General Description

This series is designed to handle measurements, holding, filling, and weight selection. It can be integrated into a complete can-filling production line with other related machines and is suitable for filling a variety of products such as kohl, glitter powder, pepper, cayenne pepper, milk powder, rice flour, egg white powder, soy milk powder, coffee powder, medicine powder, essence, and spices.

Machine usage:

--This machine is suitable for many kinds of powder such as:

--Milk powder ,flour ,rice powder ,protein powder ,Seasoning powder, chemical powder, medicine powder,coffee powder, soy flour Etc.

Filling Products Samples:

Baby Milk Powder Tank

Cosmetic Powder

Coffee Powder Tank

Spice Tank

Features

• Easily to wash. Stainless steel structure, hopper can open.

• Stable and reliable performance. Servo- motor drives auger, Servo- motor controlled turntable with stable performance.

• Easy To Use Easily. PLC, touch screen and weighing module control.

• With pneumatic can lifting device to assure the material not spilling out when filling On-line weighing device

• Weight-chosen device , to assure each product be qualified, and get rid of the unqualified filled cans

• With adjustable height-adjustment hand wheel at reasonable height, easy to adjust the head position.

• Save 10 sets of formula inside the machine for later use

• Replacing the auger parts, different products ranging from fine powder to granule and different weight can be packed Have one stir on the hopper, assure the powder fill in the auger.

• Chinese/English or custom your local language in the touch screen.

• Reasonable mechanical structure, easy to change size parts and clean up.

• Through changing accessories, the machine is suitable for various powder products.

• We use famous brand Siemens PLC, Schneider electric, more steady.

Technical Parameter:

| Model |

TP-PF-A301 |

TP-PF-A302 |

| Container Size |

Φ20-100mm;H15-150mm |

Φ30-160mm;H50-260mm |

| Control system |

PLC & Touch Screen |

PLC & Touch Screen |

| Packing Weight |

1 - 500g |

10-5000g |

| Packing Accuracy |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 500g, ≤±1%; >500g, ≤±0.5% |

| Filling Speed |

20-50 bottles per min |

20-40 bottles per min |

| Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

| Total Power |

1.2 KW |

2.3KW |

| Air Supply |

6kg/cm2 0.05m3/min |

6kg/cm2 0.05m3/min |

| Total Weight |

160kg |

260kg |

| Hopper |

Quick disconnecting hopper 35L |

Quick disconnecting hopper 50L |

Detailed

1.Quick disconnecting hopper

2. Level split hopper

Centrifugal device for easy flowing products,to ensure the precise filling accuracy

Pressure forcing device products,for non-flowing to ensure precise filling accuracy

Process

Put Bag/Can(Container) On The Machine → Container Raise → Fast Filling, Container Declines → Weight Reaches The Pre-Set Number → Slow Filling → Weight Reaches The Goal Number → Take The Container Away Manually Note: The Pneumatic Bag-Clamp Equipment And Can-Hold Set Is Optional ,They Are Suitable For Can Or Bag Filling Separately.

Two Filling Modes Can Be Inter-Changeable, Fill By Volume Or Fill By Weight. Fill By Volume Featured With High Speed But Low Accuracy. Fill By Weight Featured With High Accuracy But Low Speed.

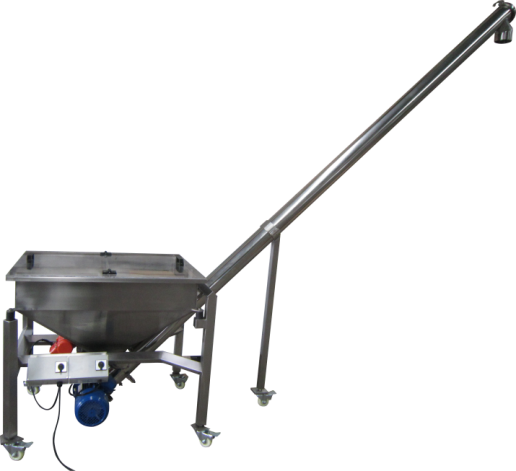

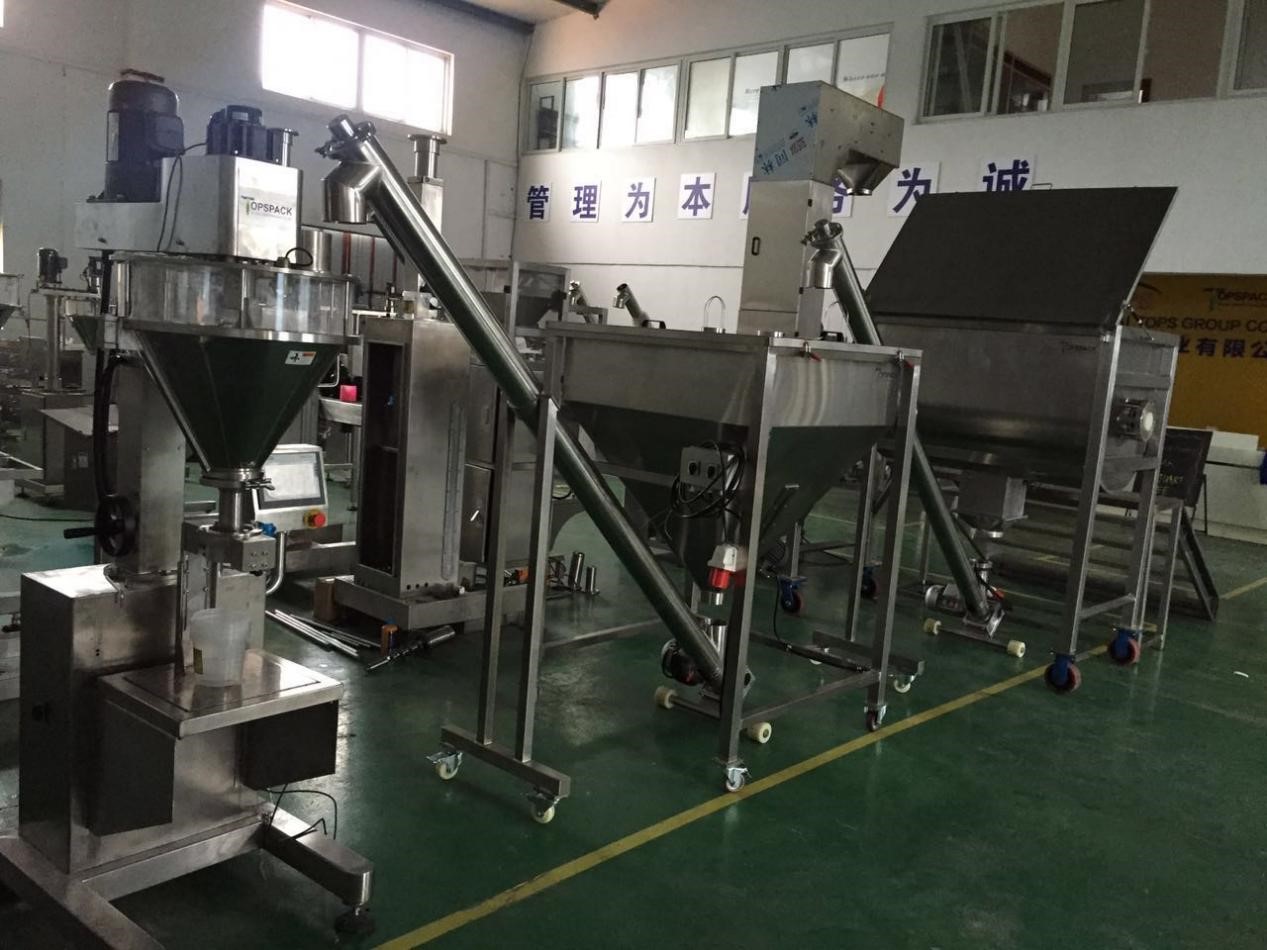

Other optional equipments for working with auger filling machine:

Auger Screw conveyor

Unscrambling Turning Table

Powder Mixing Machine

Can Sealing Machine

Our Certification

Factory Show

About Us:

Shanghai Tops Group Co., Ltd. Which is a professional enterprise of designing, manufacturing, selling powder pellet packaging machinery and taking over complete sets of engineering.With the continuously explore, research and application of advanced technology, the company is developing, and have a innovative team composed of professional and technical personnel, engineers, sales and after-sales service people.Since the company founded, it has successfully developed several series, dozens of varieties of packaging machinery and equipment, all the products meet the GMP requirements.

Our machines are widely used in variety industries of food, agriculture ,industry, pharmaceticals and chemicals, etc. With many years’ development, we have built our own technician team with innovative technicians and marketing elites, and we sucessfully develop many advancedd products as well as help customer design series of package production lines. Our machines are all strictly comply with the National Food Safety Standard, and machines have CE certificate.

We are struggling to be the“first leader”among the same range of fileds of packaging machinery. On the way to success, we need your utmost support and ccooperation. Let’s work hard altogether and make much greater success!

Our Team:

Our Service:

1) Professional advice and rich experience help to choose machine.

2) Lifelong maintainance and considerate technical support

3) Technicians can be sent to abroad to install.

4) Any problem before or after delivery, you could find and talk with us anytime.

5) Video / CD of test running and installation, Maunal book, tool box sent with machine.

Our Promise

Top and consistent quality, Reliable and excellent after-sale service!

Note:

1. Quotation:

2. Delivery Period: 25 days after receipt of down payment

3. Payment Terms: 30%T/T as deposit + 70%T/T balance payment before delivery.

3. Guarantee Period: 12 months

4. Package: seaworthy plywood carton

FAQ:

1. Can your machine meet our needs well?

A: After receiving your inquiry, we will confirm your

1. Your pack weight per pouch, pack speed, pack bag size(it is the most important).

2. Show me your unpack productions and pack samples picture.

And then give you the proposal according to your specific requirement. Every machine is customized to meet your needs well.

2. Are you factory or trading company?

A: We are the factory, have more than 13 years experience, mainly produce powder and grain pack machine.

3. How can we make sure about the machine quality after we put the order?

A: Before delivery, we will send you the pictures and videos for you to check the quality, and also you can arrange for quality checking by yourself or by your contacts in Shanghai.

4. What is your terms of packing?

A: Generally, we pack our goods in wooden cartons.

5. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. For big order, we accept L/C at sight.

6. How about your delivery time?

A: Generally, it will take 15 to 45days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.