Description

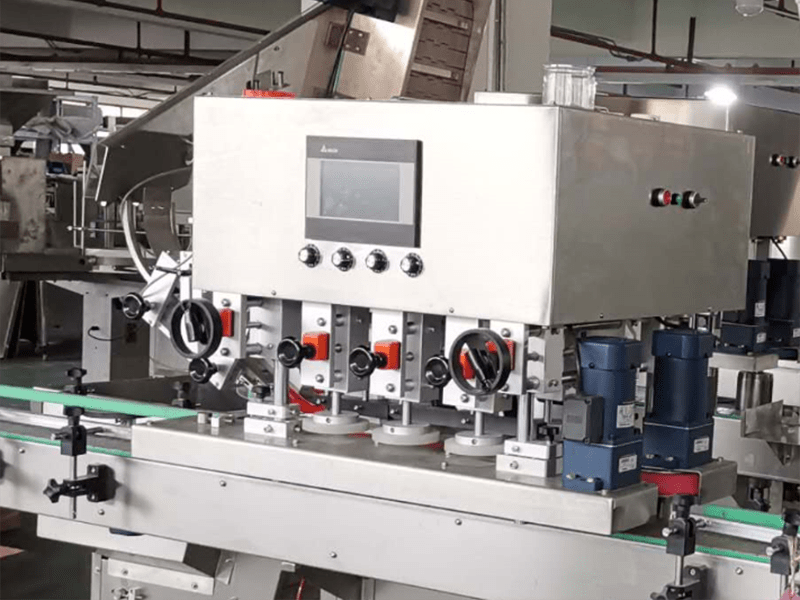

The TP-TGXG-200 Bottle Capping Machine is an automated system specially designed to press and screw lids onto bottles within an automatic packing line. Unlike traditional intermittent capping machines, this model features a continuous capping design, offering greater efficiency, tighter sealing, and reduced lid damage. As a result, it is widely utilized across the food, pharmaceutical, and chemical industries.

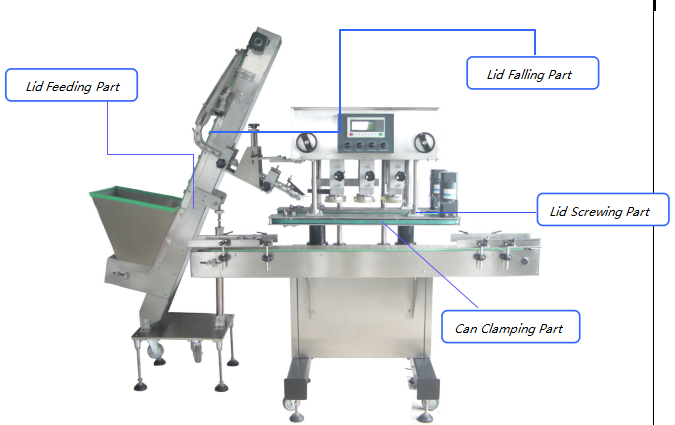

It consists of two parts: capping part and lid feeding part. It works as following: Bottles coming(can joint with auto packing line)→Convey→Separate bottles in same distance→Lift lids→Put on lids→Screw and press lids→Collect bottles.

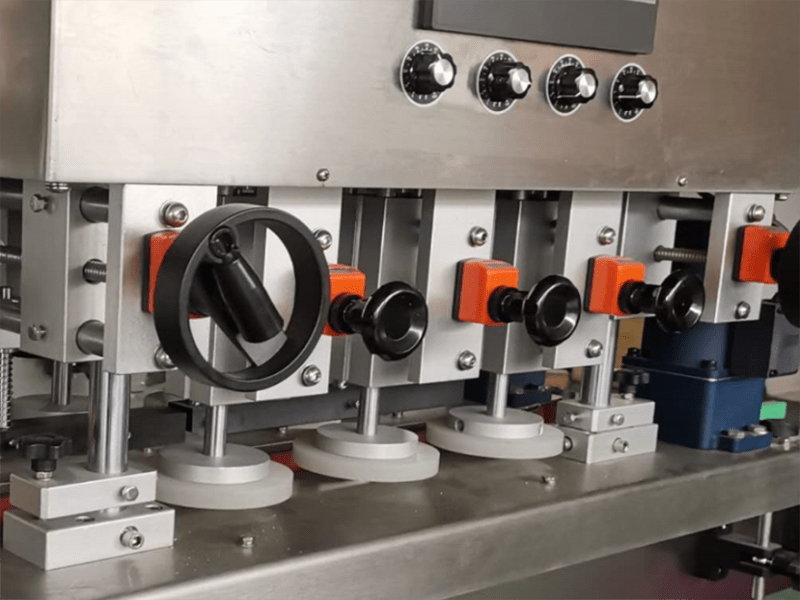

Details

Intelligent

Automatic error lids remover and bottle sensor, assure good capping effect

Convenient

Adjustable according to height, diameter, speed, suit more bottles and less frequent to change parts.

Efficient

Linear conveyor, automatic cap feeding, max speed 80 bpm

Easy operate

PLC&touch screen control, easy to operate

Characteristics

■ PLC&touch screen control, easy to operate

■ Easy to operate , Speed of conveying belt is adjustable to synchronous with whole system

■ Stepped lifting device to feed in lids automatically

■ Lid falling part can remove error lids away(by air blowing and weight measuring)

■ All the contact parts with bottle and lids are made of material safety for food

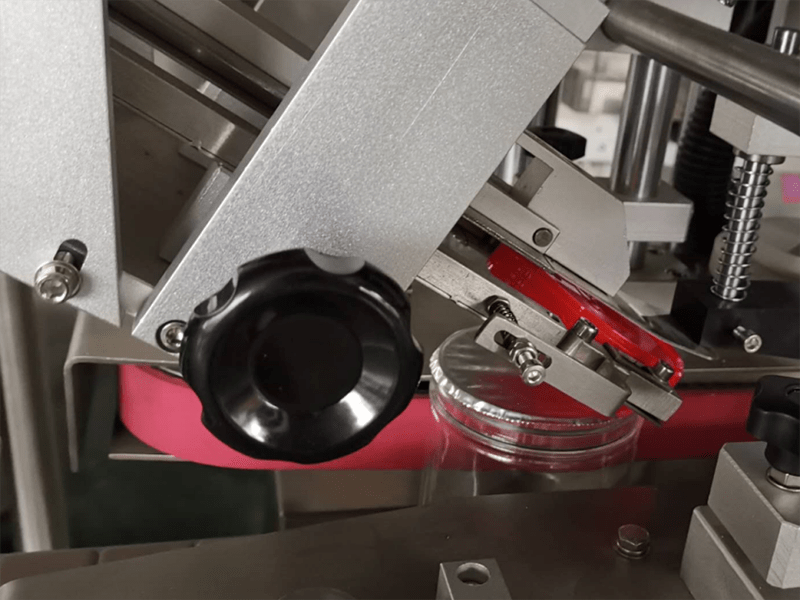

■ The belt to press the lids is inclined, so it can adjust the lid into the correct place and then pressing

■ Machine body is made of SUS 304, meet GMP standard

■ Optronic sensor to remove the bottles which are error capped (Option)

■ Digital display screen to show the size of different bottle, which will be convenient for changing bottle(Option).

Parameters

|

TP-TGXG-200 Bottle Capping Machine |

|||

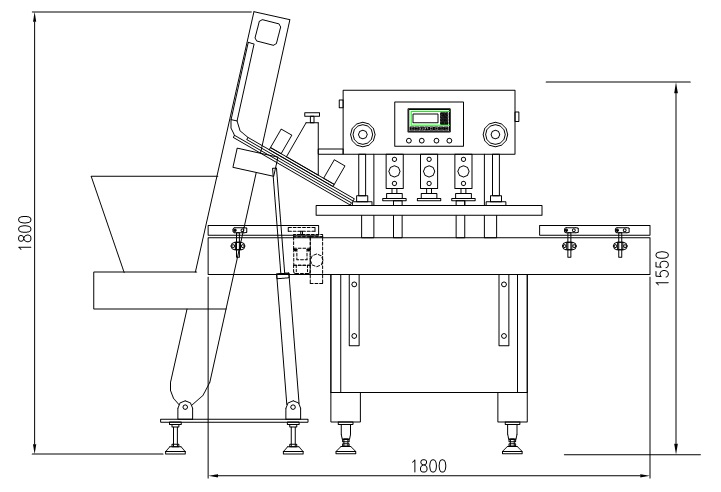

| Capacity | 50-120 bottles/min | Dimension | 2100*900*1800mm |

| Bottles diameter | Φ22-120mm ( customized according to requirement ) | Bottles height | 60-280mm (customized according to requirement ) |

| Lid size | Φ15-120mm | Net Weight | 350kg |

| Qualified rate | ≥99% | Power | 1300W |

| Matrial | Stainless steel 304 | Voltage | 220V/50-60Hz(or customized) |

Standard Configuration

|

No. |

Name |

Origin |

Brand |

|

1 |

Invertor |

Taiwan |

Delta |

|

2 |

Touch Screen |

China |

TouchWin |

|

3 |

Optronic Sensor |

Korea |

Autonics |

|

4 |

CPU |

US |

ATMEL |

|

5 |

Interface Chip |

US |

MEX |

|

6 |

Pressing Belt |

Shanghai |

|

|

7 |

Series Motor |

Taiwan |

TALIKE/GPG |

|

8 |

SS 304 Frame |

Shanghai |

BaoSteel |

Structure & Drawing

DetailsShippment & Packaging

ACCESSORIES in Box :

■ Instruction manual

■ Electrical diagram and connecting diagram

■ Safety operation guide

■ A set of wearing parts

■ Maintenance tools

■ Configuration list (origin, model, specs, price)

Factory Show

Our Team

Customers visiting

Customer site service

Our two engineers went to client’s factory in Spain for after-sales service in 2017.

Engineers went to client’s factory in Finland for after-sales service in 2018.

Service & Qualifications

■ TWO YEAR warranty, ENGINE THREE YEARS warranty, life-long service

(Warranty service will be honored if the damage is not caused by human or improper operation)

■ Provide accessory parts in favorable price

■ Update configuration and program regularly

■ Respond to any question in 24 hours

FAQ

1.Are you a capping bottle machine manufacturer?

Shanghai Tops Group Co., Ltd is one of the leading manufacturers of capping bottle machine in China, who has been in packing machine industry for over ten years.

2.Does your capping bottle machine have CE certificate?

Not only the capping bottle machine but also all our machines have CE certificate.

3.How long is the capping bottle machine delivery time?

It takes 7-10 days to produce a standard model. For customized machine, your machine can be done in 30-45 days.

4.What’s your company service and warranty?

■TWO YEAR warranty, ENGINE THREE YEARS warranty, life-long service (Warranty service will be honored if the damage is not caused by human or improper operation)

■Provide accessory parts in favorable price

■Update configuration and program regularly

■Respond to any question in 24 hours Site service or online video service

For the payment term, you can choose from following terms: L/C, D/A, D/P, T/T, Western Union, Money Gram, Paypal

For the shipping, we accept all term in contract like EXW, FOB, CIF, DDU etc.

5.Do you have the ability of design and propose solution?

Of course, we have professional design team and experienced engineer. For example, we designed a bread formula production line for Singapore BreadTalk.

6.How can I know your machine is designed for my product?

If you don't mind, you can send us samples and we will test on machines.During that time, we will take videos and clearer pictures for you. We can also show you on-line by video chatting.

7. How can I trust you for the first-time business?

Please note our business license and certificates above. If you don't trust us, we suggest using Alibaba Trade Assurance Service for all transactions to protect your money and assure our service for you.

8. How about the after service and guarantee period?

We offer 12 months warranty since the arrival of the machine. Technical support is available 24/7. CapsulCN highly recommends that you keep all of your original packaging. This is precautionary to ensure you have what you need if the machine has to be sent in for repair. We have professional team with experienced technician to serve abroad and do the best after service to assure the machine whole life usage.

9.How is the quality inspection before machine delivery ?

Before you make the order, our sales will communicate all details with you until you get a satisfying solution from our technician. We can use your product or similar one in the China market to test our machine, then feed you back the video to show the effect. After making the order, you can appoint an inspection body to check your ribbon mixer machine in our factory.