-

The Best Way in Using Forklifts

We all know that the best way in using forklifts is for lifting those larger-size ribbon blender to a safest and easiest way of transport. Materials and equipment are required: ...Read more -

The Single-Shaft Paddle Mixer and its qualities and importance

The single-shaft paddle mixer can be used to mix powder and powder, granule and granule, or add a little liquid. It is commonly used with granular materials like almonds, beans and sugar. The machine’s inside has wide-ranging angles of blades that throw up the material, causing cross-mixin...Read more -

The important usage of a Round Bottle Automatic Labeling Machine

This TP-DLTB-A is inexpensive, autonomous, and simple to use. It possesses a touch screen with automatic training and programming on it. Those different task settings are stored on an internal microchip, and the changeover is very quick and easy. Applying a self-adhesive sticker label on the pr...Read more -

The advantages of using a Vertical Ribbon Mixer

This process of a vertical ribbon mixer is to mix materials inside of it. The vertical ribbon mixer performs a high quality in mixing dry, moist and viscous materials. This mixer is perfect for the food industry where it is conform...Read more -

The accessible components for an Automatic Powder Auger Filling Machine

This technique can put a great deal of powder into bottles and bags. Due to its unique professional design, it is suitable for fluidic or low-fluidity material...Read more -

The general characteristics and functional concepts of Single-arm Rotary Mixer

Single-Arm rotary Mixer is an example type of a mixing machine which uses one spinning arm to mix and combine substances. It is recurrently used in research institutions, small production operations and specialized applications tha...Read more -

The importance and the use of a Single Shaft Paddle Mixer

The single shaft paddle mixer can be used to mix powder and powder, granule and granule, or add a little amount of liquid. It is frequently used with granule materials such as nuts, beans, and seeds. The machine’s inside has varying angles of blades that throw up the material, causing cros...Read more -

Patent Technology of Discharge Valve and Shaft Sealing

All mixer users struggle with leakage, which occurs in different ways: from powder inside to outside, dust from outside to inside, from sealing material to contaminating powder and powder inside to outside at discharge. In order to avoid issues from users when mixing mat...Read more -

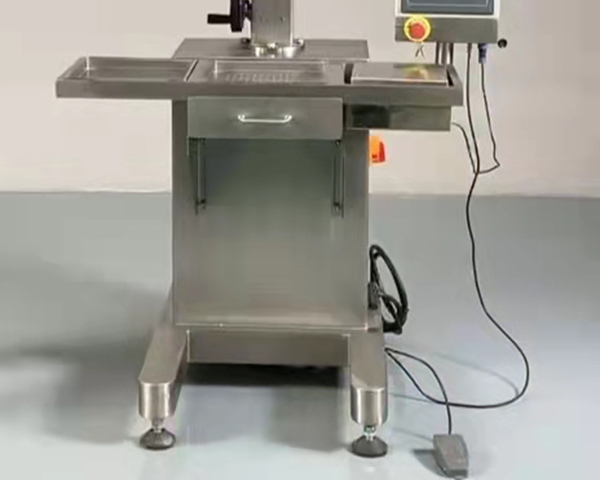

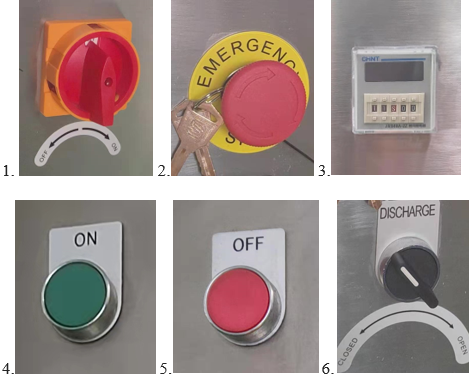

How should we operate the Control Panel?

The following are the operational guidelines of a control panel: 1. In order to turn the power on/off, press the main power switch to the desired position. 2. If you wan...Read more -

A Paddle Mixer: For Delicate Mixing and Blending of Materials

For delicate mixing and blending of materials, paddle mixers are frequently employed in a variety of industries. A paddle mixer's efficiency is influenced by a number of process variables that can be changed to improved more in mixing results. The following are some cru...Read more -

Why Capping Machines are crucial for safety capping or closing containers?

In the packaging industry, capping machines are crucial for safety capping or closing containers. A capping machine’s design incorporates a number of parts and systems to guarantee an accurate and dependable cap application. These are the following crucial elements of capping machine design...Read more -

The Specialized Applications of a Ribbon Mixer

“Ribbon Mixers” have a specialized applications in a variation of industries, where accurate and efficient mixing is critical. Here are some specific illustrations of specialized Ribbon Mixer applications: Food industry: This machine is intended to mix dry ingredients such as flour, sugar, spic...Read more