Definition

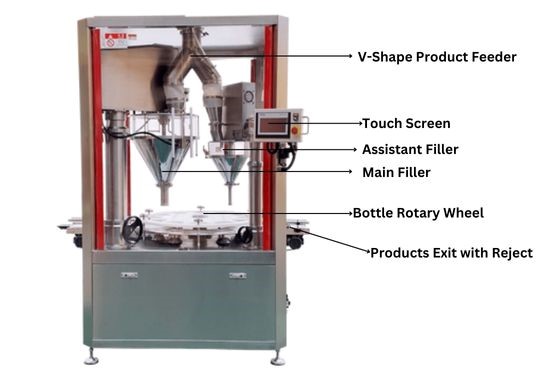

The dual-head powder filler meets the latest industry requirements and is GMP certified. Based on European packaging technology, this machine offers a robust and reliable layout. With an increase from eight to twelve stations, the turntable's single rotation angle has been dramatically reduced, leading to improved speed and stability. The machine is equipped to handle automatic jar feeding, measuring, filling, weight feedback, automatic correction, and other tasks, making it ideal for filling powdered materials.

Working Principle

- Two fillers, one for quick and 80% target weight filling and the other to gradually supplement the remaining 20%.

- Two load cells, one after the fast filler to detect how much weight the slow filler needs to supplement and one after the slow filler to remove reject.

Composition:

Highlights Include:

1. A touch screen, a PLC control system, and an easy-to-use mode of operation.

2. Rotary type, two weighing and detection sets, and real-time feedback to ensure that no defective products are produced during the packaging process.

3. The jars can be precisely positioned by the automatic turntable, resulting in no bottle, no filling. Two sets of vibration devices effectively reduce material volume.

4. The structure's overall design is reasonable. There are no dead corners to be cleaned. The jar specification can be easily and quickly modified.

5. It is intended to be used as a secondary supplement after weighing to significantly improve accuracy and speed.

6. Jar peeling and weight verification are automated. A trace of a circular supplement.

7. Precision planetary reducer, accurate positioning, and high precision Panasonic servo motor drive screw and rotary operation.

8. With a lifting jar and two sets of vibration and dust cover devices, it is completely sealed and filled.

Application Industry:

Specification:

|

Measurement method |

second supplement after filling |

|

Container size |

cylindrical container φ50-130 (replace the mold) 100-180mm high |

|

Packing weight |

100-1000g |

|

Packaging accuracy |

≤± 1-2G |

|

Packaging speed |

≥40-50 jars/min |

|

Power supply |

three-phase 380V 50Hz |

|

Machine power |

5kw |

|

Air pressure |

6-8kg/cm2 |

|

Gas consumption |

0.2m3/min |

|

Machine weight |

900kg |

|

A set of canned molds will be sent along with it |

|

Configuration:

|

Name |

Brand |

Origin |

|

PLC |

Siemens |

Germany |

|

Touch Screen |

Siemens |

Germany |

|

Filling Servo Motor |

Speecon |

Taiwan |

|

Filling Servo Drive |

Speecon |

Taiwan |

|

Mixing Motor |

CPG |

Taiwan |

|

Rotary Servo Motor |

Panasonic |

Japan |

|

Rotary Servo Drive |

Panasonic |

Japan |

|

Rotary Precision Planetary Reducer |

Mdun |

Taiwan |

|

Conveyor Motor |

GPG |

Taiwan |

|

Breaker |

Schneider |

France |

|

Contactor |

Schneider |

France |

|

Intermediate Relay |

Schneider |

France |

|

Thermal Overload |

Schneider |

France |

|

Air Cylinder |

AirTAC |

Taiwan |

|

Magnetic Valve |

AirTAC |

Taiwan |

|

Water-oil separator |

AirTAC |

Taiwan |

|

Material Level Sensor |

Autonics |

South Korea |

|

Material level Safety Sensor |

Bedook |

Germany |

|

Photoelectric switch |

Bedook |

Germany |

|

Load Cell |

METTLER TOLEDO |

USA |

Details:

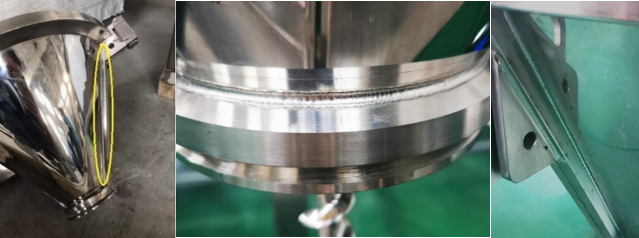

Half-Open Hopper

This level split hopper is easy to open and maintain.

Hanging Hopper

The combined hopper is ideal for very fine powder because there is no gap in the lower part of the hopper.

Screw Type

There are no gaps for the powder to hide in, and cleaning is simple.

The entire machine, including the base and motor holder, is made of SS304, which is stronger and of higher quality.

Cleaning is easy with full welding, including the hopper edge.

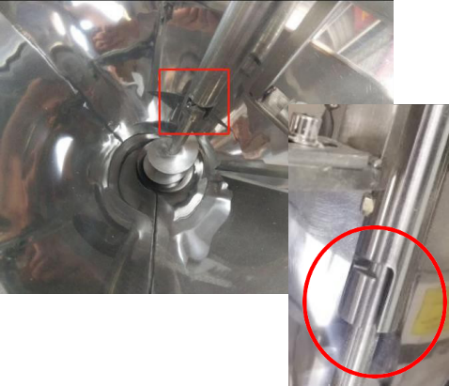

Dual heads filler

1. The primary filler will rapidly reach 85% of the target weight.

2. The assistant filler will precisely and gradually replace the left 15%.

3. They work together to achieve high speeds while maintaining precision.

Vibration & weighing

1. The vibration is connected to the can holder and is located between two fillers.

2. Two load cells, denoted by blue arrows, are vibration-isolated and will not affect accuracy. The first weighs the current weight after the first main filling, and the second determines whether the final product has reached the target weight.

Reject Recycling

Before being accepted for a second supply, rejects will be recycled and added to empty can lines.

According to the auger filler principle, the volume of powder brought down by the auger turning one circle is fixed. As a result, different auger sizes can be used to achieve higher accuracy and save time in different filling weight ranges. There is an auger tube for each auger size. For example, dia. The 38mm screw is ideal for filling 100g-250g containers.

Other Suppliers:

Hang Type

Powder will be hidden inside the hang connection part, making it difficult to clean and polluting even new powder.

There is a gap at the welding site when there is no full welding, which is easy to conceal powder, difficult to clean, and may pollute new material.

The motor holder is not made of stainless steel 304.

Cup Size and Filling Range

|

Order |

Cup |

Inner Diameter |

Outer Diameter |

Filling Range |

|

1 |

8# |

8mm |

12mm |

|

|

2 |

13# |

13mm |

17mm |

|

|

3 |

19# |

19mm |

23mm |

5-20g |

|

4 |

24# |

24mm |

28mm |

10-40g |

|

5 |

28# |

28mm |

32mm |

25-70g |

|

6 |

34# |

34mm |

38mm |

50-120g |

|

7 |

38# |

38mm |

42mm |

100-250g |

|

8 |

41# |

41mm |

45mm |

230-350g |

|

9 |

47# |

47mm |

51mm |

330-550g |

|

10 |

53# |

53mm |

57mm |

500-800g |

|

11 |

59# |

59mm |

65mm |

700-1100g |

|

12 |

64# |

64mm |

70mm |

1000-1500g |

|

13 |

70# |

70mm |

76mm |

1500-2500g |

|

14 |

77# |

77mm |

83mm |

2500-3500g |

|

15 |

83# |

83mm |

89mm |

3500-5000g |

Production Processing:

Company Profile:

Certificates:

FAQ:

1. Are you a manufacturer of auger fillers?

Shanghai Tops Group Co., Ltd. is a leading auger filler manufacturer in China with over ten years of experience in the packing machine industry.

2. Is your auger filler CE certified?

Not only does the filler have a CE certificate, but so do all our machines.

3. How long does it take for the auger filler to arrive?

It takes 7–10 days to produce a standard model. Your customized machine can be completed in 30–45 days.

4. What is your company's service and warranty policy?

LIFE-LONG SERVICE, TWO-YEAR WARRANTY, THREE-YEAR ENGINE WARRANTY (Warranty service will be honored if the damage is not caused by human or improper operation.)

Provide accessory parts at a reasonable price.

Update configuration and program regularly

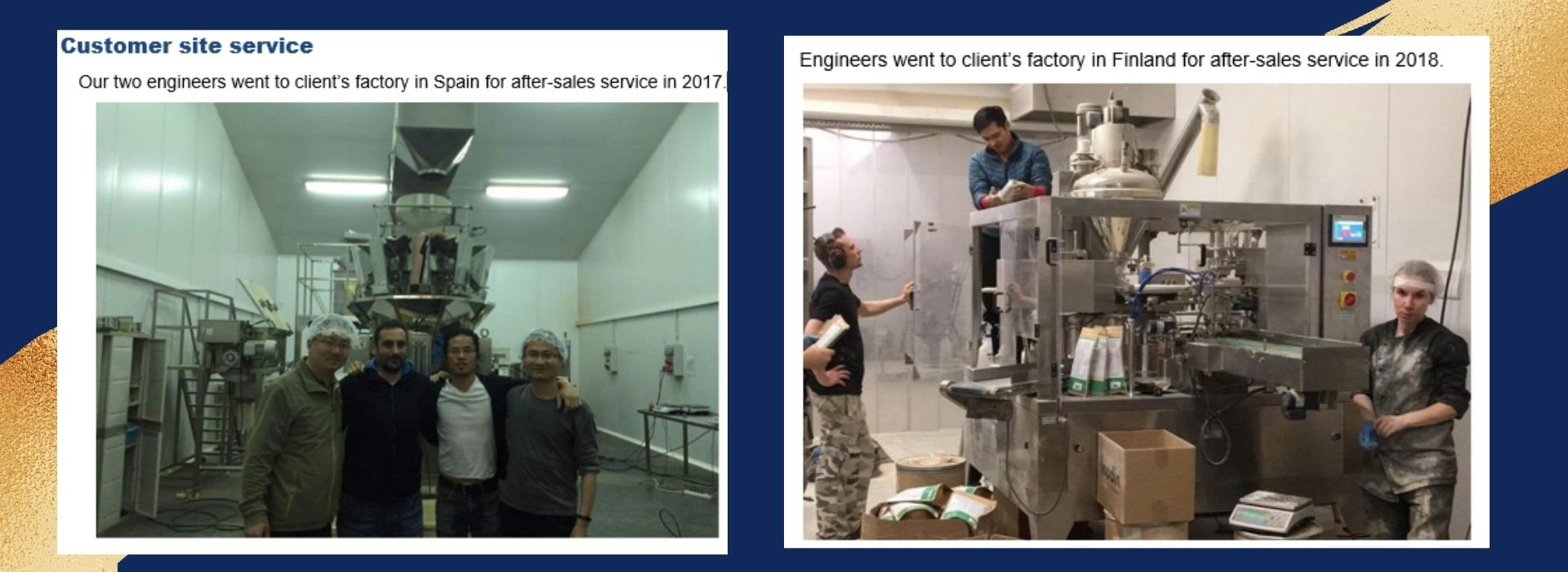

Site service or online video service that responds to any question within 24 hours

You can choose from the following payment terms: L/C, D/A, D/P, T/T, Western Union, Money Gram, and PayPal.

We accept all contract terms for shipping, such as EXW, FOB, CIF, DDU, and so on.

5. Are you able to design and propose solutions?

We have a professional design team and an experienced engineer, of course. For Singapore Bread Talk, for example, we designed a bread formula production line.

6. What types of products can the auger filler handle?

It can handle all types of powder or granule weighing and filling and is widely used in food, pharmaceuticals, chemicals, and other industries.

7. How does an auger filler operate?

The powder volume reduced by turning the screw one round is fixed. The controller will calculate how many turns the screw must make to reach the target filling weight.