One. General description

TP-TGXG-200 Bottle Capping Machine is an automatic capping machine to press and

screw lids on bottles. It’s special designed for automatic packing line. Different to

traditional intermittent type capping machine, this machine is a continuous capping type. Compared to intermittent capping, this machine is more efficient, pressing more tightly, and do less harm to the lids. Now it’s widely applied in food, pharmaceutical, chemical industries.

Two. Application

It is applied for base threaded cover, Safety lock thread cover, Butterfly screw cap

Pump head threaded cover, and glass bottle.

Three. Core working principle

The cap management system arranges the cap and hangs it obliquely at 30°. When the bottle is separated by the bottle separation mechanism, it passes through the cap area, and the cap is brought down and covered on the bottle mouth. The bottle moves forward on the conveyor belt, and the top There is a capping belt to press the cap tightly, while the cap flows through 3 pairs of capping wheels, the capping wheels exert pressure on both sides of the cap, the cap is screwed tightly, and the capping action of a bottle is completed.

Four. The equipment parameters of this equipment introduction

| Model | GX-200T high speed capping machine |

| Production capacity (bottles/min) | 30~120 (depending on container and lid size) |

| Applicable bottle diameter (mm) | Φ40~90 (can be customized according to customer needs) |

|

Applicable cap diameter (mm) |

Φ30~60 (bottle drop track needs to be customized according to bottle cap specifications) |

| Dimensions (mm) | 2100×1000×1500 |

| Drop cover device | Lift drop cover device |

| Dimensions (mm) | 1080×600×1860 |

| Weight (kg) | 450 |

| Total motor power (w) | 1300 |

| Power | 220V / 50Hz |

Five. Features of this equipment

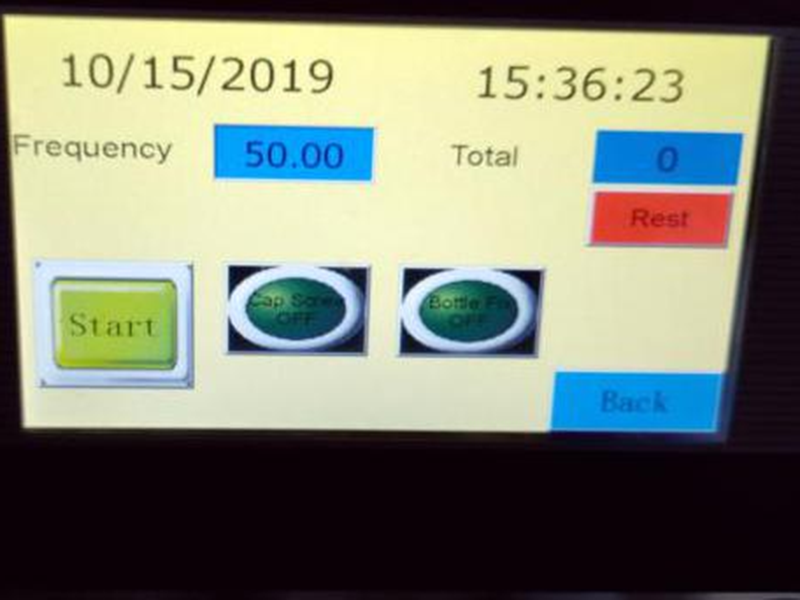

1. The whole machine adopts a touch screen with a Chinese interface, and the operation display is clear and easy to understand;

2. The mode of "one cover roller corresponds to one motor", there are 6 motors in total; it ensures that the equipment is stable and reliable, the torque is consistent, and the adjustment is convenient even under long-term fatigue working conditions;

3. The bottle-clamping belt can be adjusted individually to make it suitable for rubbing caps of bottles of different heights and shapes;

4. Equipped with a lifting motor, which can realize the automatic lifting and lowering of the lid rubbing host;

5.The parts in contact with the bottle and cap adopt non-toxic timing belt and non-toxic capping wheel;

6.Optional cap guide device, this device is also suitable for rubbing caps with pump heads;

7.Automatic capping and capping, reducing labor intensity of workers;

8. The shell of the fuselage is made of stainless steel 304 material, which meets the requirements of GMP;

9.Optional digital position display function can reduce the difficulty of operation and avoid the tight screw cap caused by insufficient adjustment. (different sizes of caps)

10.The size, bottle size, bottle height, and the height of the hoist are all digitally displayed, which is convenient for memorizing the adjustment when different products are replaced.

11.Can be equipped with automatic detection and rejection of bad cap products.

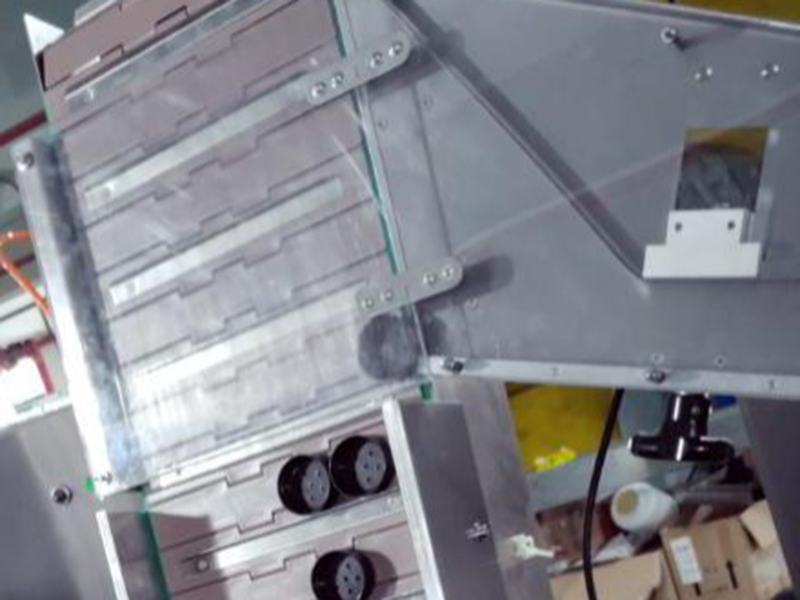

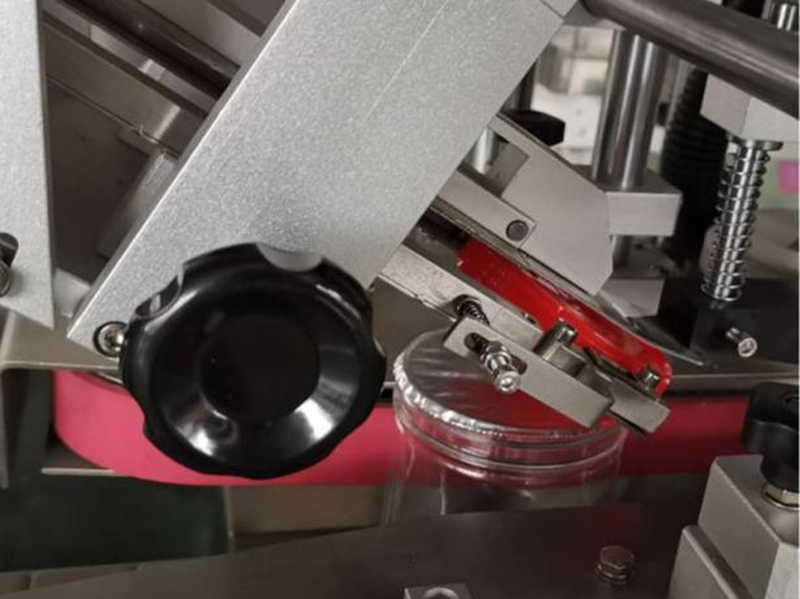

Six. Detailed Photos

1.Conveyor brings caps up and blowing device blow caps into track.

2.Sensor detecting makes cap feeder run and stop automatically.

3.Bottle separator can adjust the conveying speed of bottles.

4.Error caps sensor can find inverted caps easily. Automatic error lids remover and bottle sensor, assure good capping effect

5. The maximum speed of linear conveyor and automatic cap feeding is 100 bpm

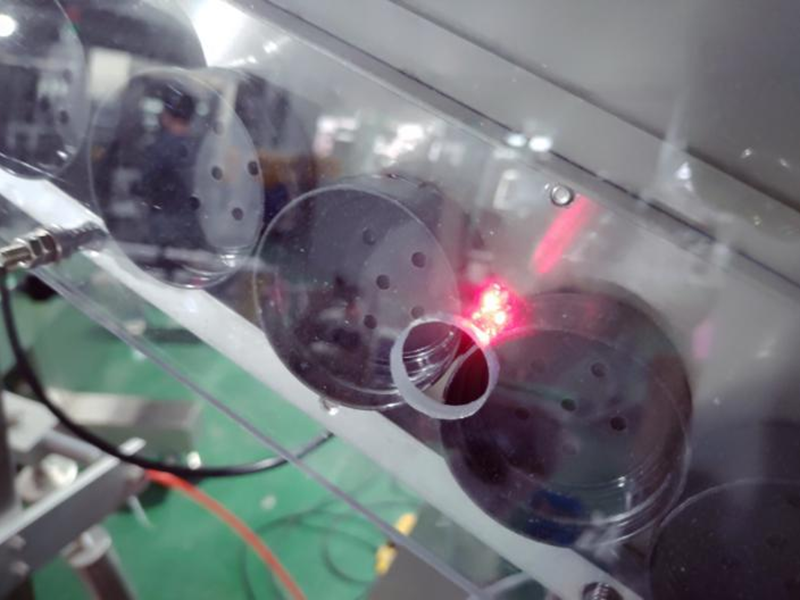

6. Three pairs of wheel twist cap off fast, the first pair can be set into reverse turn to make caps in its correct position quickly.

7. One button to adjust the height of whole capping device.

8. Switch to open, close and change speed of cap feeder, bottle conveyor, capping wheels and bottle separator.

9. PLC&touch screen control,easy to operate.

10. Emergency button to stop the machine

Seven. The equipment production connection line of this equipment introduction

Can be matched with two kinds of capping machines (lifting capping machine and vibrating plate)

Vibrating plate

Eight. Our team

Nine.Service & Qualifications

■TWO YEAR warranty, ENGINE THREE YEARS warranty, life-long service

(Warranty service will be honored if the damage is not caused by human or improper operation)

■Provide accessory parts in favorable price

■Update configuration and program regularly

Respond to any question in 24 hours

Shanghai Tops Group Co., Ltd is professional manufacturer for powder and granular packaging systems.

We specialize in the fields of designing, manufacturing, supporting and servicing a complete line of machinery for different kinds of powder and granular products; our main target of working is to offer the products which are related to the food industry, agriculture industry, chemical industry, and pharmacy field and more.

We value our customers and are dedicated to maintaining relationships to ensure continued satisfaction and create win-win relationship. Let’s work hard altogether and make much greater success in the near future!

FAQ

1. Are you a industrial capping machine manufacturer?

Shanghai Tops Group Co., Ltd is one of the leading capping machine manufacturers in China, who has been in packing machine industry for over ten years. We have sold our machines to more than 80 countries all over the world.

Our company has a number of invention patents of ribbon blender design as well other machines.

We have abilities of designing, manufacturing as well customizing a single machine or whole packing line.

2. Does your capping machine have CE certificate?

Not only the capping machine but also all our machines have CE certificate.

3. How long is the capping machine delivery time?

It takes 7-10 days to produce a standard model.

For customized machine, your machine can be done in 30-45 days.

Moreover, machine shipped by air is about 7-10 days.

Ribbon blender delivered by sea is about 10-60 days according to different distance.

4. What’s your company service and warranty?

Before you make the order, our sales will communicate all details with you until you get a satisfying solution from our technician. We can use your product or similar one in China market to test our machine, then feed you back the video to show the effect.

For the payment term, you can choose from following terms:

L/C, D/A, D/P, T/T, Western Union, Money Gram, Paypal

After making the order, you can appoint inspection body to check your powder ribbon blender in our factory.

For the shipping, we accept all term in contract like EXW, FOB, CIF, DDU and so on.

5. Do you have the ability of design and propose solution?

Of course, we have professional design team and experienced engineer. For example, we designed a bread formula production line for Singapore BreadTalk.

6. Does your powder mixing blender machine have CE certificate?

Yes, we have powder mixing equipment CE certificate. And not only coffee powder mixing machine, all our machines have CE certificate.

Moreover, we have some technical patents of powder ribbon blender designs, such as shaft sealing design, as well auger filler and other machines appearance design, dust-proof design.

7. What products can ribbon blender mixer handle?

Ribbon blender mixer can handle all kinds of powder or granule mixing and is widely applied in food, pharmaceuticals, chemical and so on.

Food industry: all kinds of food powder or granule mix like flour, oat flour, protein powder, milk powder, coffee powder, spice, chilli powder, pepper powder, coffee bean, rice, grains, salt, sugar, pet food, paprika, microcrystalline cellulose powder, xylitol etc.

Pharmaceuticals industry: all kinds of medical powder or granule mix like aspirin powder, ibuprofen powder, cephalosporin powder, amoxicillin powder, penicillin powder, clindamycin powder, azithromycin powder, domperidone powder, amantadine powder, acetaminophen powder etc.

Chemical industry: all kinds of skin care and cosmetics powder or industry powder mix, like pressed powder, face powder, pigment, eye shadow powder, cheek powder, glitter powder, highlighting powder, baby powder, talcum powder, iron powder, soda ash, calcium carbonate powder, plastic particle, polyethylene etc.

Click here to check if your product can works on ribbon blender mixer

8. How do industry ribbon blenders work?

Double layer ribbons which stand and turn in opposite angels to form a convection in different materials so that it can reach a high mixing efficiency.

Our special design ribbons can achieve no dead angle in mixing tank.

The effective mixing time is only 5-10 minutes, even less within 3 min.

9. How to select a double ribbon blender?

● Select between ribbon and paddle blender

To select a double ribbon blender, the first thing is to confirm if the ribbon blender is suitable.

Double ribbon blender is suitable for mixing different powder or granule with similar densities and which is not easy to break. It is not suitable for material which will melt or get sticky in higher temperature.

If your product is the mix consist of materials with very different densities, or it is easy to break, and which will melt or get sticky when temperature is higher, we recommend you to select the paddle blender.

Because the working principles are different. Ribbon blender moves materials in opposite directions to achieve good mixing efficiency. But paddle blender brings materials from tank bottom to top, so that it can keep materials complete and won’t make temperature go up during mixing. It won’t make material with larger density staying at tank bottom.

● Choose a suitable model

Once confirm to use the ribbon blender, it comes into making decision on volume model. Ribbon blenders from all suppliers have the effective mixing volume. Normally it is about 70%. However, some suppliers name their models as total mixing volume, while some like us name our ribbon blender models as effective mixing volume.

But most manufacturers arrange their output as weight not volume. You need to calculate the suitable volume according to your product density and batch weight.

For example, manufacturer TP produces 500kg flour each batch, whose density is 0.5kg/L. The output will be 1000L each batch. What TP needs is a 1000L capacity ribbon blender. And TDPM 1000 model is suitable.

Please pay attention to the model of other suppliers. Make sure 1000L is their capacity not total volume.

● Ribbon blender quality

The last but the most important thing is to choose a ribbon blender with high quality. Some details as following are for reference where problems are most likely to occur on a ribbon blender.

Shaft sealing: test with water can show the shaft sealing effect. Powder leakage from shaft sealing always troubles users.

Discharge sealing: test with water also shows the discharge sealing effect. Many users have met leakage from discharge.

Full-welding: Full welding is one of the most important part for food and pharmaceutical machines. Powder is easy to hide in gap, which may pollute fresh powder if residual powder goes bad. But full-welding and polish can make no gap between hardware connection, which can show machine quality and usage experience.

Easy-cleaning design: A easy-cleaning ribbon blender will save much time and energy for you which is equal to cost.

10. What’s the ribbon blender price?

The ribbon blender price is based on capacity, option, customization. Please contact us to get your suitable ribbon blender solution and offer.

11. Where to find a ribbon blender for sale near me?

We have agents in several countries, where you can check and try our ribbon blender, who can help you one shipping and customs clearance as well after-service. Discount activities are held from time to time of one year. Contact us to get the latest price of ribbon blender please.