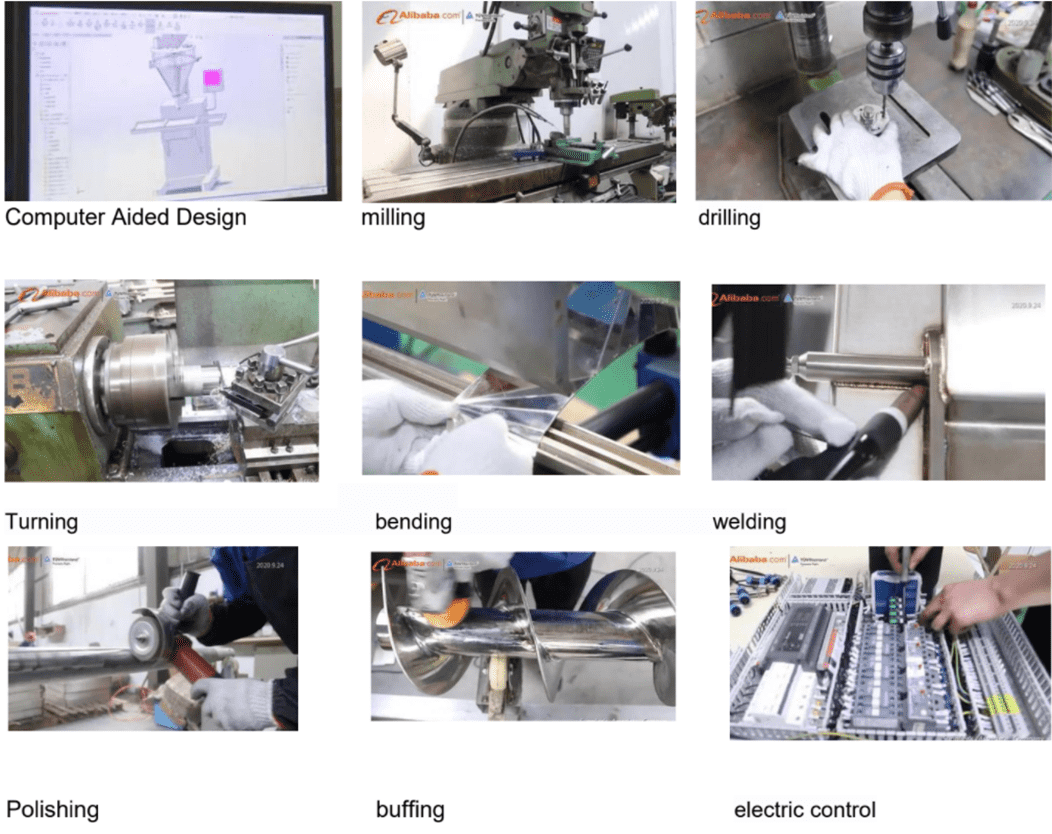

Dry powder filling machine processing

Factory Show

We are a professional packaging machine supplier that specialize in the fields of designing, manufacturing, supporting, and servicing a complete line of machinery for different types of liquid, powder, and granular products. We utilized in the production of agriculture industry, chemical industry, food industry, and pharmacy fields, and many more. We are commonly known for its advanced design concept, professional technique support and high quality machines.

Tops-Group looks forward to providing you with amazing service and exceptional products of machines based on its corporate values of TRUST, QUALITY, and INOVATION! All together let’s create valued relationship and build a successful future.